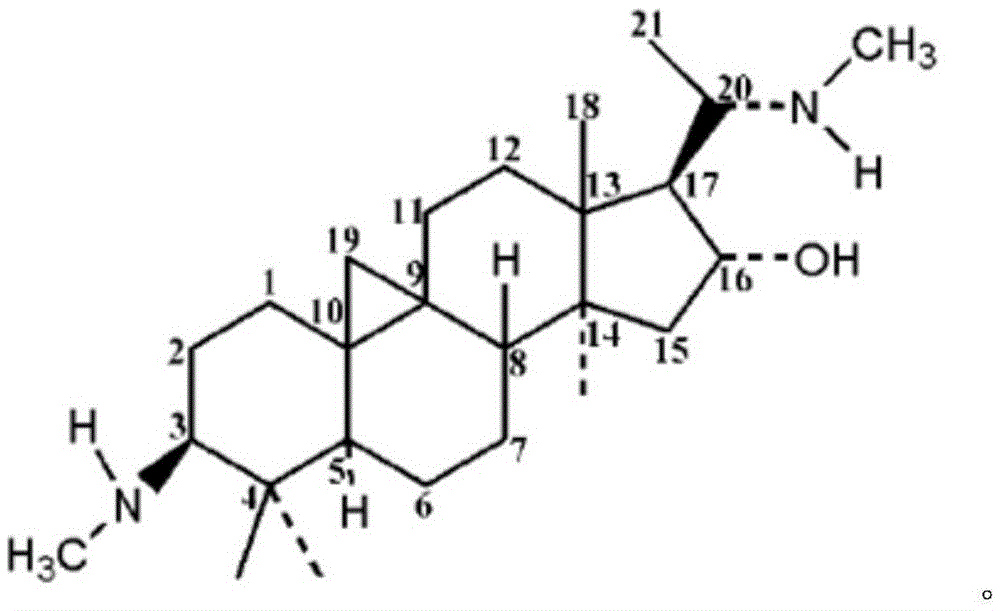

Huangyangning dispersible tablets and preparation method thereof

A technology of dispersible tablets and Buyangning, which is applied to medical preparations with no active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0135] 1) Use a supercritical reaction device to micronize Cyclovitamin D, wherein the machine parameters are: pre-expansion pressure 25MPA, pre-expansion temperature 320K, nozzle diameter 0.1mm, and obtain micronized Cyclovitamin D;

[0136] 2) Put 2g of micronized cyclovirbuxine D and 3.7g of soybean lecithin in a conical flask, use 200ml of ethanol as the reaction solvent, heat and stir to 55°C, and the rotation speed is 500r / min, react for 1h, take the reaction solution in The reaction solvent was removed by rotary evaporation at 60°C, and the solid was vacuum-dried for 1 hour to obtain the phospholipid complex;

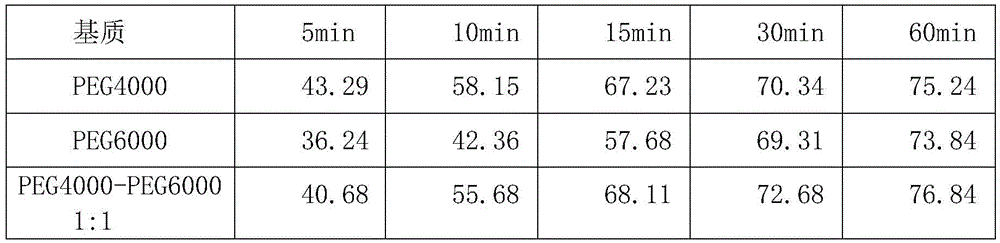

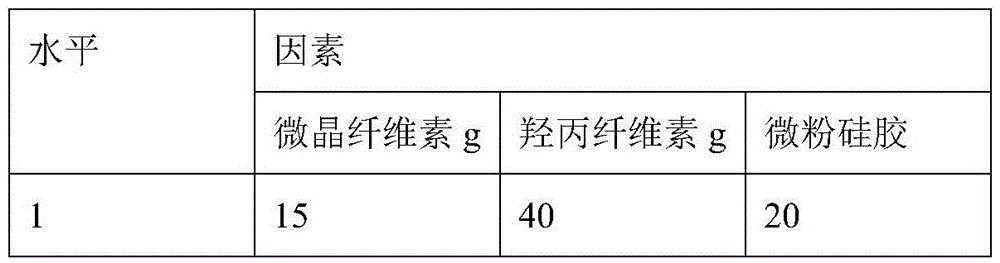

[0137] 3) Mix the phospholipid complex and PEG4000 according to the ratio of 1:2.5, after fully grinding evenly, spray a small amount of absolute ethanol, continue to grind into a uniform thick paste, dry in vacuum at 60°C for 3h, transfer to -20°C for curing for 24h , quickly pulverized after taking out, and passed through an 80-mesh sieve to obtain a phospholip...

Embodiment 2

[0140] 1) Use a supercritical reaction device to micronize Cycloviral Buxillus D, wherein the machine parameters are: pre-expansion pressure 25MPA, pre-expansion temperature 370K, nozzle diameter 0.2mm, and obtain micronized Cycloviral Buxus D;

[0141] 2) Put 2g of micronized cyclovirbuxine D and 3.7g of soybean lecithin in a conical flask, use 200ml of ethanol as the reaction solvent, heat and stir to 55°C, and the rotation speed is 500r / min, react for 1h, take the reaction solution in The reaction solvent was removed by rotary evaporation at 60°C, and the solid was vacuum-dried for 1 hour to obtain the phospholipid complex;

[0142] 3) Mix the phospholipid complex and PEG4000 at a ratio of 1:2, grind them evenly, spray a small amount of absolute ethanol, continue to grind into a uniform thick paste, dry in vacuum at 60°C for 3 hours, transfer to -20°C and solidify for 24 hours , quickly pulverized after taking out, and passed through an 80-mesh sieve to obtain a phospholipi...

Embodiment 3

[0145] 1) Use a supercritical reaction device to micronize Cyclovitamin D, wherein the machine parameters are: pre-expansion pressure 35MPA, pre-expansion temperature 420K, nozzle diameter 0.5mm, and obtain micronized Cyclovitamin D;

[0146] 2) Put 2g of micronized cyclovirbuxine D and 3.7g of soybean lecithin in a conical flask, use 200ml of ethanol as the reaction solvent, heat and stir to 55°C, and the rotation speed is 500r / min, react for 1h, take the reaction solution in The reaction solvent was removed by rotary evaporation at 60°C, and the solid was vacuum-dried for 1 hour to obtain the phospholipid complex;

[0147] 3) Mix the phospholipid complex and PEG4000 at a ratio of 1:3. After fully grinding evenly, spray a small amount of absolute ethanol and continue grinding to form a uniform thick paste. Vacuum dry at 60°C for 3h, transfer to -20°C and solidify for 24h , quickly pulverized after taking out, and passed through an 80-mesh sieve to obtain a phospholipid comple...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com