Intelligent control method and control equipment for steam curing of cement concrete

A cement concrete and steam curing technology, which is applied in the field of cement concrete steam curing, can solve the problems of poor curing quality, unscientific, large water consumption, etc., and achieve the effect of avoiding the risk of curing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below by specific examples.

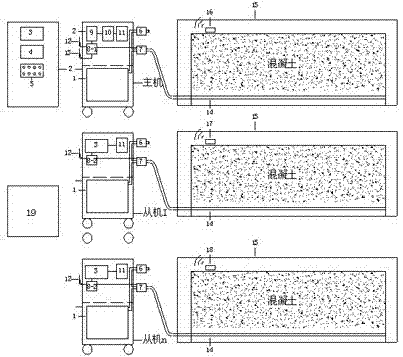

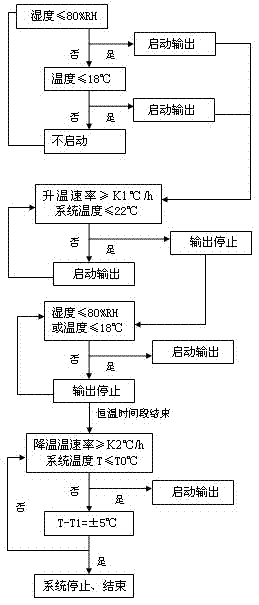

[0050] The present invention includes two intelligent control methods for steam curing of cement concrete, which respectively correspond to concrete curing in warm southern regions in winter and standard concrete steam curing in northern severe cold regions. Among them, the first mode corresponds to southern winter, and the specific flow chart is as attached figure 1 shown; the second mode is suitable for the severe cold regions in the north, and the specific program flow chart is attached figure 2 As shown, the following control program is for the maintenance area of the master or a slave.

[0051] The concrete implementation steps of the present invention in actual working process are as follows:

[0052] Step 1: Device Selection and Pairing

[0053] Cement concrete steam curing intelligent control equipment is attached image 3 And attached Figure 4 shown.

[0054] Choose how many ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com