Lithium ion battery negative electrode active material and preparation thereof, lithium ion battery negative electrode material, lithium ion battery negative electrode and lithium ion battery

A negative electrode active material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of rate performance and cycle stability decline, low initial efficiency of lithium-ion batteries, and reduced capacity of lithium-ion batteries. Achieve the effects of strong cycle stability, high initial efficiency, and high rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] According to the second aspect of the present invention, the present invention provides a kind of preparation method of described lithium-ion battery negative pole active material, and this method comprises the steps:

[0035] (1) contacting a mixed solution containing a water-soluble tin salt, a water-soluble cobalt salt and a carbon source material with an alkaline substance for a contact reaction, and obtaining a solid powder A from the obtained contact mixture;

[0036] Wherein, the carbon source material is selected from at least one of natural spherical graphite, soft carbon, and hard carbon; relative to 100 parts by weight of the carbon source material, the amount of the water-soluble tin salt is the weight of the tin element The sum of the parts by weight of parts and the consumption of water-soluble cobalt salt is 5-20 parts by weight in terms of cobalt element;

[0037] (2) performing reduction treatment on the solid powder A obtained in step (1) to obtain sol...

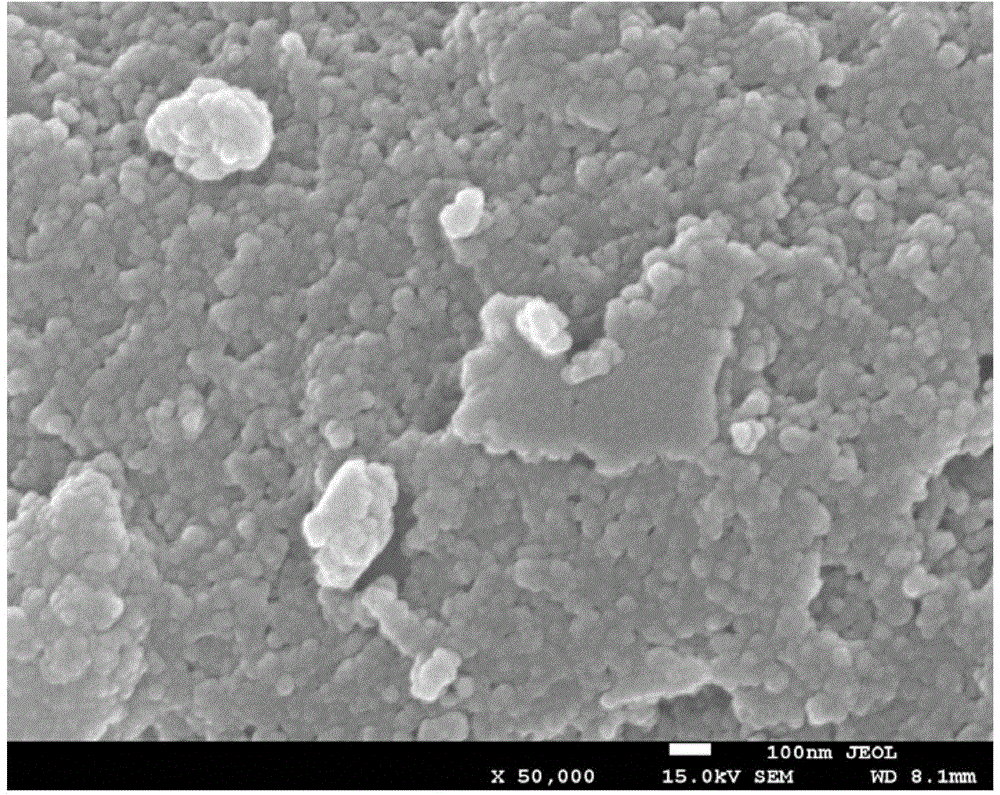

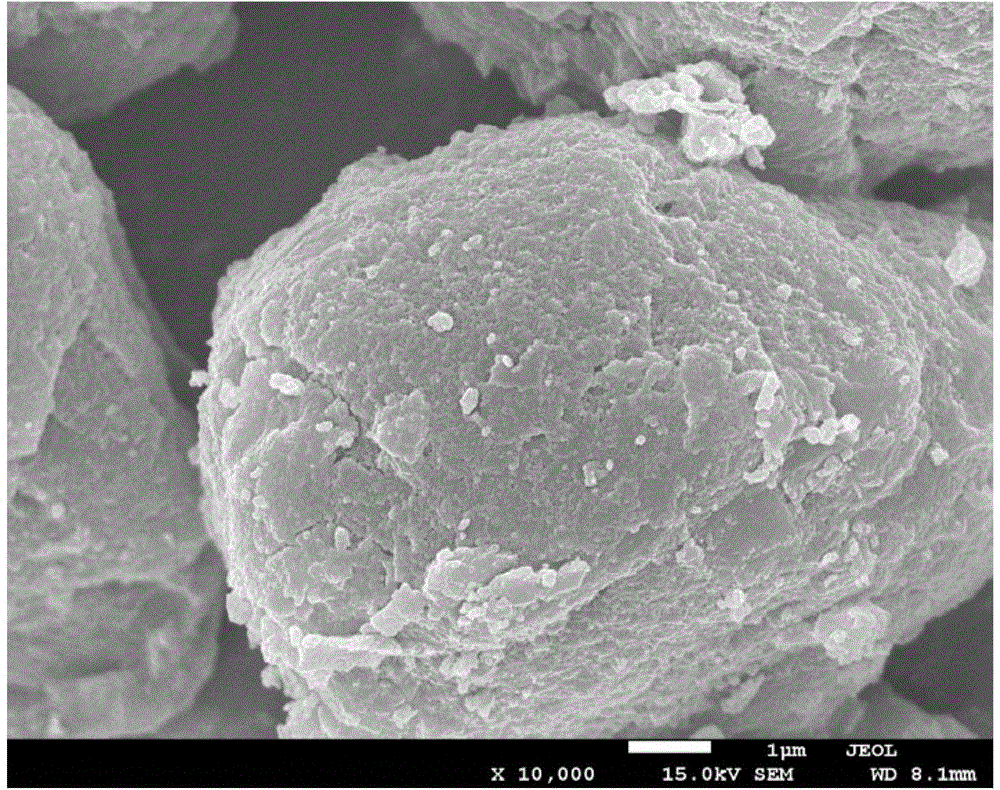

Embodiment 1

