Vanadium-doped calcium zirconate inorganic pigment and preparing method thereof

A technology of inorganic pigments and calcium zirconate, which is applied in the direction of inorganic pigment treatment, chemical instruments and methods, and fibrous fillers. Insufficient stain resistance, mitigation of heat island effect, and improvement of color performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the present invention comprises the following steps:

[0022] (1) According to the molar ratio of calcium carbonate: zirconia: vanadium pentoxide=1: (1-x): x, calcium carbonate, zirconia and vanadium pentoxide are used, wherein 0<x≤0.4.

[0023] (2) Dry ball mill the above raw materials for 24-48 hours and mix them evenly.

[0024] (3) Calcinate the mixture after dry ball milling at 1400-1700°C for 2-10 hours, after it is cooled, put it into a ball mill for 24-48 hours, and grind it into powder to obtain vanadium-doped zirconic acid Calcium inorganic pigments.

[0025] The vanadium-doped calcium zirconate inorganic pigment that the present invention makes is that chemical formula can be written as CaZr (1-x) V x o 3 , 0<x≤0.4, which is a perovskite structure.

Embodiment 1

[0028] According to the molar ratio of calcium carbonate: zirconia: vanadium pentoxide = 1:0.9:0.1, take the raw materials calcium carbonate, zirconia and vanadium pentoxide, put them into a ball mill for dry mixing and ball milling for 24 hours; the mixture after ball milling Calcined in a resistance furnace at 1600°C for 3 hours, after cooling, put it into a ball mill for 24 hours, and grind it into powder to obtain a yellow pigment sample, whose chemical formula is CaZr 0.9 V 0.1 o 3 .

