Rubber material for soles and preparation method thereof

A technology for rubber materials and soles, applied in the field of rubber materials for soles and their preparation, can solve the problems of unstable rubber sole manufacturing process, lack of elasticity, lack of anti-slip performance, and sole wear, and achieves good anti-slip and excellent product performance. , the effect of short operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

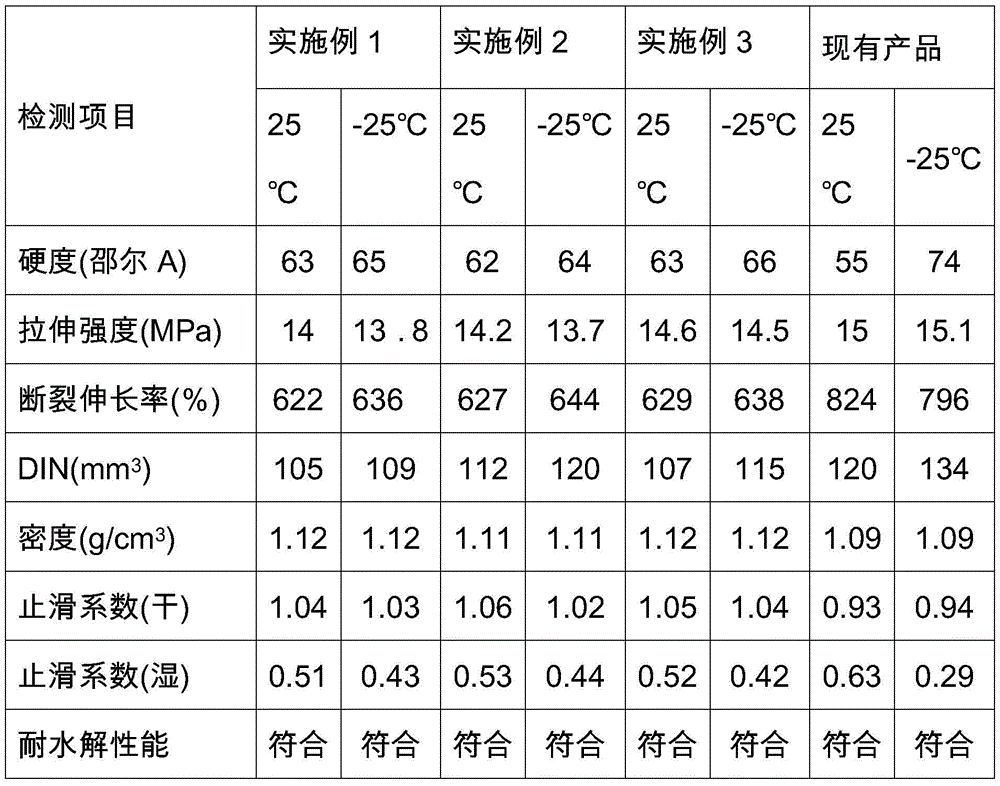

Examples

Embodiment 1

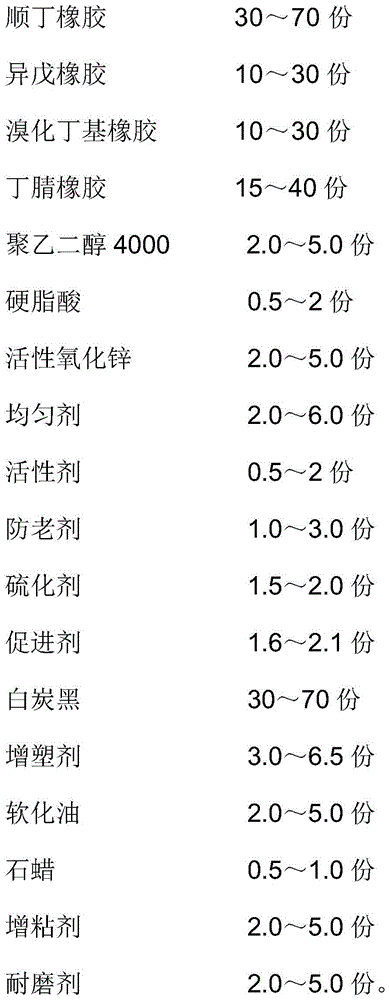

[0044]According to the aforementioned step 1, the following materials are prepared: 3000g of butadiene rubber, 3000g of isoprene rubber, 1000g of isobutylene-isoprene copolymer elastomer containing 20% active bromine by weight, 4000g of nitrile rubber, 500g of polyethylene glycol, Stearic acid 50g, active zinc oxide 500g, leveling agent 450g, activator 50g, di-tert-butyl-p-cresol 100g, sulfur 150g, accelerator 210g (this accelerator is made of thiazole class advance agent 111g, thiuram class accelerator 66g and dithiocarbamate accelerant 33g are mixed), white carbon black 7000g, plasticizer 400g, paraffin-based rubber softening oil 200g, paraffin 100g, tackifying resin 50g, wear-resistant agent 400g.

[0045] According to the aforementioned step 2: put the materials prepared in step 1 except the sulfur and the accelerator into the internal mixer for mixing, the mixing time is 9 minutes, and the temperature is 120-122°C.

[0046] The kneaded material is discharged from the in...

Embodiment 2

[0049] According to the aforementioned step 1, prepare the following materials: 9590g of butadiene rubber, 5480g of isoprene rubber, isobutylene-isoprene copolymer elastomer containing 15% active bromine by weight: 4110g, nitrile rubber: 8220g, polyethylene glycol Alcohol 1096g, stearic acid is 274g, activated zinc oxide is 822g, leveling agent 530g, activator 320g, di-tert-butyl-p-cresol is 274g, sulfur 400g, accelerator 500g (this advance agent is made of thiazoles accelerator 80g, Thiuram class accelerator 320g, dithiocarbamate class accelerator 100g mix and form), white carbon black 8220g, plasticizer 750g, paraffin-based rubber softening oil 548g, paraffin is 137g, tackifying resin 411g, Wear-resisting agent 480g.

[0050] According to the aforementioned step 2: put the materials prepared in step 1 except the sulfur and the accelerator into the internal mixer and knead for 7 minutes at a temperature of 130-132°C.

[0051] The kneaded material is discharged from the inter...

Embodiment 3

[0054] According to the previous step 1, prepare the following materials: 16170g of butadiene rubber, 7700g of isoprene rubber, active brominated isobutylene-isoprene copolymer elastomer: 5775g, nitrile rubber: 8855g, polyethylene glycol 1540g, stearin Acid 385g, active zinc oxide 1155g, leveling agent 510g, active agent 200g, di-tert-butyl-p-cresol 385g, sulfur: 600g, accelerator 750g (the accelerator consists of thiazole accelerator 120g, thiuram accelerator 480g , dithiocarbamate accelerator 150g mixed), white carbon black 15400g, plasticizer 1150g, paraffin-based rubber softening oil 770g, paraffin 193g, tackifying resin 578g, wear-resistant agent 550g.

[0055] According to the aforementioned step 2: put the materials prepared in step 1 except the sulfur and accelerator into the internal mixer and knead, the kneading time is 8 minutes, and the temperature is 138-140°C.

[0056] The kneaded material is discharged from the internal mixer and cooled to a temperature of 50-52...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com