Vertical electrochemical cell setup for in situ photomechanical measurements

A battery device and optomechanical technology, applied in the direction of measuring devices, optical devices, measuring electricity, etc., can solve the problem of extremely high requirements on the optical path, and achieve the effect of light battery and low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

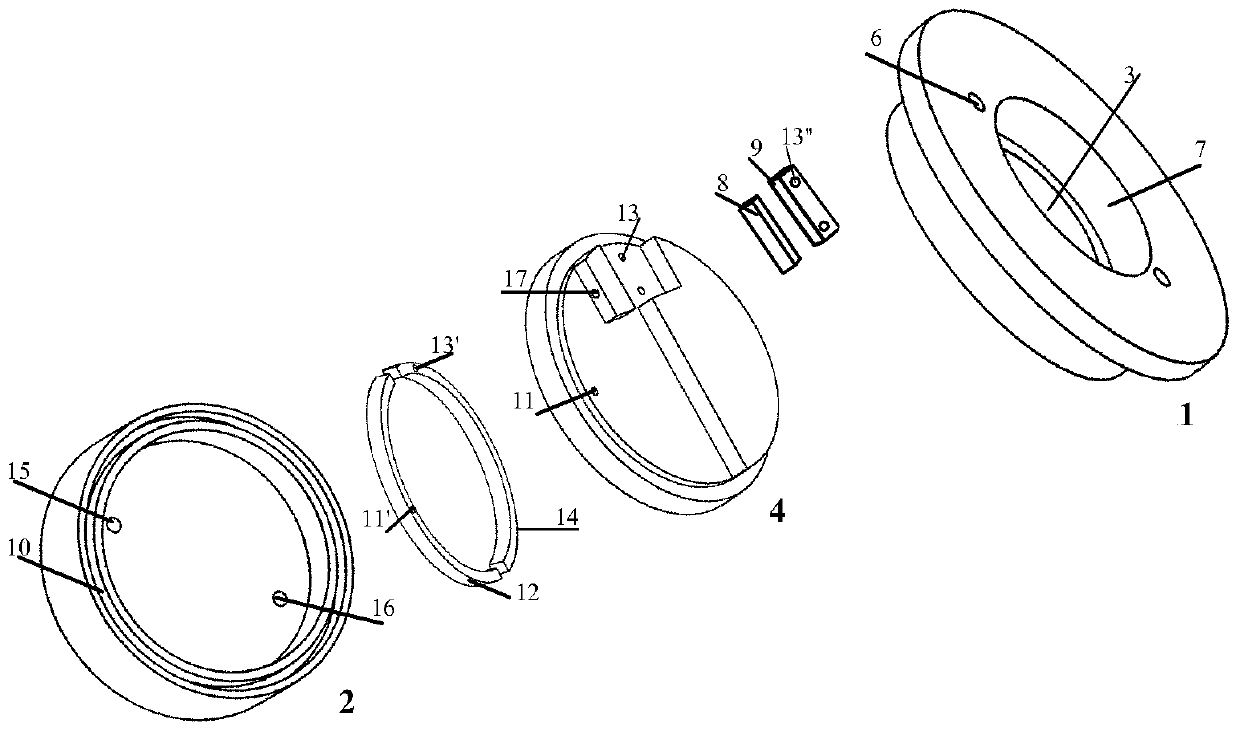

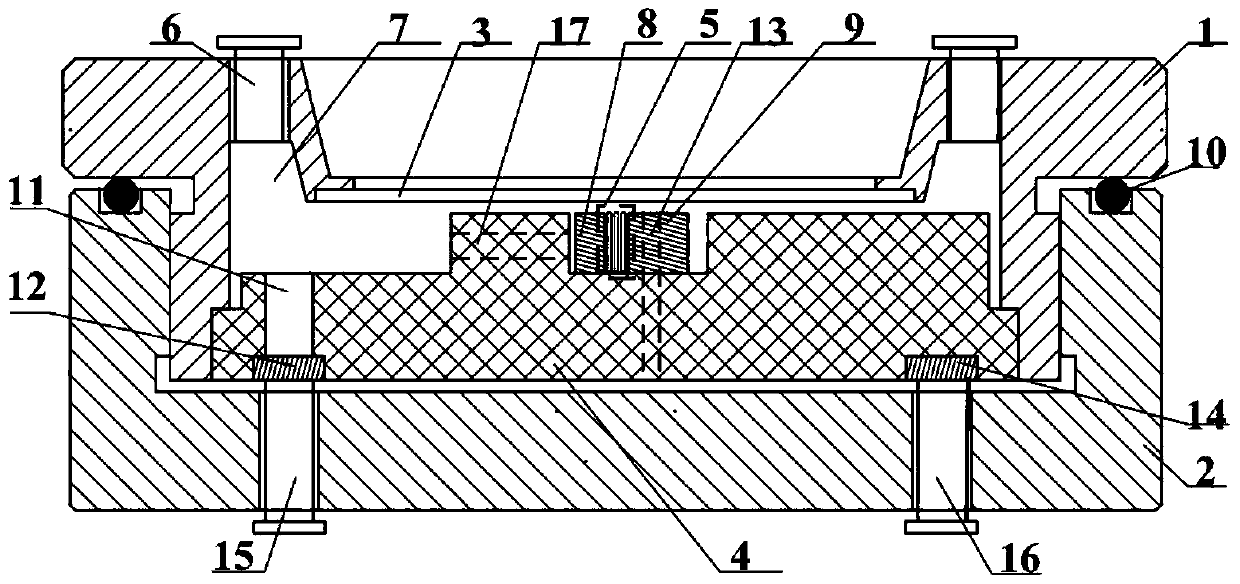

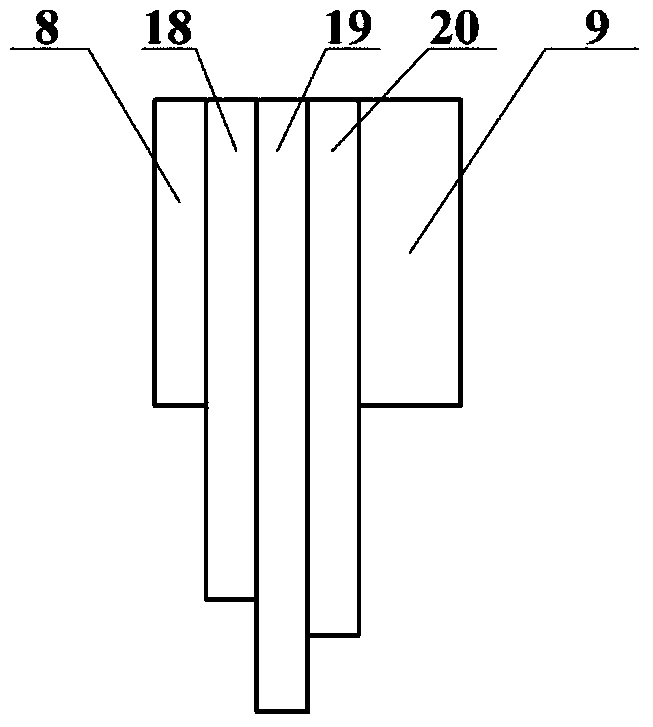

[0038] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0039] Such as figure 1 Shown: The electrochemical cell components include: the upper cover of the battery, the quartz window, the inner sleeve of the fixed electrode, the conductive ring, the electrode pressing piece and the lower cover of the battery. The battery upper cover, lower cover, and fixed electrode inner bushing are all made of nylon material, the quartz window is made of JGS1 quartz glass with high light transmittance, and the electrode pressing sheet, conductive ring, conductive screw, etc. are made of copper material.

[0040] The quartz window located in the center of the battery top cover is made of JGS1 high-transparency quartz glass, which is glued to the window (3) of the battery top cover (1) with epoxy resin to meet the light transmission requirements of optical measurement. The position of the quartz optical window is lower than the bottom of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com