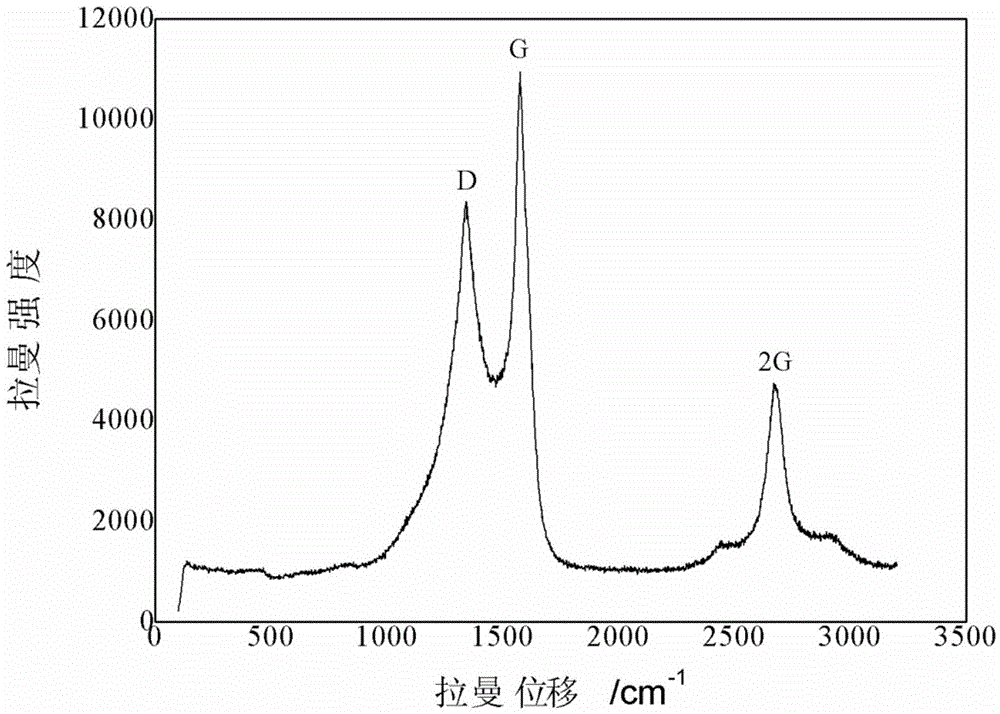

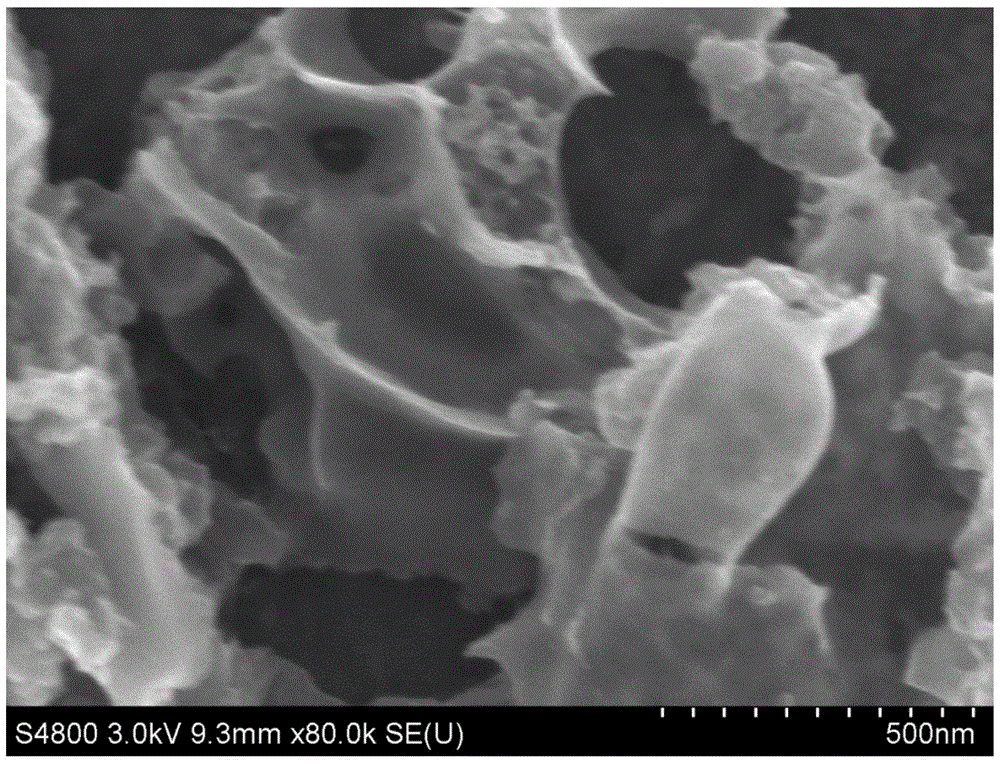

Method for preparing three-dimensional graphene by adopting ethyl cellulose as raw material

A technology of ethyl cellulose and graphene, applied in the field of graphene, can solve problems such as unfavorable large-scale production, high production cost, complicated process, etc., and achieve the effects of strong feasibility, easy cost, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of method that adopts ethyl cellulose to prepare three-dimensional graphene as raw material, comprises the following steps:

[0030] 1) Dissolve analytically pure ethylcellulose and NaOH in a molar ratio of 1:1 in an appropriate amount of ethanol (the mass ratio of ethanol:ethylcellulose and NaOH mixture is 20:1) to prepare a sol;

[0031] 2) aging the prepared sol at room temperature for 12 hours to obtain a gel;

[0032] 3) drying the obtained gel at 60°C for 6 hours to obtain a xerogel;

[0033] 4) The dry gel is carbonized with argon as a protective gas and kept at 900°C for 3 hours;

[0034] 5) The carbonized product was washed with deionized water until the pH of the solution was 6.8, and the solution was suction-filtered to obtain the product, which was dried at 60° C. for 5 hours to obtain three-dimensional graphene.

Embodiment 2

[0036] A kind of method that adopts ethyl cellulose to prepare three-dimensional graphene as raw material, comprises the following steps:

