Preparation method and use of local flavor antimicrobial microemulsion

A microemulsion and flavor technology, applied in the application, food preservation, fruit and vegetable preservation and other directions, can solve the problems of low effective components, difficult preservation, difficult transportation and preservation problems, etc., and achieves simple process steps, good stability, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

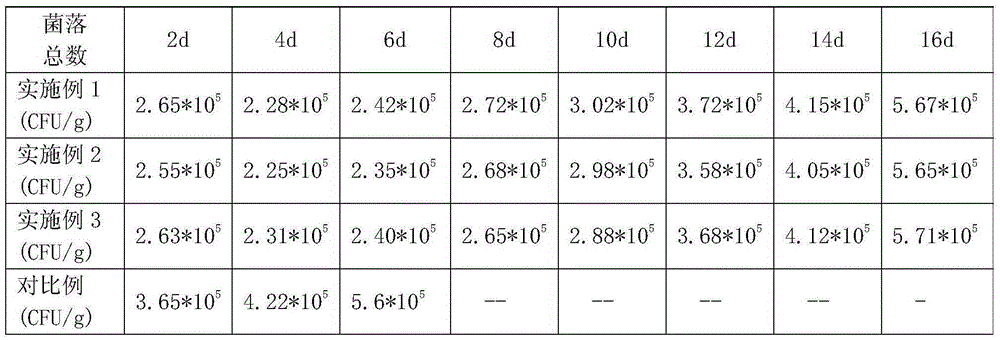

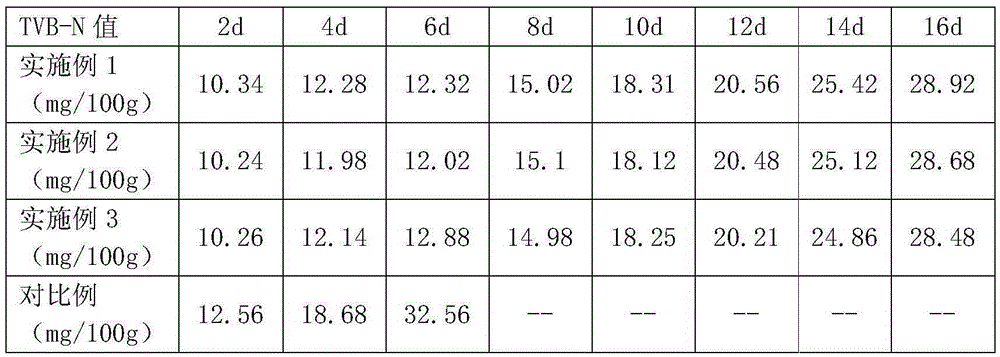

Examples

Embodiment 1

[0020] (1) Mince ginger and mix it with food-grade absolute ethanol at a mass ratio of 1:1, shake and extract on a constant temperature shaker at 37±1°C for 4 hours, and then filter with suction to obtain an alcohol-soluble extract, which is removed by rotary vacuum evaporation The extractant ethanol is used to obtain ginger oil; the garlic cloves are chopped and mixed with food-grade absolute ethanol at a mass ratio of 1:1, extracted for 4 hours on a constant temperature shaker at 37±1°C, and then filtered with suction to obtain alcohol-soluble extract liquid, rotary vacuum evaporation to remove the extractant ethanol, to obtain garlic oil;

[0021] (2) According to 40% mature vinegar, 0.5% ginger oil, 0.5% garlic oil, 1% polyglycerol monolaurate, 5% food grade absolute ethanol, 0.5% sodium caseinate, 0.01% glucose oxidase, 1% Glucose, 0.01% nano-silica, the balance is the mass percentage of water, proportioning and weighing each component, stand-by;

[0022] (3) After mixin...

Embodiment 2

[0027] (1) Mince ginger and mix it with food-grade absolute ethanol at a mass ratio of 1:1, shake and extract on a constant temperature shaker at 37±1°C for 4.5 hours, then filter with suction to obtain an alcohol-soluble extract, and evaporate in a rotary vacuum Remove the extractant ethanol to obtain ginger oil; chop the garlic cloves and mix them with food-grade anhydrous ethanol at a mass ratio of 1:1, shake and extract on a constant temperature shaker at 37±1°C for 4.5 hours, and then filter with suction to obtain alcohol The soluble extract was removed by rotary vacuum evaporation to remove the extractant ethanol to obtain garlic oil;

[0028] (2) According to 45% mature vinegar, 0.8% ginger oil, 0.7% garlic oil, 2% polyglycerol monolaurate, 7% food grade absolute ethanol, 0.6% sodium caseinate, 0.02% glucose oxidase, 2% Glucose, 0.02% nano-silica, the balance is the mass percentage of water, proportioning and weighing each component, stand-by;

[0029] (3) After mixing...

Embodiment 3

[0034] (1) Mince ginger and mix it with food-grade absolute ethanol at a mass ratio of 1:1, shake and extract on a constant temperature shaker at 37±1°C for 5 hours, and then filter with suction to obtain an alcohol-soluble extract, which is removed by rotary vacuum evaporation The extractant ethanol is used to obtain ginger oil; the garlic cloves are chopped and mixed with food-grade absolute ethanol at a mass ratio of 1:1, extracted by shaking on a constant temperature shaker at 37±1°C for 5 hours, and then filtered with suction to obtain alcohol-soluble extracts liquid, rotary vacuum evaporation to remove the extractant ethanol, to obtain garlic oil;

[0035] (2) According to 50% mature vinegar, 1% ginger oil, 1% garlic oil, 3% polyglycerol monolaurate, 10% food grade absolute ethanol, 1% sodium caseinate, 0.03% glucose oxidase, 3% Glucose, 0.03% nano-silicon dioxide, and the balance is the mass percentage of water. Weigh each component and set aside;

[0036] (3) After mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com