A kind of preparation method of three-layer structure small diameter vascular stent

A vascular stent and three-layer structure technology, applied in the biomedical field, can solve the problems of inability to meet the needs of small-diameter vascular stents, vascular intimal hyperplasia, easy formation of thrombus, etc., and achieve good cell compatibility and biodegradability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

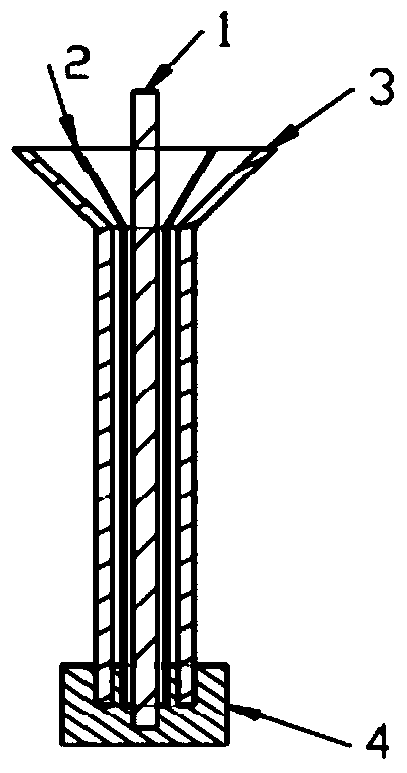

[0044] The present invention uses figure 1 The mold shown is used to prepare vascular stents. The mold includes a first hollow aluminum tube, a second hollow aluminum tube, a third hollow aluminum tube and a base. The first hollow aluminum tube is located in the second hollow aluminum tube, and the second hollow aluminum tube is located in the third hollow aluminum tube. The first hollow aluminum tube, the second hollow aluminum tube and the third hollow aluminum tube are arranged concentrically on the base, and are selected and installed on the base according to requirements.

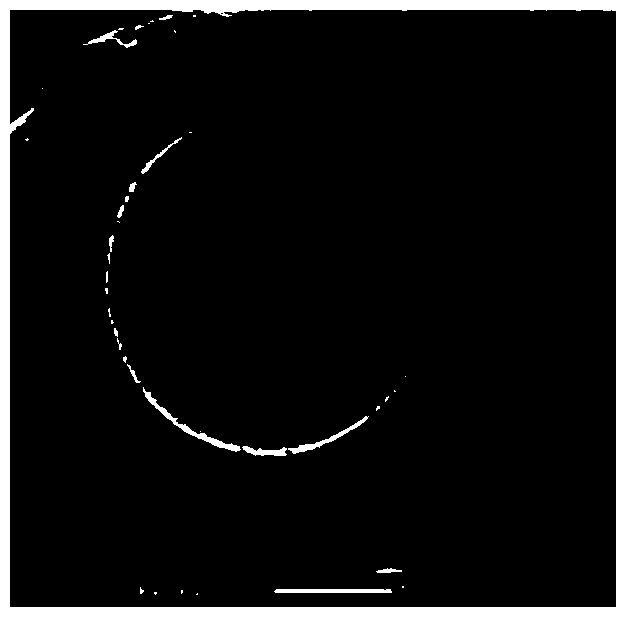

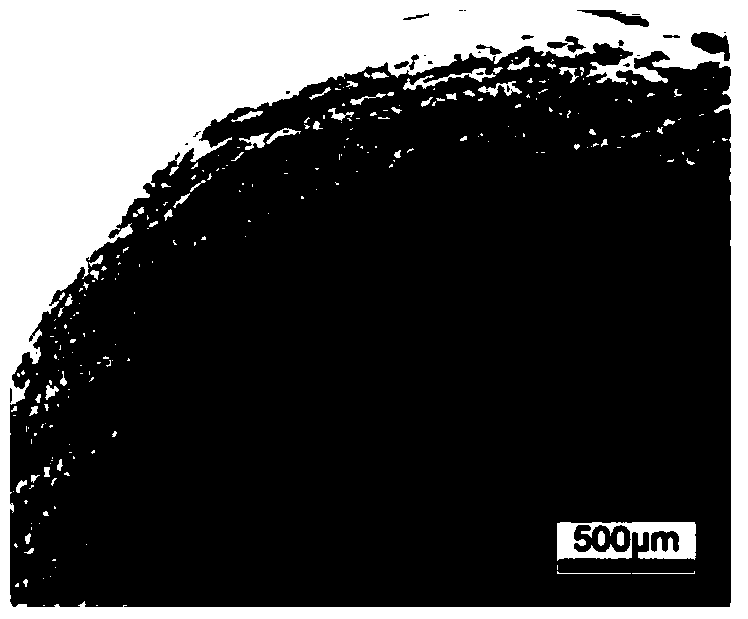

[0045] The blood vessel stent prepared by the invention has a thickness of 0.5-1 mm and a length of 5-8 mm. Vascular stent simulates and bionics the vascular structure, including inner layer, middle layer, and outer layer; the inner layer is a tubular scaffold composed of fibers prepared by electrospinning, and the middle layer is a tubular scaffold composed of porous structures prepared by freeze-dr...

Embodiment 2

[0057] The present invention specifically comprises the following steps:

[0058] (1) Preparation of inner layer:

[0059] a2. adding thermoplastic polyurethane to dimethylformamide and stirring magnetically at 70° C. for 8 hours to prepare a thermoplastic polyurethane spinning solution with a concentration of 11% by mass;

[0060] b2. Install the thermoplastic polyurethane spinning solution prepared in step a2 on an electrospinning device for spinning, and use the first rotating hollow aluminum tube to collect fibers to prepare a tubular support. The spinning voltage is 15kV and the receiving distance is 16cm. , the flow rate is 0.5ml / h; an inner layer is formed on the outer wall of the first hollow aluminum tube;

[0061] (2) The preparation of the outer layer adopts freeze-drying method:

[0062] c2. forming the first hollow aluminum tube, the second hollow aluminum tube, and the third hollow aluminum tube with an inner layer obtained in step b2 into a concentric hollow c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com