(Meth)acrylic resin

A technology of acrylic resin and methyl, which is applied in the direction of instruments, optics, optical components, etc., can solve the problems of large birefringence of resin, and achieve the effects of small photoelastic coefficient, excellent heat resistance, and high surface hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0147] (A) Preparation of (meth)acrylic resin

[0148] Into an autoclave with a capacity of 2 L, 29.5 parts by weight of methyl methacrylate [manufactured by Sumitomo Chemical Co., Ltd., trade name: SUMIPEX EX, weight average molecular weight: 140,000], 27.3 parts by weight of aniline, and 33.2 parts by weight of toluene were charged. This autoclave was heated up to 240 degreeC, and it stirred for 3 hours, and the reaction solution was obtained.

[0149] Next, the reaction solution obtained above is introduced into the cylinder at a processing speed of 300 g / hour in terms of resin amount, the temperature of the cylinder is 260 ° C, the rotation speed is 70 rpm, the degree of vacuum is 13.3 hPa to 400 hPa (10 mmHg to 300 mmHg), and the number of rear exhaust ports is 1 In a vented twin-screw extruder (hole diameter: 15mm, L / D: 45) with two front vent ports, devolatilization is performed in the extruder and extruded to obtain transparent particles of (meth)acrylic resin. The (...

Embodiment 2

[0182] (A) Preparation of (meth)acrylic resin

[0183] In Example 1, except having changed the reaction temperature of the autoclave into 245 degreeC, it carried out similarly to Example 1, and obtained the (meth)acrylic-type resin. The obtained (meth)acrylic resin had a weight average molecular weight of 100,000.

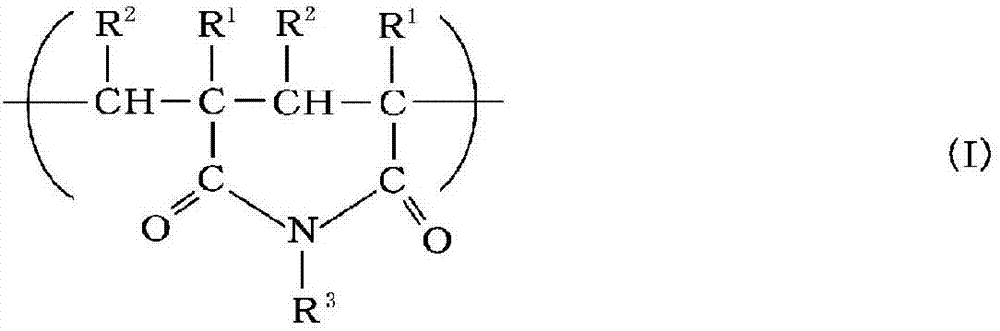

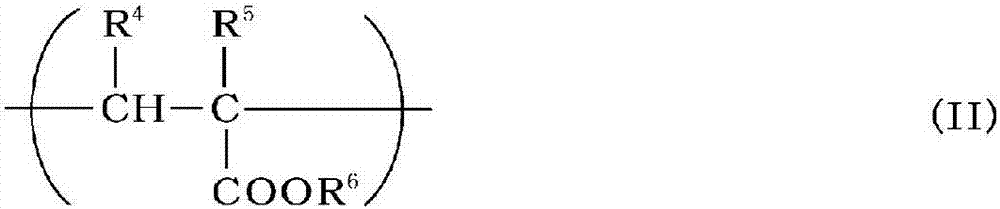

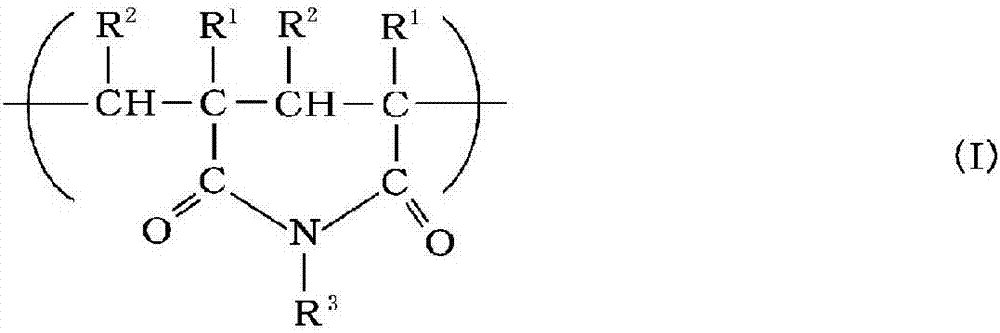

[0184] The (meth)acrylic resin obtained above is the following (meth)acrylic resin: R in formula (I) 1 is methyl, R 2 is a hydrogen atom, R 3 is a repeating unit of phenyl and R in formula (II) 4 is a hydrogen atom, R 5 is methyl, R 6 It is a repeating unit of methyl group, and its glass transition temperature is 152°C. The imidation rate of this (meth)acrylic resin, content of the repeating unit represented by formula (II), and stress optical coefficient (Cr) were investigated similarly to Example 1. As a result, the imidization rate of the (meth)acrylic resin was 20.9%, the content of the repeating unit represented by the formula (II) was 60.4% by weight, ...

Embodiment 3

[0190] (A) Preparation of (meth)acrylic resin

[0191] In Example 1, except having changed the reaction temperature of the autoclave into 247 degreeC and cylinder temperature into 270 degreeC, it carried out similarly to Example 1, and obtained the (meth)acrylic resin. The obtained (meth)acrylic resin had a weight average molecular weight of 90,000.

[0192] The (meth)acrylic resin obtained above is the following (meth)acrylic resin: R in formula (I) 1 is methyl, R 2 is a hydrogen atom, R 3 is a repeating unit of phenyl and R in formula (II) 4 is a hydrogen atom, R 5 is methyl, R 6 It is a repeating unit of methyl group, and its glass transition temperature is 160°C. The imidation rate of this (meth)acrylic resin, content of the repeating unit represented by formula (II), and stress optical coefficient (Cr) were investigated similarly to Example 1. As a result, the imidization ratio of the (meth)acrylic resin was 23.9%, the content of the repeating unit represented by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| photoelasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com