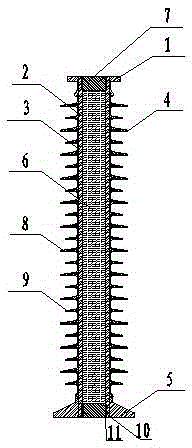

Hollow paste-injected post insulator employing vacuum impregnated fiber

The technology of pillar insulator and fiber column is applied in the field of vacuum glue-impregnated fiber hollow plastering pillar insulator, which can solve the problems of affecting electrical performance, easy to explode, poor sealing performance, etc., to improve electrical performance, not easy to fall off, and strengthen sealing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The preparation method of the vacuum glue-impregnated fiber hollow paste injection post insulator described in this embodiment includes the following steps:

[0041] (1) Flange preheating: first put the upper and lower flanges into a constant temperature furnace at 75°C for 1.5 hours;

[0042] (2) Deploying adhesive: place the bisphenol A epoxy resin in a constant temperature furnace at 55°C for 25 minutes to soften the bisphenol A epoxy resin; add oxidation to the bisphenol A epoxy resin at a ratio of 95:35 aluminum curing agent to make the adhesive stock solution; acetone and industrial alcohol are mixed in a ratio of 1:1 to make a dilution; the above-mentioned adhesive stock solution and the dilution are diluted and stirred in a ratio of 2:1, and the final The glue solution is stored in a furnace at a temperature of 65°C;

[0043] (3) Assembly: The sealing cover and the inner sides of the two ends of the vacuum glue-impregnated fiber column are tightly sealed throug...

Embodiment 2

[0052] The preparation method of the vacuum glue-impregnated fiber hollow paste injection post insulator described in this embodiment includes the following steps:

[0053] (1) Flange preheating: first put the upper and lower flanges into a constant temperature furnace at 70°C for 2 hours;

[0054] (2) Deploying adhesive: place the bisphenol A epoxy resin in a constant temperature furnace at 50°C for 30 minutes to soften the bisphenol A epoxy resin; add oxidation to the bisphenol A epoxy resin at a ratio of 90:40 aluminum curing agent to make the adhesive stock solution; acetone and industrial alcohol are mixed in a ratio of 1:1 to make a dilution; the above-mentioned adhesive stock solution and the dilution are diluted and stirred in a ratio of 2:1, and the final The glue solution is stored in a furnace at a temperature of 60°C;

[0055] (3) Assembly: The sealing cover and the inner sides of both ends of the vacuum glue-impregnated fiber column are tightly sealed by threads,...

Embodiment 3

[0064] The preparation method of the vacuum glue-impregnated fiber hollow paste injection post insulator described in this embodiment includes the following steps:

[0065] (1) Flange preheating: first put the upper and lower flanges into a constant temperature furnace at 85°C for 1 hour;

[0066] (2) Deploying adhesive: put the bisphenol A epoxy resin in a constant temperature furnace at 60°C for 20 minutes to soften the bisphenol A epoxy resin; add oxidation to the bisphenol A epoxy resin at a ratio of 100:30 aluminum curing agent to make the adhesive stock solution; acetone and industrial alcohol are mixed in a ratio of 1:1 to make a dilution; the above-mentioned adhesive stock solution and the dilution are diluted and stirred in a ratio of 2:1, and the final The glue solution is stored in a furnace at a temperature of 75°C;

[0067] (3) Assembly: The sealing cover and the inner sides of both ends of the vacuum glue-impregnated fiber column are tightly sealed by threads, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com