Device and method for removing deteriorated seeds with liquid specific gravity method

A specific gravity method and seed technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of ineffective removal of corn seeds, low separation accuracy, and unsatisfactory seed removal effect, so as to slow down the aging of seeds. and chilling injury, long storage time, and the effect of improving seed germination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

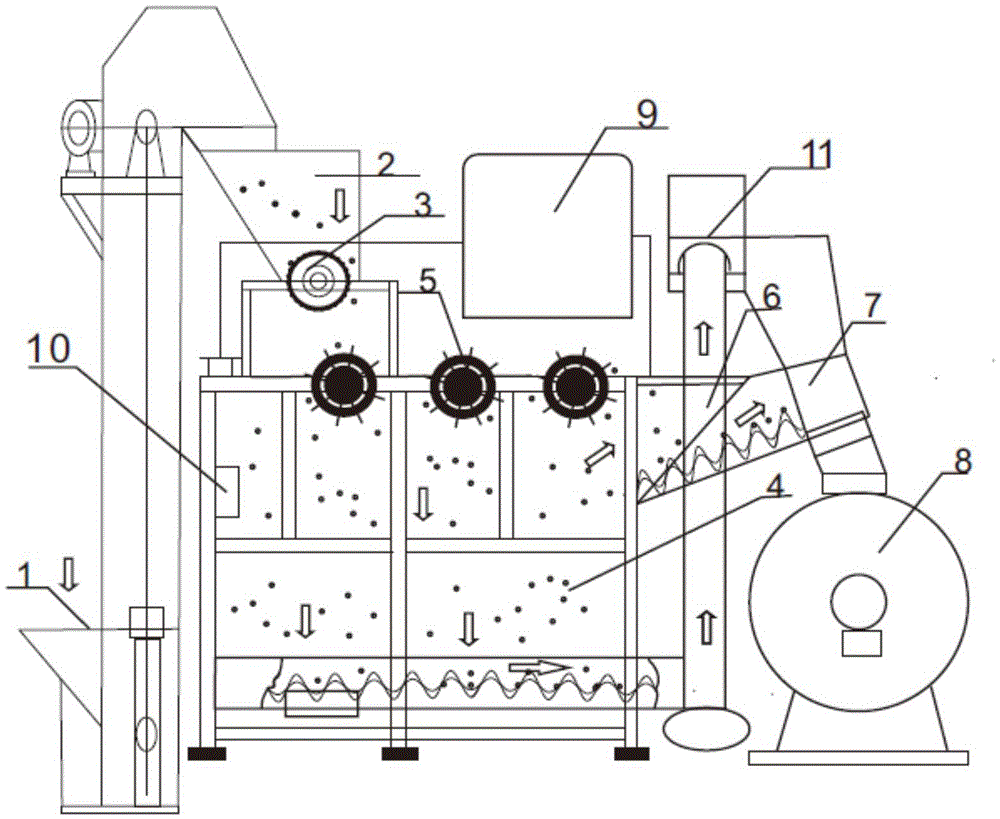

[0029] A device for removing deteriorating seeds by liquid specific gravity method, comprising a feeding mechanism, a discharging mechanism, a special mechanism 10, a forced sinking mechanism 5, a seed selection tank 4, a specific gravity liquid container 9 and an automatic drying centrifuge 8, and the feeding mechanism And discharging mechanism are positioned at the two ends of seed selection groove 4 respectively.

[0030] Preferably, the feeding mechanism includes a bucket elevator 1 , a buffer bucket 2 and a feeder 3 .

[0031] Preferably, the discharge mechanism includes a buffer bin 6, a top screw conveyor 7 and a bottom screw conveyor 11; the top screw conveyor 7 is located above the seed selection tank; the bottom screw conveyor 11 is located in the seed selection tank 4 below.

[0032] Preferably, the seed selection slot 4 is rectangular.

[0033] When working, the seeds to be selected are fed into the buffer bin 2 through the bucket elevator 1, enter the seed selec...

Embodiment 2

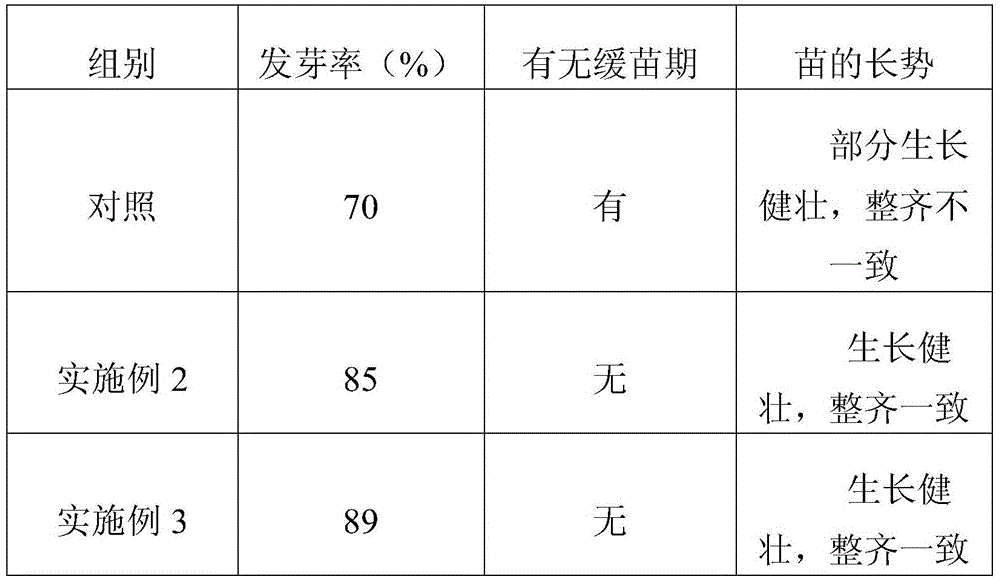

[0035] A method for liquid specific gravity method to remove deteriorated seeds, comprising the following steps:

[0036] (1) Preparation of liquid ammonium sulfate specific gravity solution: in the specific gravity liquid container, medium ammonium sulfate is dissolved in water, stirred until fully dissolved, to obtain specific gravity solution; the mass ratio of ammonium sulfate and water is 0.1:1; described specific gravity The density of the solution is 1.05g / cm 3 ;

[0037] (2) The specific gravity solution obtained is added in the seed selection tank;

[0038] (3) Seed selection: The rice seeds to be selected are fed into the buffer hopper through the elevator, and enter the seed selection tank through the feeder, and the specific gravity liquid container uses a special mechanism to automatically control the liquid level and concentration to replenish the solvent for the seed selection tank; Under the action of the buoyancy of the solution, the forced sinking mechanism...

Embodiment 3

[0041] A method for liquid specific gravity method to remove deteriorated seeds, comprising the following steps:

[0042] (1) Preparation of liquid calcium chloride specific gravity solution: in the specific gravity liquid container, the medium calcium chloride is dissolved in water, stirred until fully dissolved, to obtain specific gravity solution; the mass ratio of calcium chloride and water is 0.36:1; The density of the specific gravity solution mentioned above is 1.27g / cm 3 ;

[0043] (2) The specific gravity solution obtained is added in the seed selection tank;

[0044] (3) Seed selection: The corn seeds to be selected are fed into the buffer hopper through the elevator, and enter the seed selection tank through the feeder, and the specific gravity liquid container uses a special mechanism to automatically control the liquid level and concentration to replenish the solvent for the seed selection tank; Under the action of the buoyancy of the solution, the forced sinkin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com