Preparation method for polylactic acid-based alloy material with high strength and toughness

A technology of tough polylactic acid-based and alloy materials, which is applied in the field of preparation of polylactic acid-based alloy materials, can solve the problems of high brittleness and poor cushioning, and achieve the effects of promoting crystallization, improving toughness, and excellent uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

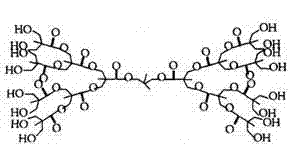

Image

Examples

specific Embodiment 1

[0023] A preparation method of a high-strength polylactic acid-based alloy material, which is formed by compounding main materials and auxiliary materials. The main materials include 123.3g hydroxyl-terminated polylactic acid, 73.8g hydroxyl-terminated hyperbranched polyester, and 49.3g ethylene-acrylic acid copolymer. 3.7g polycondensation catalyst, 4.9g nucleating agent, 3.5g antioxidant, 3.2g plasticizer DOP and 2.9g anti-ultraviolet agent UV531.

[0024] After fully drying all raw materials, blend at 60°C for 5-10 minutes in a high-speed blending machine, and then melt and blend in a twin-screw extruder. The processing temperature range is 190°C-210°C, and the screw speed is 400 rpm, the residence time is 2-3 minutes, the extrusion process is vacuumed, and the pressure is lower than 0.01MPa. Granular alloy materials are obtained after drying, cooling and pelletizing.

[0025] The molecular weight of the hydroxyl-terminated polylactic acid is between 100,000-300,000 g / mol,...

specific Embodiment 2

[0029] A preparation method of a high-strength polylactic acid-based alloy material, which is formed by compounding main materials and auxiliary materials. The main materials include 103.2g hydroxyl-terminated polylactic acid, 75.1g hydroxyl-terminated hyperbranched polyester, and 79.7g ethylene-acrylic acid copolymer. 4.2g polycondensation catalyst, 5.1g nucleating agent, 3.91g antioxidant, 3.52g plasticizer DOP and 3.28g anti-ultraviolet agent UV531.

[0030]After fully drying all raw materials, blend at 60°C for 5-10 minutes in a high-speed blending machine, and then melt and blend in a twin-screw extruder. The processing temperature range is 190°C-210°C, and the screw speed is 400 rpm, the residence time is 2-3 minutes, the extrusion process is vacuumed, and the pressure is lower than 0.01MPa. Granular alloy materials are obtained after drying, cooling and pelletizing.

[0031] The molecular weight of the hydroxyl-terminated polylactic acid is between 150,000-300,000 g / mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com