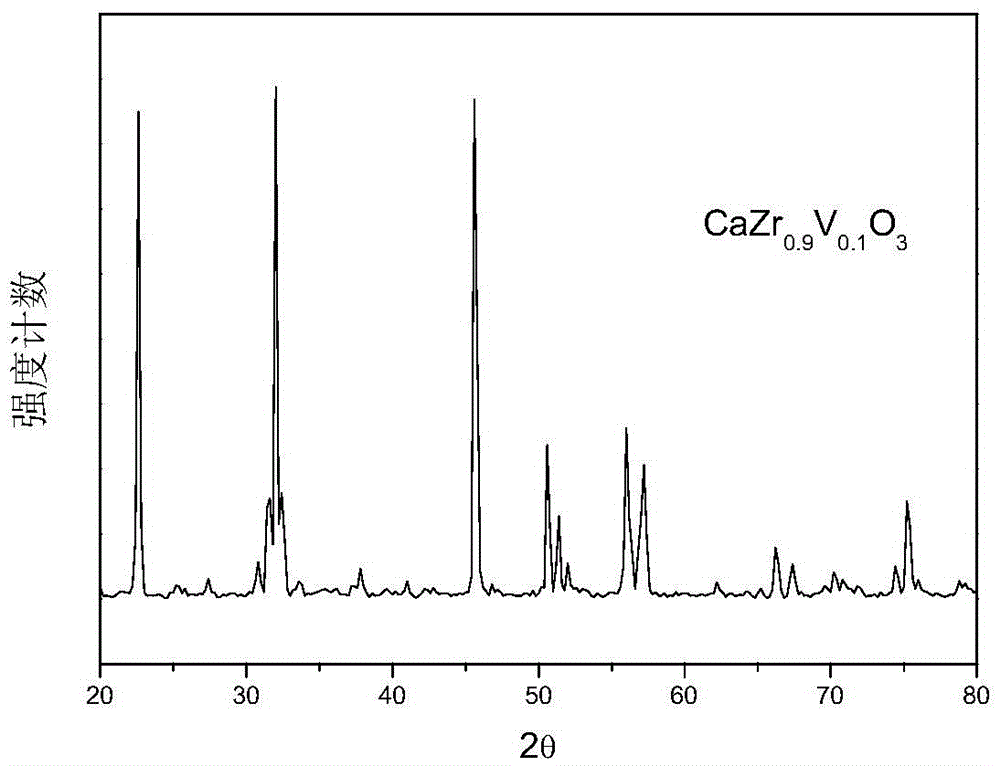

[0029] The prepared above-mentioned pigment samples were subjected to RigakuUltima Ⅳ X-ray diffractometer (XRD), using CuK in the range of 2θα1 (λ=0.15418nm) the obtained powder of radiation photodetection, XRD collection of patterns such as figure 1 As shown, it can be indicated as a perovskite phase.

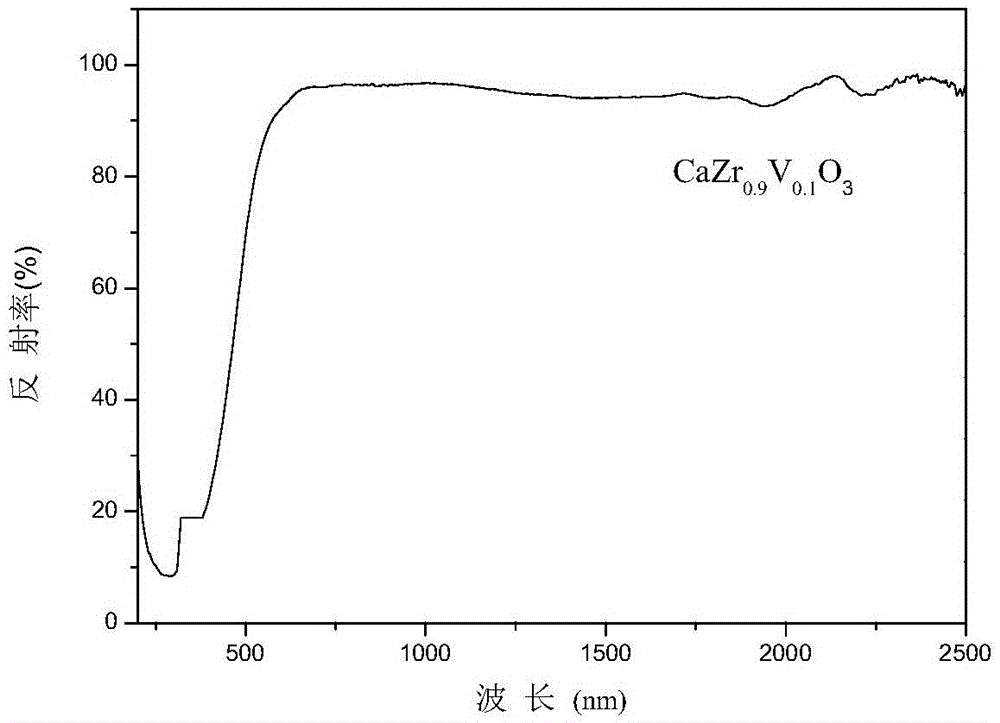

[0030] According to the CIE1976CIE color scale, the chromaticity coordinates of this embodiment are L*=93.66, a*=-4.73, b*=34.65, C*=34.97; values a* (red-green axis) and b* (yellow-bl...

Embodiment 2

[0042] According to the molar ratio of calcium carbonate: zirconia: vanadium pentoxide = 1:0.6:0.4, take the raw materials calcium carbonate, zirconia and vanadium pentoxide, put them into a ball mill for dry mixing and ball milling for 36 hours; the mixture after ball milling Calcined in a resistance furnace at 1400°C for 10 hours, after cooling, put it into a ball mill for 36 hours, and grind it into powder to obtain a yellow pigment sample, whose chemical formula is CaZr 0.6 V 0.4 o 3 .

[0043] The measured chromaticity coordinates of this embodiment are L*=97.05, a*=-3.01, b*=27.88, C*=28.04, and the near-infrared reflectivity is 83.74%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com