Martensite phase transformation enhanced type double-phase stainless steel and method for making seamless steel pipe from same

A technology for duplex stainless steel and martensitic transformation, which is applied to high toughness martensitic transformation enhanced duplex stainless steel and its manufacturing of seamless steel pipes, high strength fields, and can solve the problem of high production cost, prolonged production cycle, oil , the increase of gas production cost and pressure, etc., to achieve the effect of good anti-CO2 uniform corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

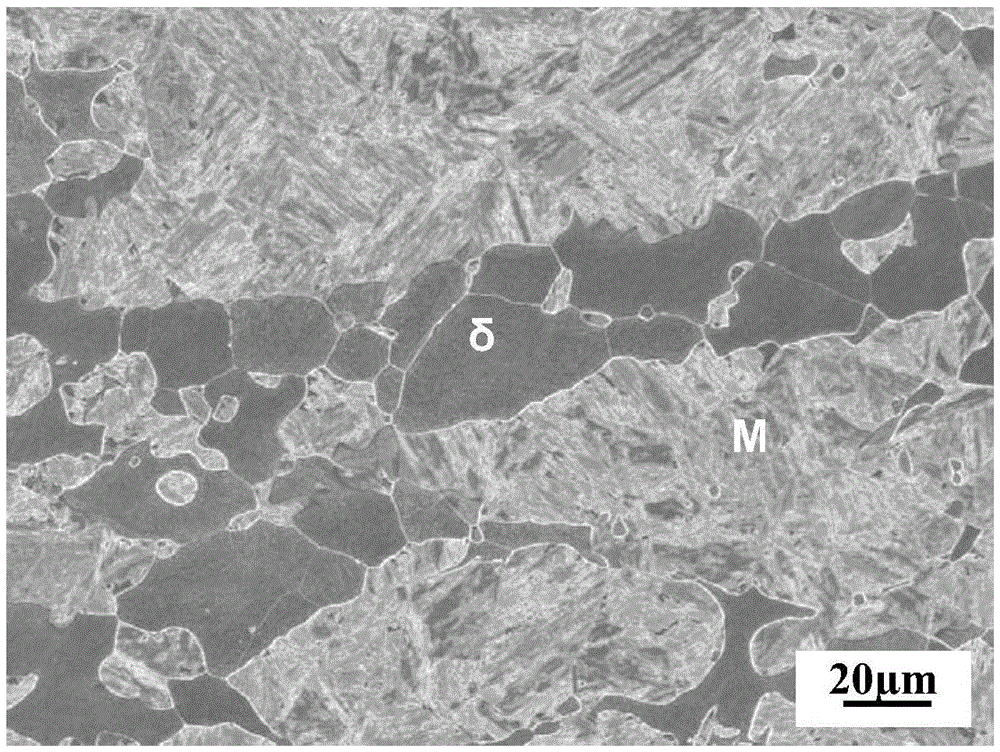

Image

Examples

Embodiment

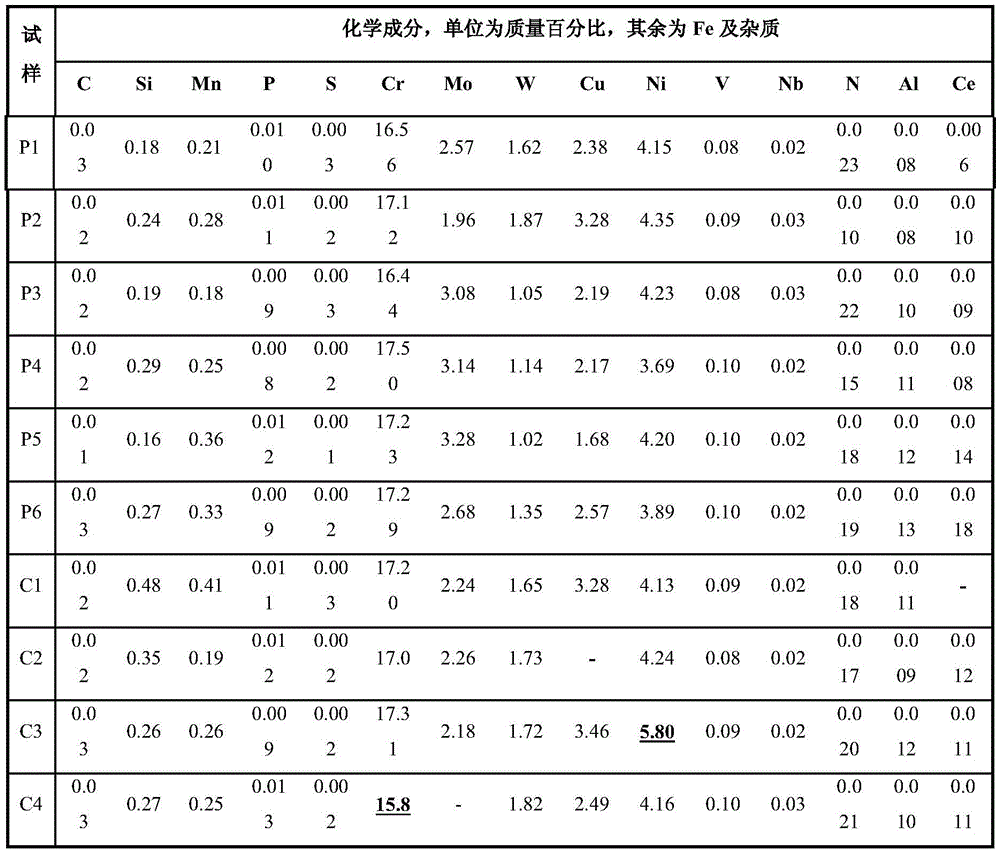

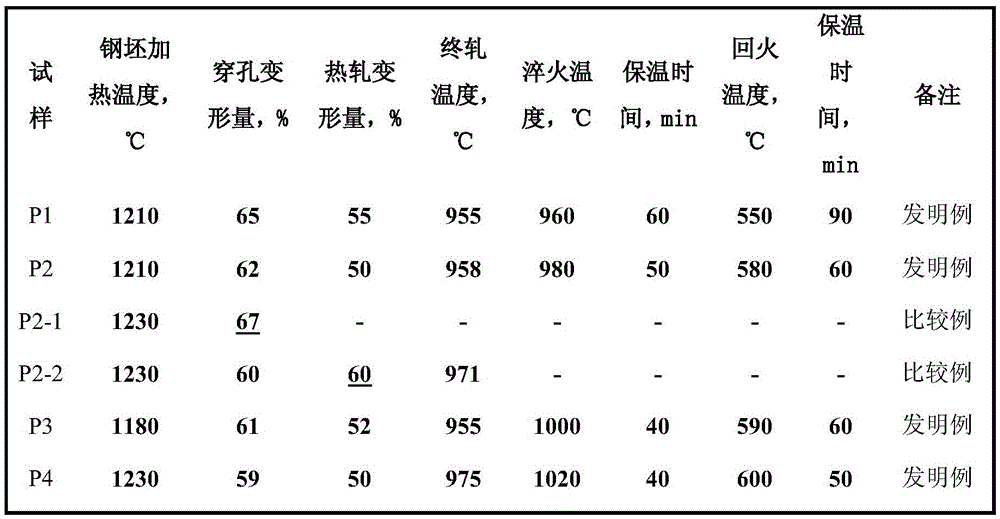

[0056] The chemical composition (wt%) of each embodiment and comparative example has been listed in table 1, and wherein P1-P6 is invention example, and C1-C4 is comparative example, after the composition shown in table 1 is smelted, forges round steel billet, The diameter of the steel billet is 230±10mm, and then the surface scale is removed by machining, and the diameter becomes 210±10mm. Seam steel pipe, the outer diameter of the steel pipe is 140±5mm, and the wall thickness is 10±2mm. After the steel pipe is cooled to room temperature, heat treatment is carried out to adjust the strength and the ratio of the two phases. The specific process is shown in Table 2.

[0057] It can be seen from Table 2 that during the piercing and rolling process of seamless steel pipes, the heating temperature, piercing and rolling deformation must be strictly controlled, otherwise the steel pipes are prone to various defects. Wherein the P2-1 and P2-2 samples are due to the excessive thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com