A preparation method of mesoporous carbon fiber material assembled with hollow nanocarbon spheres

A technology of hollow nano and fiber materials, applied in the direction of nano carbon, nano technology, nano technology, etc., can solve the problems of single structure and morphology of mesoporous carbon materials, increased production costs, etc., achieve good water dispersion, overcome light specific gravity, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

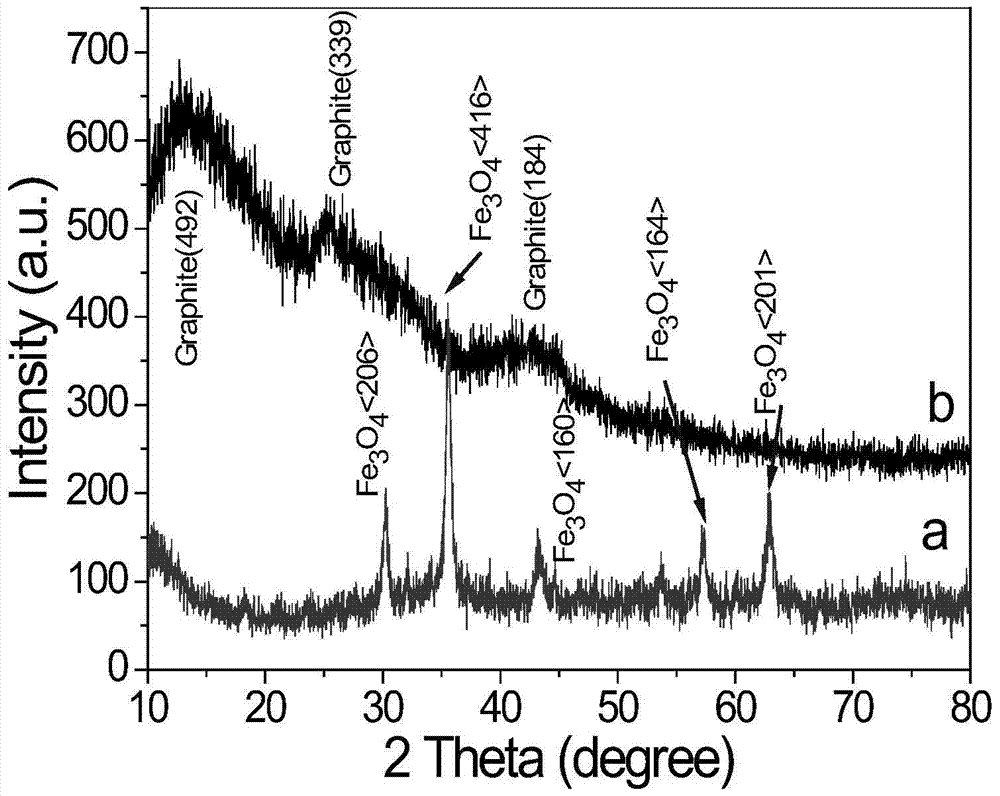

Embodiment 1

[0030] (1) 13.9g of ferrous sulfate was fully dissolved in a mixed solvent (500mL) of isopropanol and water, wherein the volume ratio of isopropanol to water was 0.2:1; 4.8g of nitrilotriacetic acid was dispersed in the above solution. The mixture was left to stand at 180°C for 24 hours, cooled, and then the feed liquid was filtered to remove the solvent, the filtrate was recovered for use, and the filter cake was air-dried at 100°C for 5 hours.

[0031] (2) Place the dried filter cake obtained in step 1 into a crucible and seal it, then heat up to 500°C in a muffle furnace at a rate of 2°C / min and roast for 4h, then cool to room temperature.