[0037] 1) Dissolve analytically pure ethylcellulose and NaOH in a molar ratio of 1:3 in an appropriate amount of ethanol (the mass ratio of ethanol: ethylcellulose and NaOH mixture is 15:1) to prepare a sol;

[0038] 2) aging the prepared sol at room temperature for 12 hours to obtain a gel;

[0039] 3) drying the obtained gel at 60°C for 6 hours to obtain a xerogel;

[0040] 4) The dry gel is carbonized with argon as a protective gas and kept at 700°C for 3 hours;

[0041] 5) The carbonized product was washed with deionized water until the pH of the solution was 7.0, and the solution was suction-filtered to obtain the product, which was dried at 60° C. for 5 hours to obtain three-dimensional graphene.

Embodiment 3

[0043] A kind of method that adopts ethyl cellulose to prepare three-dimensional graphene as raw material, comprises the following steps:

[0044] 1) Dissolve analytically pure ethylcellulose and NaOH in a molar ratio of 1:2 in an appropriate amount (the mass ratio of ethanol: ethylcellulose and NaOH mixture is 20:1) to prepare a sol;

[0045] 2) aging the prepared sol at room temperature for 12 hours to obtain a gel;

[0046] 3) drying the obtained gel at 60°C for 6 hours to obtain a xerogel;

[0047] 4) The dry gel is carbonized with argon as a protective gas and kept at 900°C for 3 hours;

[0048] 5) The carbonized product was washed with deionized water until the pH of the solution was 7.0, and the solution was suction-filtered to obtain the product, which was dried at 60° C. for 5 hours to obtain three-dimensional graphene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com