Composition of lotus flavones

A technology of lotus leaf flavonoids and composition, which is applied in the field of natural medicines and can solve problems such as separation and purification processes that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

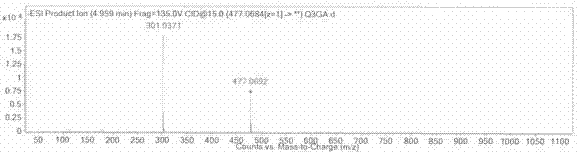

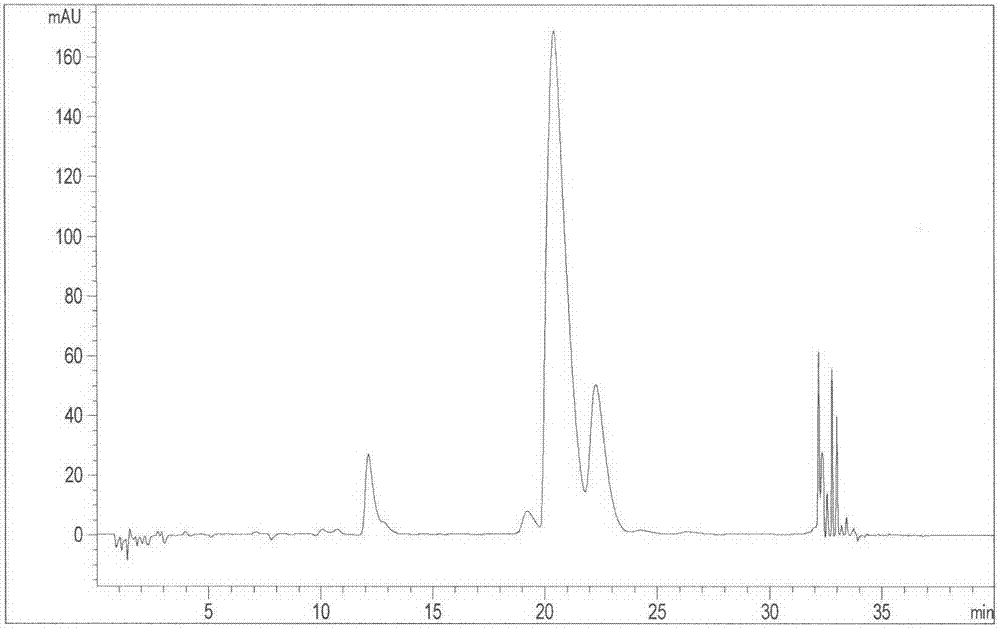

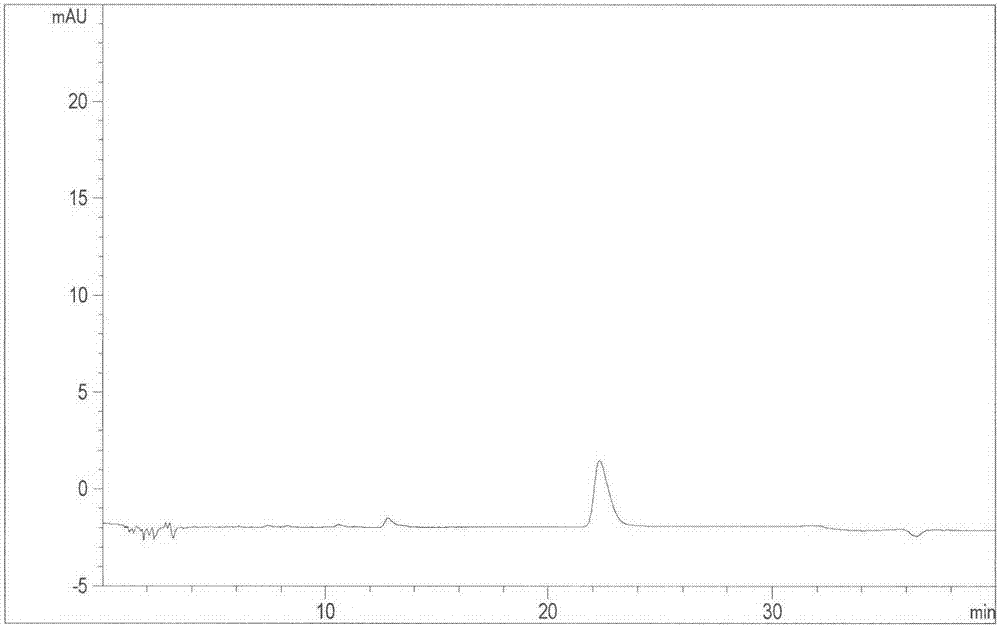

Image

Examples

Embodiment 1

[0099] The method steps of adopting macroporous adsorption resin to separate and purify a kind of lotus leaf flavonoid involved in the present invention are as follows:

[0100] (1) drying and pulverizing the lotus leaf to obtain the lotus leaf meal;

[0101] (2) Take by weighing 300g lotus leaf coarse powder, adopt 1: 30 (W / V) solid-liquid ratio to add 9 liters of 50% ethanol solution in this lotus leaf powder, 90 ℃ of hot reflux extraction time 3h, repeat leaching 3h The second time, the extracts were combined and then concentrated and dried to obtain the extract. The flavonoid weight content in the extract was 3%; the above extract was ultrasonically dissolved in distilled water and then dynamically loaded with macroporous adsorption resin LX-60 for purification;

[0102] (3) Use 10 times the column bed volume of distilled water and 25% ethanol to elute, and fully wash away a large amount of water-soluble impurities such as polysaccharides and proteins;

[0103] (4) Elute ...

Embodiment 2

[0107] (1) drying and pulverizing the lotus leaf to obtain the lotus leaf meal;

[0108] (2) Take 200g of lotus leaf coarse powder, add 8 liters of 70% ethanol solution to the lotus leaf coarse powder with a solid-liquid ratio (W / V) of 1:40, heat reflux at 80°C for 4 hours, and repeat the extraction 2 times, the extracts are combined and then concentrated and dried to obtain the extract, the flavonoid weight content in the extract is 3%. The above extracts were ultrasonically dissolved in distilled water and then purified by dynamic loading of macroporous adsorption resin LX-5;

[0109] (3) Elute with 8 times the column bed volume of distilled water and 18% ethanol to fully wash away a large amount of water-soluble impurities such as polysaccharides and proteins;

[0110] (4) Elute the macroporous resin with 30% ethanol;

[0111] (5) The 30% ethanol eluate was concentrated, freeze-dried, pulverized, and mixed uniformly to obtain a powder, and the weight content of quercetin-...

Embodiment 3

[0114] (1) lotus leaf is dried and pulverized to form lotus leaf meal;

[0115] (2) Take 400g of lotus leaf coarse powder, add 8 liters of 60% ethanol solution to the lotus leaf coarse powder with a material-to-liquid ratio (W / V) of 1:20, heat reflux at 70°C for 2 hours, and repeat the extraction 4 times, the extracts were combined, concentrated and dried to obtain the extract, and the flavonoid weight content in the extract was 4%. The above extracts were ultrasonically dissolved in distilled water and then purified by dynamic loading of macroporous adsorption resin AB-8;

[0116] (3) elution with 9 times column bed volume of distilled water and 20% ethanol to fully wash away a large amount of water-soluble impurities such as polysaccharides and proteins;

[0117] (4) adopt 32% ethanol to elute the macroporous resin;

[0118] (5) The 32% ethanol eluate was concentrated, dried under vacuum and reduced pressure, pulverized, and uniformly mixed to obtain a powder. The weight c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com