High-surface-smoothness long-glass-fiber-reinforced polypropylene composite material and preparation method thereof

A technology of long glass fibers and polypropylene materials, applied in the field of polypropylene composite materials, can solve the problems of reducing the fluidity of crystalline polymer substrates, limiting applications, and increasing material costs, achieving good low VOC emission performance and simplifying production processes , the effect of excellent appearance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

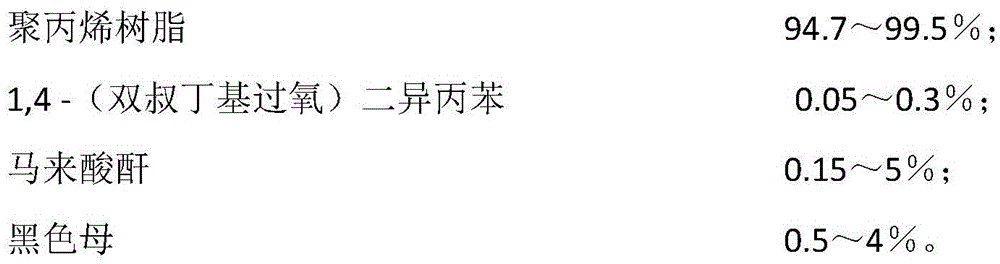

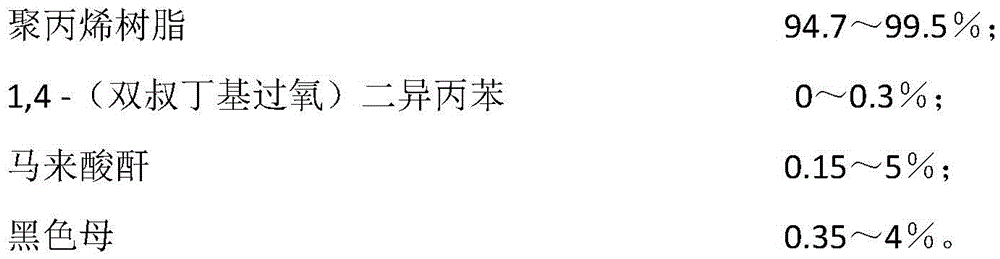

Method used

Image

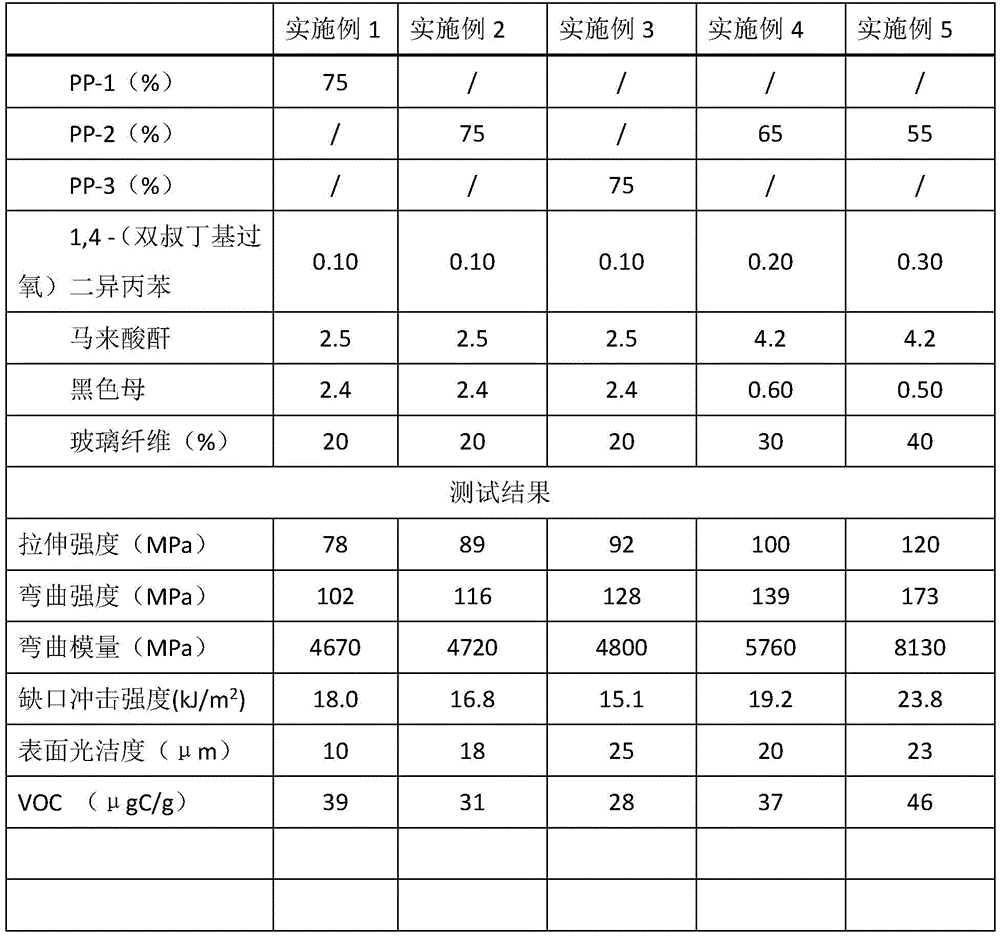

Examples

Embodiment 1

[0037] Use the TE-65 (length-to-diameter ratio 1 / D=48) twin-screw extruder with side feed port, add 1500 grams of polypropylene resin PP-1 at the main feed port, add 48 at the side feed port gram of black mother, 2 grams of 1,4-(bis-tert-butylperoxy)dicumene and 50 grams of maleic anhydride. The processing temperatures (from the feed port to the die) are: 150°C, 190°C, 200°C, 220°C, 240°C, 240°C, 260°C, 265°C, and the speed of the main machine is 350rpm.

[0038] The compound and the continuous glass fiber melted and reacted by the extruder adopt the pultrusion process, the impregnation temperature is 260°C, and the fiber weight percentage is 20% and the length is the same as the resin pellet. The long glass fiber reinforced PP pellets with the same material length were used to prepare standard mechanical test samples by injection molding machine. The test results are shown in Table 1.

Embodiment 2