[0075] This example is used to illustrate the lithium ion battery negative electrode active material provided by the present invention and its preparation method, as well as the lithium ion battery containing the lithium ion battery negative electrode active material and its preparation method.

[0076] (1) Mix stannous sulfate, cobalt chloride hexahydrate, polyvinylpyrrolidone (purchased from Sinopharm Chemical Reagent Co., Ltd. with the brand name K-30) and natural spherical graphite (purchased from Qingdao Taihelong New Energy Materials Co., Ltd. A10 commodity) into deionized water, stirring constantly to mix evenly. Add the mixed solution into a stainless steel reaction kettle, heat it in a circulating water bath at 80°C, and stir at a speed of 180r / min for 0.5h;

[0077] Ammonium bicarbonate is made into the solution of 0.2g / mL with deionized water, then use metering pump (purchased from IWAKIPUMPS company trade mark to be the commodity of EHN_R type) slowly drop in the s...

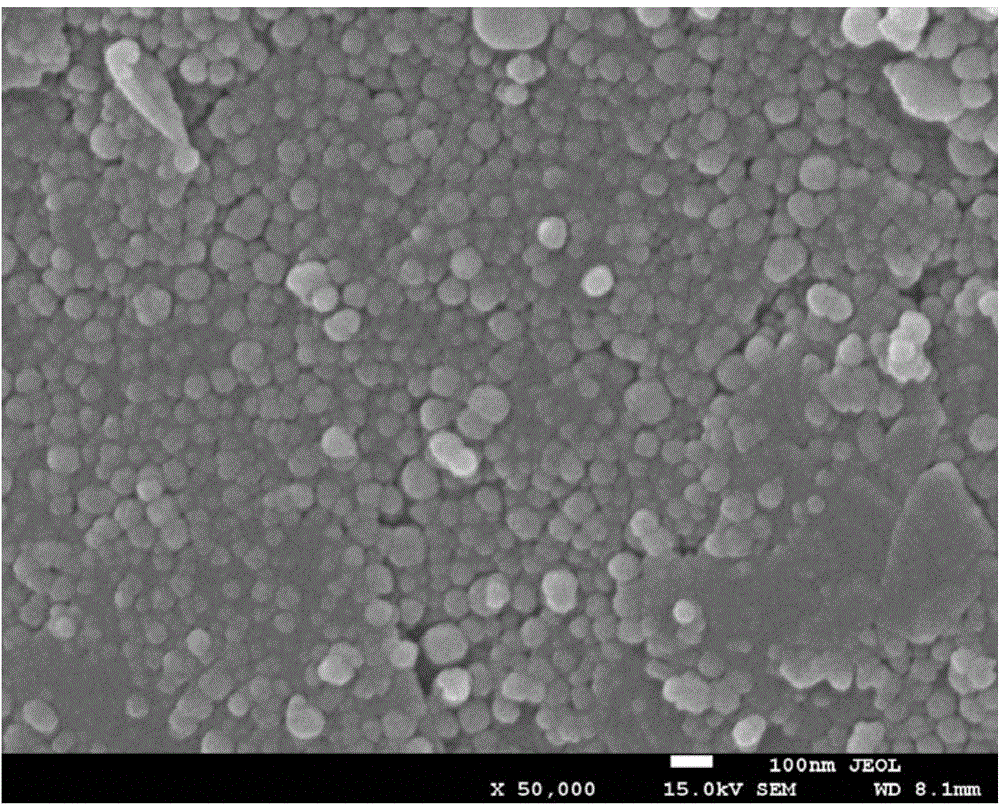

Embodiment 2

[0092] Except the operating parameters in Table 1 and the following parameters, the operating method is the same as in Example 1.

[0093] In step (1), the composition of the carbon source material used is: 90% by weight of natural spherical graphite and 10% by weight of soft carbon. The alkaline substance used is sodium bicarbonate. The ratio of the weight of tin salt calculated as tin element to the weight of cobalt salt calculated as cobalt element is 1:0.5.

[0094] The obtained lithium-ion battery is denoted as S2. The performance parameters of S2 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com