Preparation method for Cu-base methanol-synthesizing catalyst large-specific-surface-area carrier

A technology of methanol synthesis and large specific surface, applied in the preparation of hydroxyl compounds, organic compounds, chemical instruments and methods, etc., can solve the problems of low thermal stability, short life, and small specific surface of synthetic methanol catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

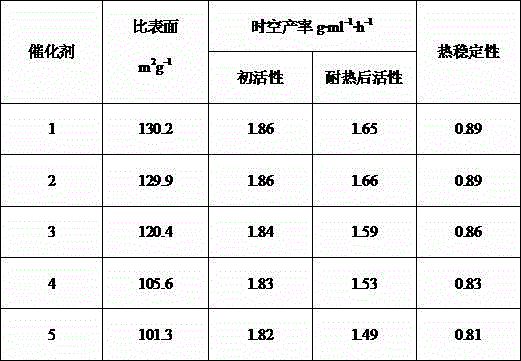

example 1

[0011] In the aluminum hydroxide gel-like carrier precursor obtained by reacting NaOH as a precipitating agent with aluminum nitrate, add 1% surface dispersant gum arabic, and treat it under ultrasonic wave for 30 minutes to prepare the carrier. Mixing with the parent body, filtering, drying, roasting, molding and other processes were respectively made into copper-based methanol synthesis catalyst sample 1.

example 2

[0013] In the aluminum hydroxide gel-like carrier precursor obtained by reacting ammonia water as a precipitating agent with aluminum nitrate, add 1.5% surface dispersant gum arabic, and treat it under the action of ultrasonic waves for 20 minutes to prepare the carrier. Mixing with the parent body, filtering, drying, roasting, molding and other processes were respectively made into copper-based methanol synthesis catalyst sample 2.

example 3

[0015] The carrier was prepared by adding 1% surface dispersant gum arabic to the aluminum hydroxide gel carrier precursor obtained by reacting NaOH as a precipitating agent with aluminum nitrate. Mixing with the parent body, filtering, drying, roasting, molding and other processes were respectively made into copper-based methanol synthesis catalyst sample 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com