A liquid preparation tank for removing iron and sterilizing oilfield sewage

An oilfield sewage and liquid dispensing tank technology, applied in water/sewage treatment, reduced water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of complex process, high cost, low sterilization efficiency, etc., and achieve a simple operation process. , Low labor intensity, complete sterilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

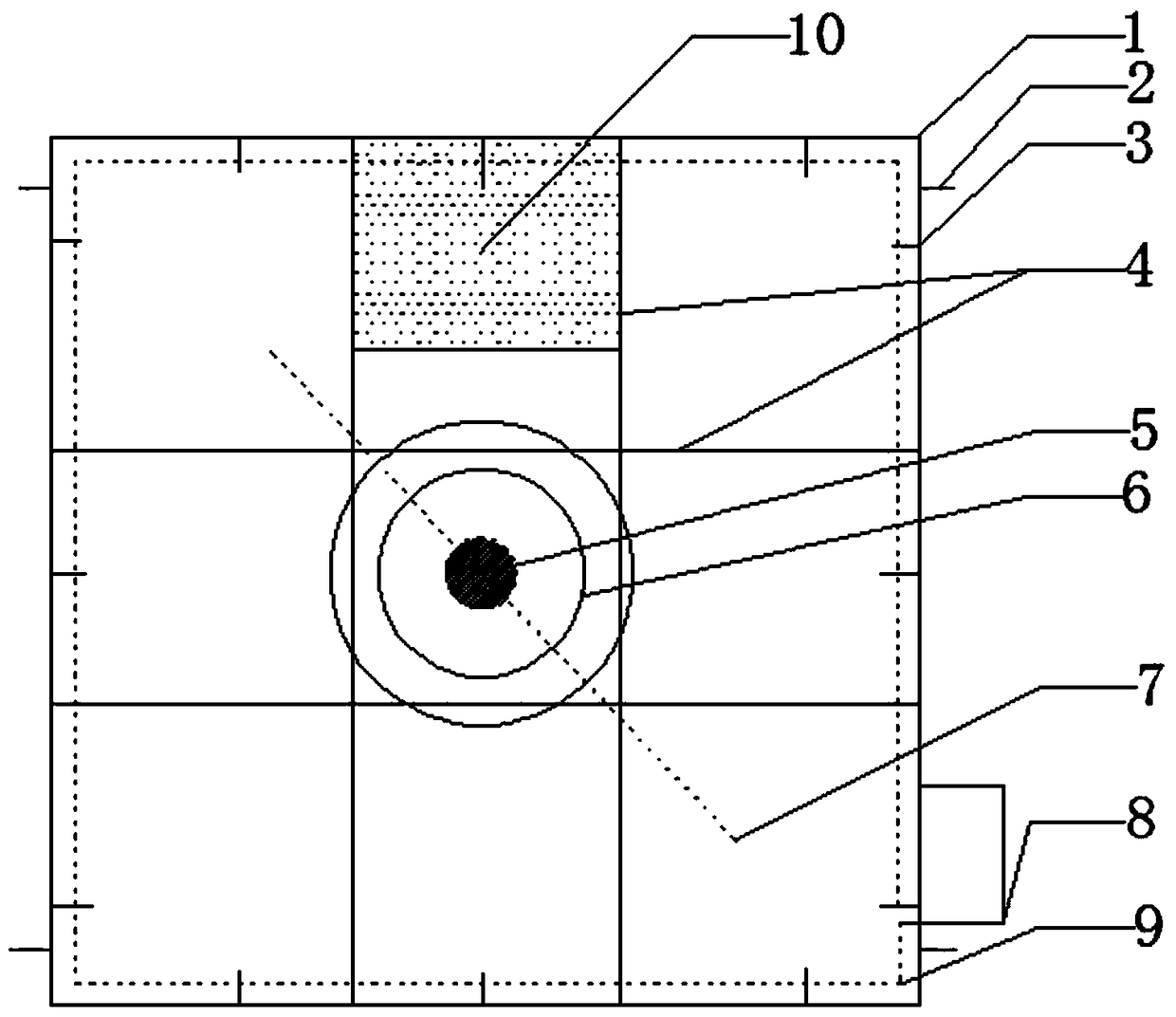

[0030] This embodiment provides a liquid mixing tank for removing iron and sterilizing oil field sewage (the schematic diagram of the section is as follows figure 1 shown), the liquid distribution tank includes: tank body 1, hook 2, card slot 3, protective frame 4, rotating shaft 5, motor 6, straight stirring blade 7, oxygen pump 8, hose with mesh 9, distribution Liquid port 10;

[0031] in,

[0032] The tank body 1 is a square;

[0033] The protective frame 4 includes four horizontal frames, which are welded to the inner wall of the tank body 1 in a well-shaped arrangement. The protective frame 4 is provided with an agitator and a protective steel mesh. The agitator includes a rotating shaft 5, a motor 6 and a flat surface. Straight stirring blade 7; on the protective steel mesh, a liquid distribution port 10 is provided near the inner wall of the tank;

[0034] There are 12 card slots 3 welded in the tank body 1, and each surface of the tank body has 3 card slots respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com