Polyurethane composite material for zero-pressure memory foam pulse pillow and preparation method of polyurethane composite material

A polyurethane composite material and zero-pressure-sensitivity technology, which is applied in the field of polymer materials, can solve problems that affect the doctor's diagnosis and treatment progress, patients' muscle tension, arm shaking, etc., and achieve the goal of reducing cumbersome operations, alleviating fatigue, and reducing energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

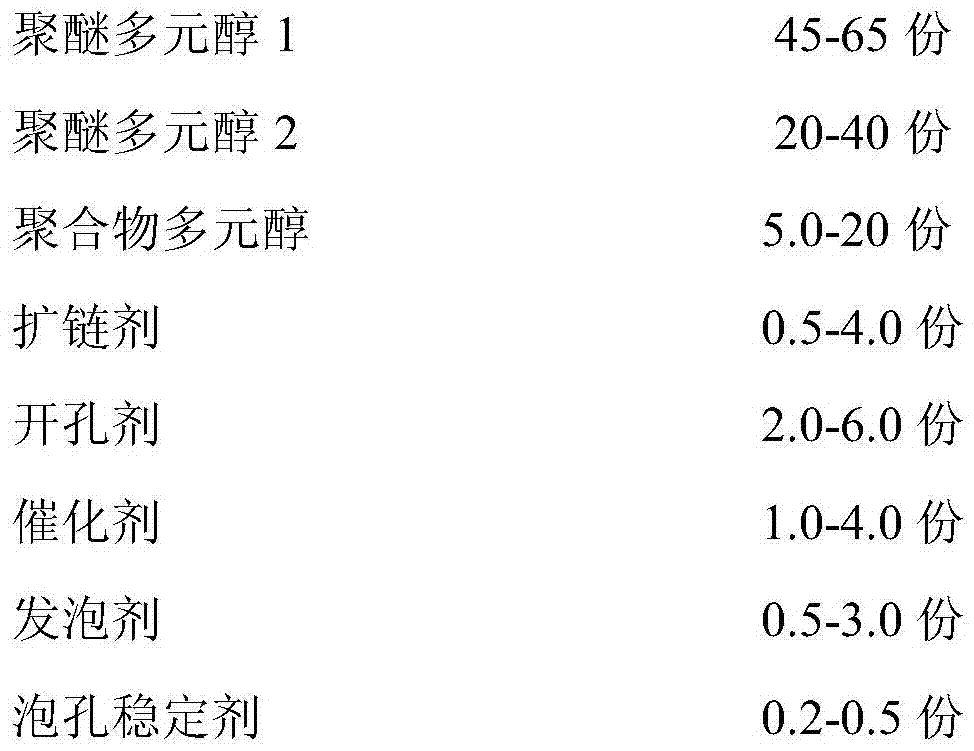

Embodiment 1

[0044] Preparation of component A materials: Weigh 50.0kg of polyether polyol EP-330NG, 30.0kg of slow rebound polyether polyol SR-308, 20.0kg of polymer polyol CHP-H45, shrink the chain extender Diethylene glycol is 2.0kg, cell opener SD-75 is 5.0kg, catalyst C-225 is 1.5kg, catalyst A-33 is 0.5kg, foam stabilizer AK-7703 is 0.5kg, blowing agent H 2 O is 0.35kg. Put the weighed polyether polyol, slow-rebound polyether polyol, and polymer polyol into the reactor for stirring, then put in the accurately measured chain extender, catalyst, foam stabilizer, and blowing agent respectively, and put them at room temperature Under physical stirring for 3.0 hours, samples were taken for testing, and if all testing indicators were met, the qualified product of component A was obtained, and the material was discharged from the reaction kettle and loaded into barrels for storage.

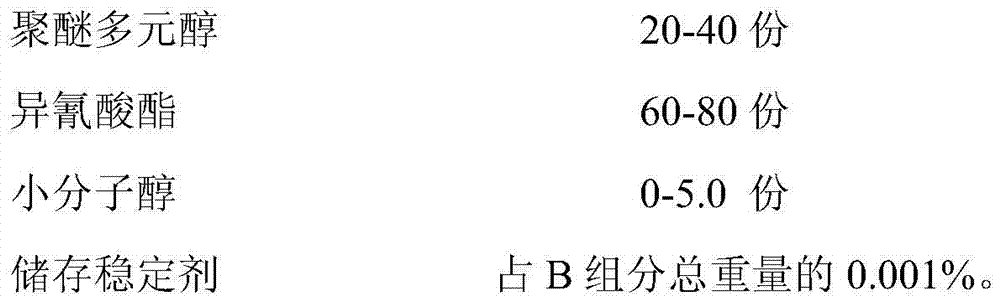

[0045]Preparation of component B materials: Put 30.0kg of polyether polyol EP-3600, 10.0kg of polyether pol...

Embodiment 2

[0048] Preparation of component A materials: weigh polyether polyol FA-703 to 65.0kg, slow rebound polyether polyol YNW-1070 to 20.0kg, polymer polyol POP45 to 25.0kg, chain extender ethylene glycol 0.5 kg, cell opener DK-12 is 5.0kg, catalyst A-33 is 3.0kg, cell stabilizer AK-7703 is 0.4kg, blowing agent H 2 O is 0.15kg and 141B is 2.5kg. Put the weighed polyether polyol, slow-rebound polyether polyol, and polymer polyol into the reaction kettle for stirring, and then put in the accurately measured expansion agent, catalyst, foam stabilizer, and blowing agent respectively, at room temperature Under physical stirring for 2.0 hours, sampling is carried out for detection, and the qualified product of component A is obtained when all detection indicators are met, and the material is discharged from the reaction kettle and loaded into a barrel for storage.

[0049] Preparation of component B materials: Put 20.0kg of polyether polyol EP-330NG and 0.5kg of propylene glycol into the...

Embodiment 3

[0052] Preparation of component A materials: weigh polyether polyol EP-330NG to 55.0kg, slow resilience polyether polyol SR-308 to 40.0kg, polymer polyol CHP-H45 to 5.0kg, chain extender butadiene Alcohol is 1.0kg, cell opener SD-75 is 3.0kg, catalyst C-225 is 0.5kg, A-33 is 2.0kg, cell stabilizer DC193 is 0.4kg, blowing agent H 2 O is 0.20kg, and 141B is 1.5kg. Put the weighed polyether polyol, slow-rebound polyether polyol, and polymer polyol into the reactor for stirring, then put in the accurately measured chain extender, catalyst, foam stabilizer, and blowing agent respectively, and put them at room temperature Under physical stirring for 2.0 hours, sampling is carried out for detection, and the qualified product of component A is obtained when all detection indicators are met, and the material is discharged from the reaction kettle and loaded into a barrel for storage.

[0053] Preparation of component B materials: Put 30.0kg of polyether polyol ED-28 and 5.0kg of dipro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com