Low-temperature improved ternary battery and preparation method thereof

A ternary battery, low temperature technology, applied in the direction of battery electrodes, secondary batteries, battery components, etc., can solve the problems that affect the popularization and application of lithium batteries, serious internal polarization, low battery discharge rate, etc., to improve low temperature discharge ability, reduce polarization, and the effect of reasonable coating thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

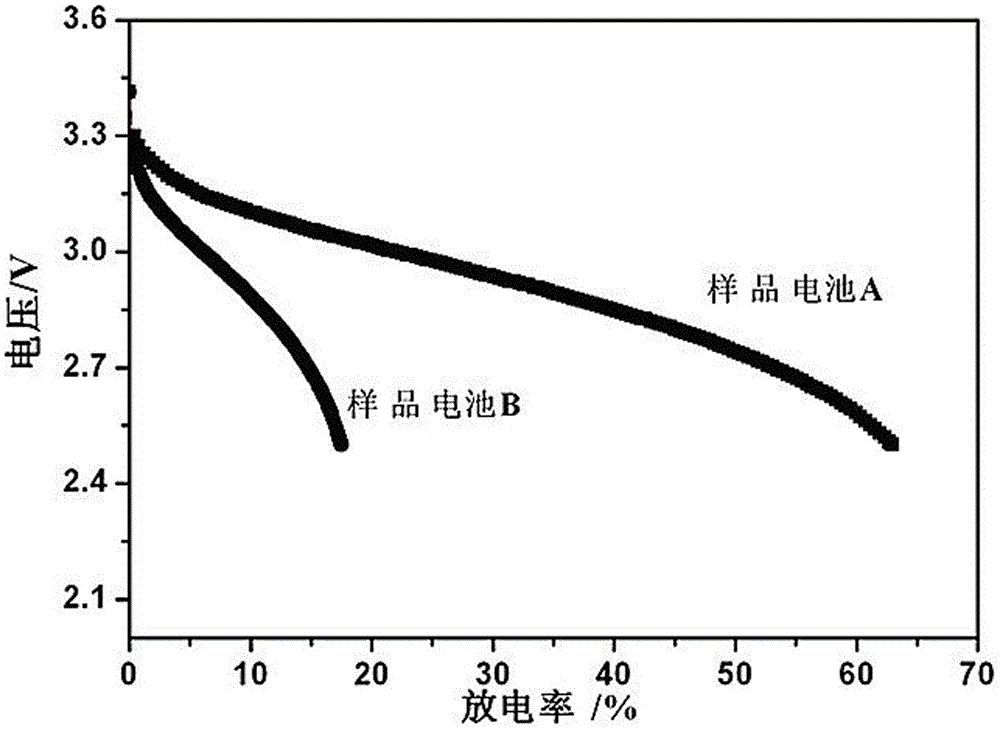

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Production of positive electrode sheet: Weigh 88g nickel-cobalt lithium manganese oxide, 2gSuperC65, 2gKS-6, 2gVGCF, 2gCNTs and 4gPVDF in sequence, add NMP and stir for 2h to obtain a uniform and stable positive electrode slurry; The final positive electrode sheet is prepared by the steps of rolling, cutting and sheeting; wherein, the coating thickness of the positive electrode slurry is controlled to be 180um, and the positive electrode tab is located in the middle of the electrode sheet;

[0023] (2) Production of negative electrode sheet: Weigh 90g graphite, 2gSuperC65, 2gCNTs, 2gVGCF and 4gCMC in sequence, add water and stir for 2h to obtain a uniform and stable negative electrode slurry; The final negative electrode sheet is prepared by steps such as the following steps; wherein, the coating thickness of the negative electrode slurry is controlled to be 160um, and the two tab positions of the negative electrode are distributed at both ends of the electrode sheet...

Embodiment 2

[0028] (1) Production of positive electrode sheet: Weigh 94g nickel-cobalt lithium manganese oxide, 2.285g SuperC65, 1.142gKS-6, 2.285gVGCF, 2.285gCNTs and 2gPVDF in sequence, add NMP and stir for 2 hours to obtain a uniform and stable positive electrode slurry; Cloth, drying, roll-to-roll, slitting, and sheet-making steps to prepare the final positive electrode sheet; wherein, the coating thickness of the positive electrode slurry is controlled to be 120um, and the positive electrode lug is located in the middle of the electrode sheet;

[0029] (2) Production of negative electrode sheet: Weigh 97g graphite, 0.67gSuperC65, 0.67gCNTs, 0.67gVGCF and 1gCMC in sequence, add water and stir for 2 hours to obtain a uniform and stable negative electrode slurry; Steps such as cutting and sheeting are used to prepare the final negative electrode sheet; wherein, the coating thickness of the negative electrode slurry is controlled to be 100um, and the two tab positions of the negative elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com