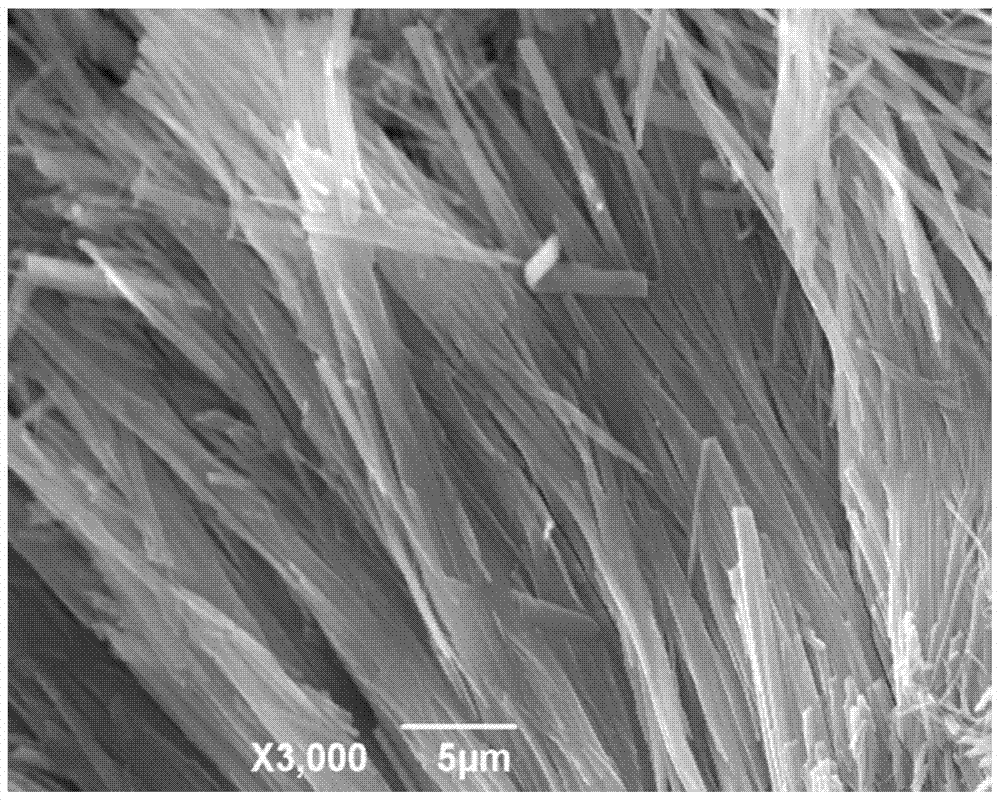

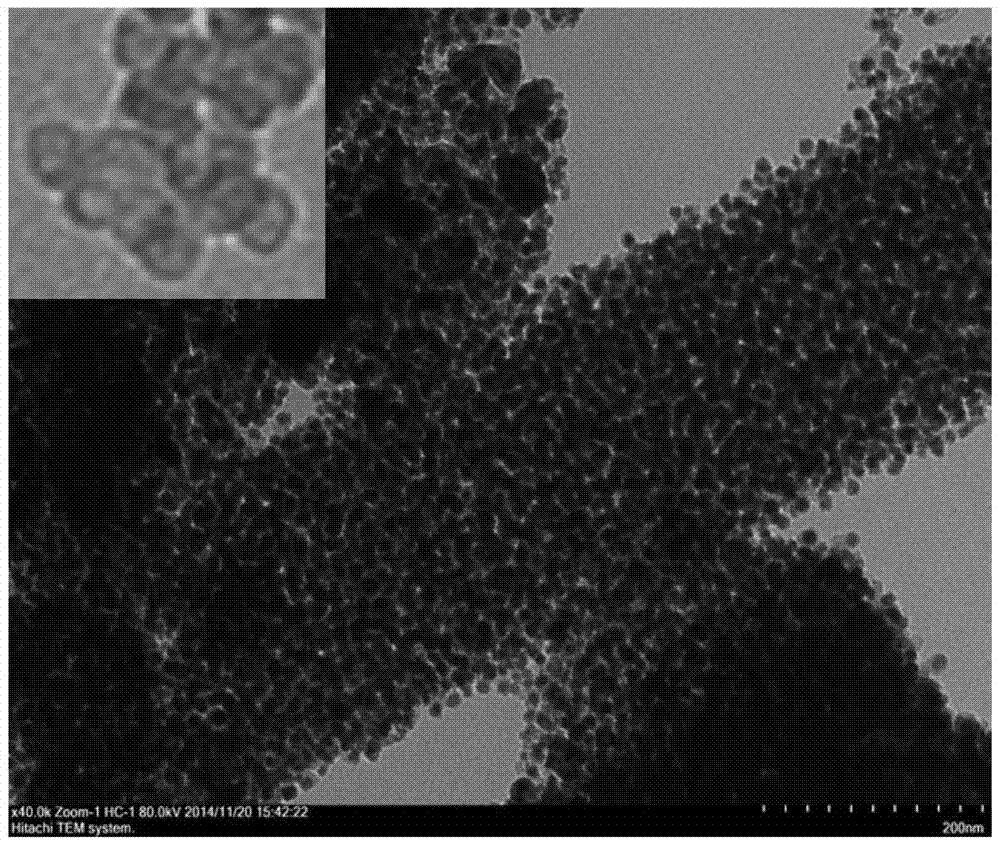

[0032] (3) Add 10 g of the roasted product of step (2) into 200 mL, 4 mol / L hydrochloric acid solution and let it stand for 10 h, filter, wash with 2 mol / L sodium hydroxide solution, and then wash with distilled water until the filtrate is neutral, which is the same as 100 °C Blow drying for 5h. That is, nano hollow carbon spheres asse...

Embodiment 2

[0035] (1) 13.1g of nickel sulfate was fully dissolved in a mixed solvent (500mL) of isopropanol and water, wherein the volume ratio of isopropanol to water was 0:1; 3.3g of nitrilotriacetic acid was dispersed in the above solution. The mixture was left to stand at 220°C for 12 hours, cooled, and then the feed liquid was filtered to remove the solvent, the filtrate was recovered for use, and the filter cake was air-dried at 100°C for 5 hours.

[0036] (2) Place the dried filter cake obtained in step 1 into a crucible and seal it, then heat up to 400°C for 6 hours in a muffle furnace at a rate of 1°C / min, and then cool to room temperature.

[0037] (3) Add 8 g of the roasted product of step (2) into 600 mL, 2 mol / L sulfuric acid solution and let it stand for 6 hours, filter, wash with 1 mol / L sodium hydroxide solution, and then wash with distilled water until the filtrate is neutral, which is different from 100 °C Blow drying for 5h. That is, nano hollow carbon spheres assembl...

Embodiment 3

[0040](1) 13.9g of ferrous sulfate was fully dissolved in a mixed solvent (500mL) of isopropanol and water, wherein the volume ratio of isopropanol to water was 0.5:1; 3.3g of nitrilotriacetic acid was dispersed in the above solution. The mixture was left to stand at 200°C for 18 hours, cooled, and then the feed liquid was filtered to remove the solvent, the filtrate was recovered for use, and the filter cake was air-dried at 100°C for 5 hours.

[0041] (2) Place the dried filter cake obtained in step 1 into a crucible and seal it, then heat up to 600°C in a muffle furnace at a rate of 5°C / min and roast for 3h, then cool to room temperature.

[0042] (3) Add 6 g of the roasted product of step (2) into 400 mL, 3 mol / L nitric acid solution and let it stand for 8 hours, filter, wash with 0.5 mol / L sodium hydroxide solution, and then wash with distilled water until the filtrate is neutral. ℃ blast drying for 5h. That is, nano hollow carbon spheres assembled mesoporous carbon fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com