MOEMS accelerometer based on planar ring cavity, and manufacturing method of the same

An accelerometer and annular cavity technology, which is applied in the field of optics and micro-electromechanical systems, can solve the problem that performance parameters such as resolution and sensitivity are not easily improved, and achieve the effect of improving sensitivity and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

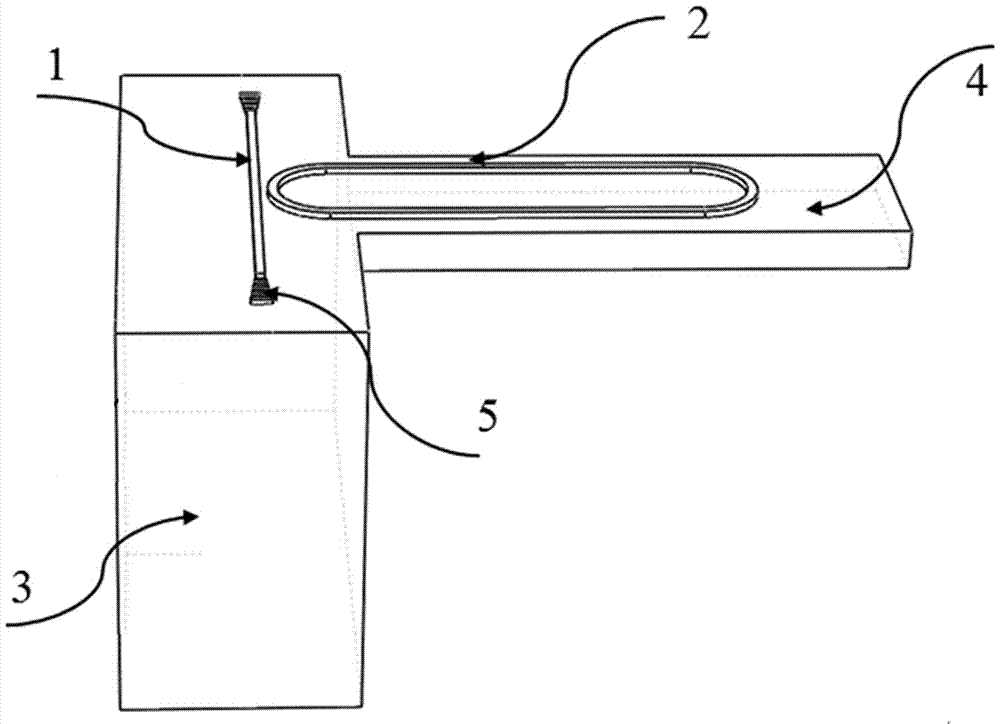

[0023] A MOEMS accelerometer based on a planar annular cavity, including an SOI sheet, the substrate silicon in the SOI sheet is used as a base 3, a cantilever beam 4 is etched on one side of the base 3, and a mutual coupled straight waveguide is etched on the top layer of silicon 1 and a ring-shaped racetrack-shaped micro-ring resonator 2, wherein the micro-ring resonator 2 is located on a cantilever beam 4, and gratings 5 are etched at both the incident end and the outgoing end of the straight waveguide 1.

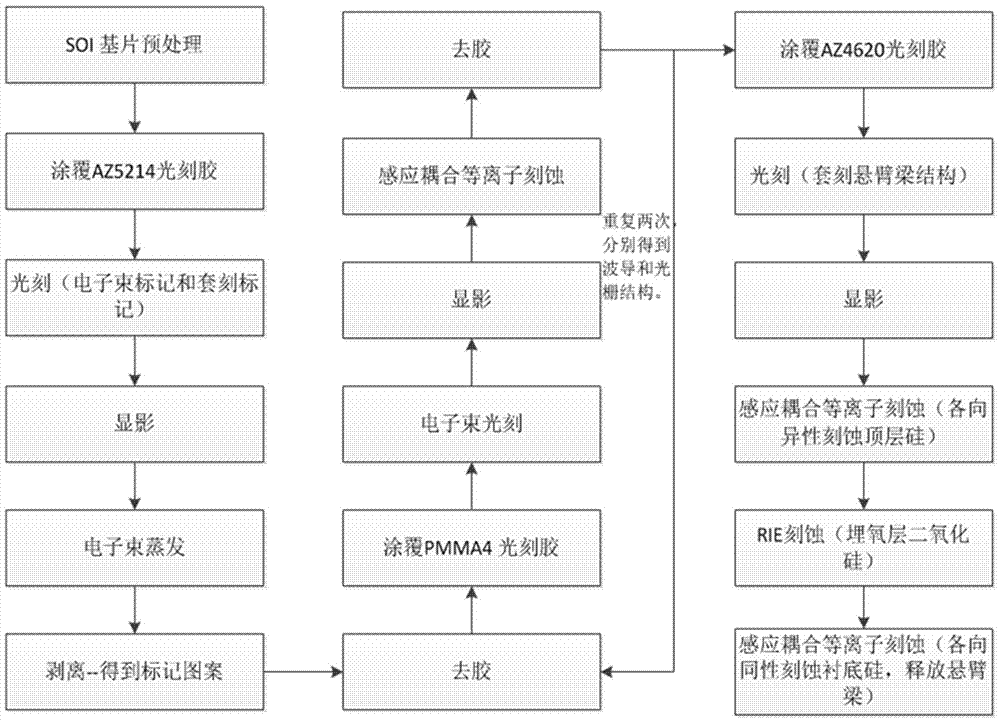

[0024] The above-mentioned manufacturing method based on the MOEMS accelerometer of the planar annular cavity comprises the following steps:

[0025] Step 1: Select the SOI sheet and perform high-temperature pretreatment on the SOI sheet to eliminate the residual stress in the SOI sheet, reduce the structural damage caused by the residual stress, and improve the yield;

[0026] Step 2: Coat AZ5214 photoresist on the pretreated SOI silicon wafer. When coating the photor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com