Catalyst component used for olefin polymerization and catalyst used for olefin polymerization and application

A technology of olefin polymerization and catalyst, which is applied in the application field of catalyst in olefin polymerization reaction, can solve problems such as high melt mass flow rate, product separation problems, and overshooting, and achieve low melt mass flow rate and high polymerization activity , the effect of low isotactic index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] According to the present invention, the above-mentioned preparation method for the catalyst component of olefin polymerization comprises the following steps:

[0069] (1) Carrying out the first contact reaction between the oxirane compound shown in formula (4) and the titanium compound, the conditions of the first contact reaction include: the reaction temperature is -30°C to 50°C, the reaction time 2-30min;

[0070] (2) The magnesium compound shown in formula (1), formula (2) or formula (3) is carried out the second contact reaction with the product that step (1) obtains, and in described magnesium compound and the product that step (1) obtains Adding an internal electron donor in one or more time periods before, during and after the second contact reaction of the product,

[0071] (R 1 O) m MgT n Formula (1), MgX k (R 4 Oh) p (H 2 O) q Formula (2),

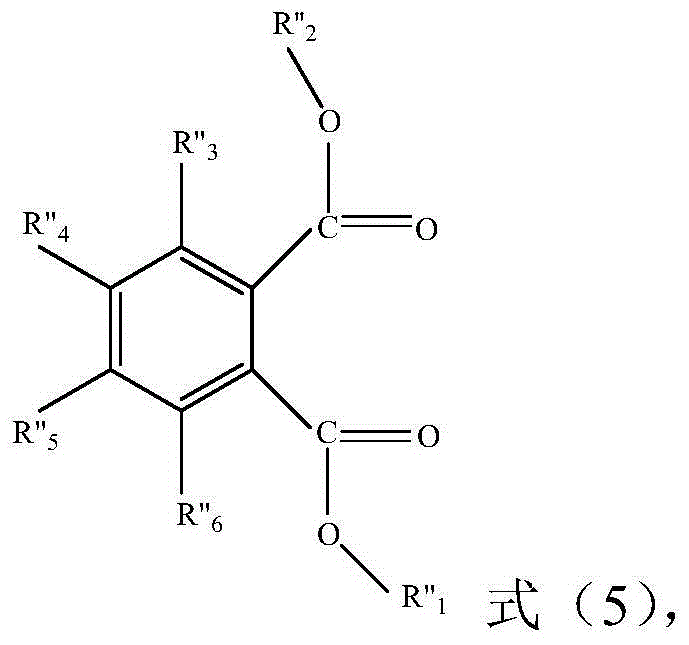

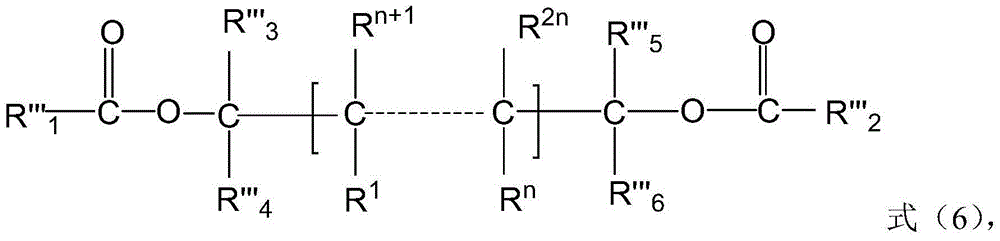

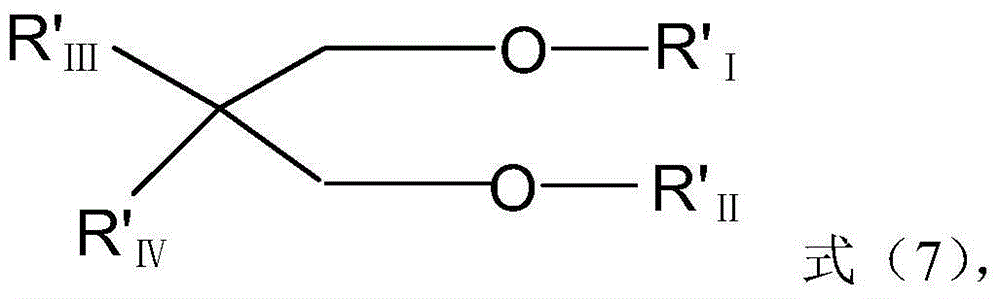

[0072] (R 5 O)Mg(OR 6 ) formula (3), Formula (4),

[0073] Among them, T is

[0074] R 1 and R 4 th...

preparation example 1

[0147] This preparation example is used to illustrate the catalyst component for olefin polymerization provided by the present invention and its preparation method.

[0148] (1) In a 1.6L reactor, add 200mL No. 5 white oil (Sigma-Aldrich Company), 8.0g (0.084mol) anhydrous magnesium chloride, 6g surfactant span80 (Sigma-Aldrich Company), 100mL (1.70mol ) ethanol, under stirring, the temperature was raised to 90°C. After reacting at constant temperature for 1 hour, the resulting mixture was stirred and dispersed for 30 minutes for emulsification. And add 25mL (0.32mol) epichlorohydrin in the obtained emulsification product, maintain temperature reaction 0.5 hour, carry out pressure filtration then, filter off liquid, wash 5 times with hexane, vacuum-dry, obtain magnesium compound A1, through infrared spectrum Law and 1 H-NMR method measures, magnesium compound A1 structural formula is as follows formula (9) expression (R 1 is ethyl, R 2 for hydrogen, R 3 is chloromethyl, X...

preparation example 2

[0152] This preparation example is used to illustrate the catalyst component for olefin polymerization provided by the present invention and its preparation method.

[0153] (1) The magnesium-containing compound is prepared according to the disclosed method of Example 1 in CN1718595A, specifically as follows:

[0154] In a stirred 150L reactor, 10kg (105mol) of magnesium chloride and 12.6kg (273mol) of ethanol were added into 60L of white oil with a viscosity of 30 centipoise (20°C) and reacted at 125°C for 2 hours. Then transfer the mixture of molten adduct and white oil to the medium of methyl silicone oil which has been preheated to 125°C; the viscosity of methyl silicone oil is 300 centipoise (20°C), and the amount of methyl silicone oil is 120L ; Stir at a speed of 200 rpm for 10-30 minutes to obtain a mixed solution. Introduce the mixed solution into a high-gravity rotating bed for dispersion, and introduce the dispersed mixed solution into a hexane medium that has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com