[0040] Use the TE-65 (length-to-diameter ratio 1 / D=48) twin-screw extruder with side feed port, add 1500 grams of polypropylene resin PP-2 at the main feed port, add 48 at the side feed port gram of black mother, 2 grams of 1,4-(bis-tert-butylperoxy)dicumene and 50 grams of maleic anhydride. The processing temperatures (from the feed port to the die) are: 150°C, 190°C, 200°C, 220°C, 240°C, 240°C, 260°C, 265°C, and the speed of the main machine is 350rpm.

[0041] The compound and the continuous glass fiber melted and reacted by the extruder adopt the pultrusion process, the impregnation temperature is 260°C, and the fiber weight percentage is 20% and the length is the same as the resin pellet. The long glass fiber reinforced PP pellets with the same material length were used to prepare standard mechanical test samples by injection molding machine. The test results are shown in Table 1.

Embodiment 3

[0043] Use the TE-65 (length-to-diameter ratio 1 / D=48) twin-screw extruder with side feed port, add 1500 grams of polypropylene resin PP-3 at the main feed port, add 48 at the side feed port gram of black mother, 2 grams of 1,4-(bis-tert-butylperoxy)dicumene and 50 grams of maleic anhydride. The processing temperatures (from the feed port to the die) are: 150°C, 190°C, 200°C, 220°C, 240°C, 240°C, 260°C, 265°C, and the speed of the main machine is 350rpm.

[0044] The compound and the continuous glass fiber melted and reacted by the extruder adopt the pultrusion process, the impregnation temperature is 260°C, and the fiber weight percentage is 20% and the length is the same as the resin pellet. The long glass fiber reinforced PP pellets with the same material length were used to prepare standard mechanical test samples by injection molding machine. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com