Oxygen lance for smelting of molten pool

A technology of molten pool smelting and oxygen lance, applied in the field of iron and steel smelting and blowing, can solve the problems of high frequency of downtime for maintenance and gun replacement, great influence on normal production of equipment, and backflow, etc., so as to improve the efficiency of oxygen use and improve the stirring effect. , the effect of convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

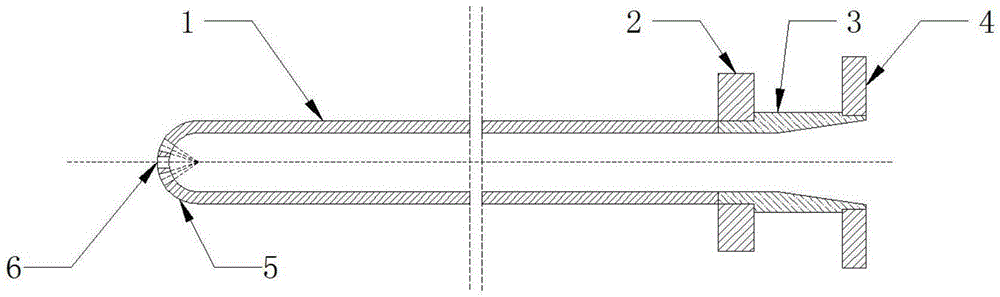

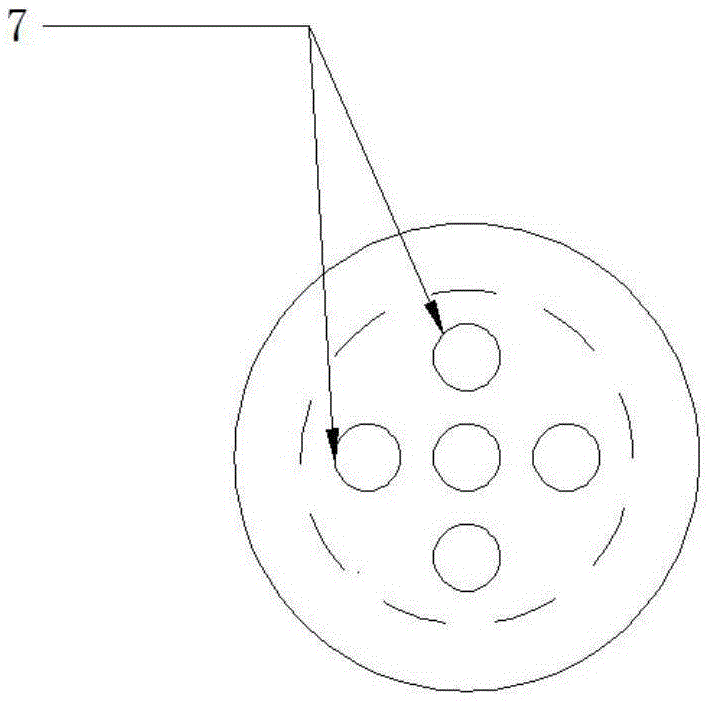

[0031] Such as figure 1 As shown, an oxygen lance for molten pool smelting includes a gun barrel 1, one end of the gun barrel 1 is a gas supply end, and the other end is an exhaust end, and the exhaust end of the gun barrel 1 is provided with a plurality of nozzle holes 7, and the gun barrel 1 is provided with a plurality of nozzle holes 7. The tube 1 is formed by hot die-casting or injection molding of silicon nitride powder, and is sintered once under normal pressure using a sintering aid. Because the silicon nitride material is a high-temperature-resistant ceramic material, it can withstand high temperatures of 1300°C to 1400°C, and has high-temperature resistance, high strength, and high hardness, which greatly improves the service life of the oxygen lance.

[0032] Slot-type multi-layer casing oxygen lance is generally made of heat-resistant stainless steel and requires protective gas because oxygen will oxidize with the melt after entering the molten pool, generating a l...

Embodiment 2

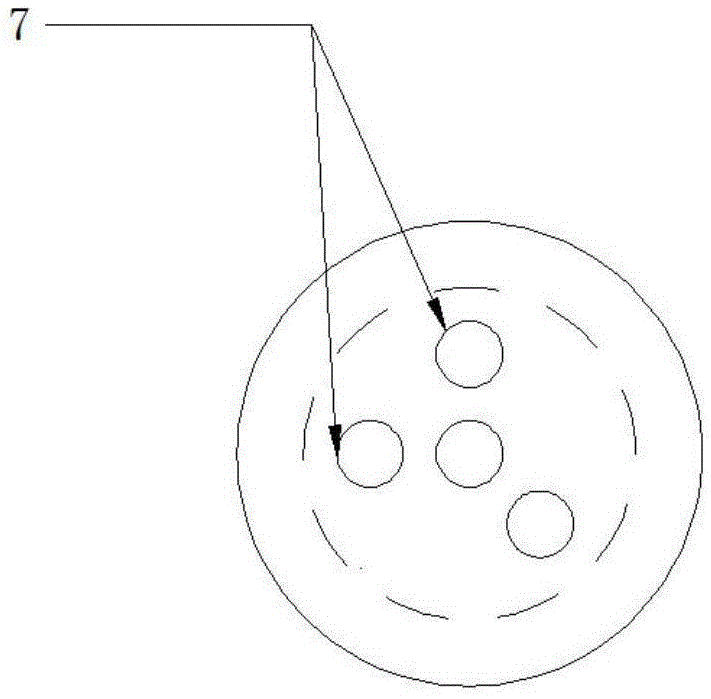

[0038] Such as image 3 As shown, there are 4 spray holes, and the 3 edge spray holes 7 are distributed asymmetrically.

[0039] All the other structures are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com