Low-power-consumption heat insulation and preservation strengthening process of LCD module

A heat insulation and low power consumption technology, which is applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor heat preservation effect, improve heating effect, reduce heating power consumption, and reduce or block heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

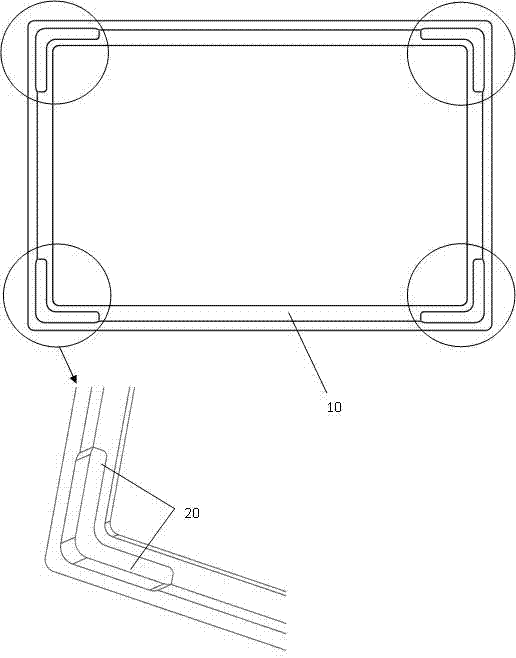

[0021] Such as figure 1 shown.

[0022] A low-power heat insulation and heat preservation reinforcement method for an LCD module. First, a heat preservation groove is processed at each of the four corners of the metal front shell, and the inner surface of the heat preservation groove is frosted to form a frosted surface; the heat preservation groove is 15mm long, 5mm wide, and deep 0.2mm, secondly, prepare an airgel composite thermal insulation felt, the airgel composite thermal insulation blanket is formed by lapping glass fibers with a diameter of 3 μm, and the skeleton gap is evenly filled with airgel particles with a particle size of 100nm. The thermal conductivity of the thermal insulation blanket is 0.024W / m·K; thirdly, the airgel composite thermal insulation blanket is glued to the heat preservation tank by using a thermal insulation coating with hollow glass microspheres as the core.

Embodiment 2

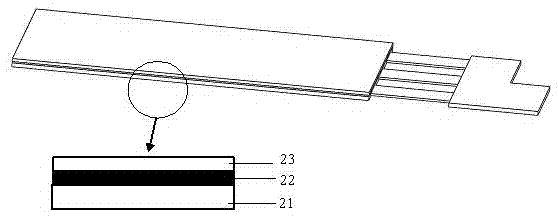

[0024] Such as figure 2 shown.

[0025] A method for reinforcing LCD modules with low power consumption and heat insulation, which is realized by coating a transparent heat insulation and heat preservation optical composite glue 22 with a thickness of 0.2-0.3 mm between a liquid crystal display screen 21 and a glass 23 . The transparent thermal insulation optical composite glue 22 is made of nano SiO 2 Composed of airgel slurry, water-based acrylate resin, dispersant, initiator and other fillers, the mass percentages of each component are: nano-SiO 2 Airgel slurry 15%~25%, water-based acrylate resin 60%~75%, dispersant 2%~5%, initiator 1%~5%, other fillers 1%~3%, the sum of each component 100%; the nano-SiO 2 The airgel slurry mainly includes 60%~80% tetraethyl orthosilicate silica sol, 5%~10% infrared opacifying agent, 5%~20% reinforcing fiber; the infrared opacifying agent is based on alcohol Indium tin oxide ITO nano alcohol paste or ITO and TiO as dispersant 2 Nano-c...

Embodiment 3

[0028] refer to figure 1 , a low-power heat insulation and heat preservation reinforcement method for an LCD module. At first, a heat preservation groove is processed at each of the four corners of the metal front shell, and the inner surface of the heat preservation groove is frosted to form a frosted surface; the length of the heat preservation groove is 15mm, and the width is 5mm. The depth is 0.2mm. Secondly, the airgel composite thermal insulation blanket is prepared. The airgel composite thermal insulation blanket is formed by lapping glass fibers with a diameter of 3 μm. , the thermal conductivity of the thermal insulation blanket is 0.024W / m·K; third, the airgel composite thermal insulation blanket is glued to the heat preservation tank by using the thermal insulation coating with hollow glass microspheres as the core; finally, in A layer of transparent heat-insulating optical composite glue with a thickness of 0.2~0.3mm is coated between the liquid crystal screen and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com