Processing method of frozen prepared cultured large yellow croaker

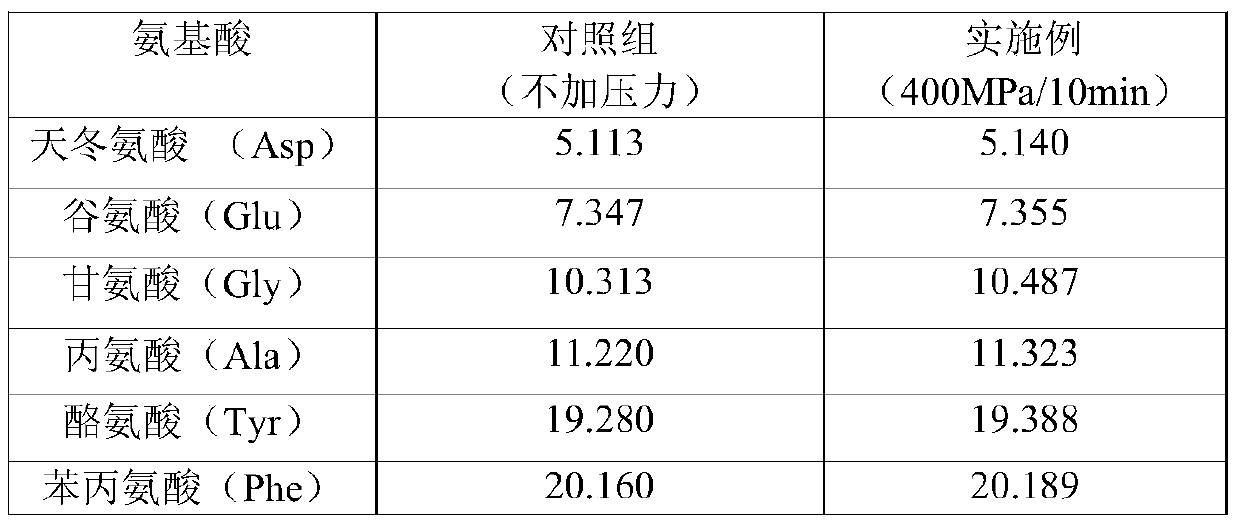

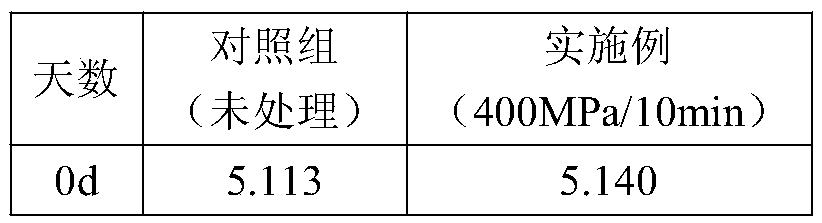

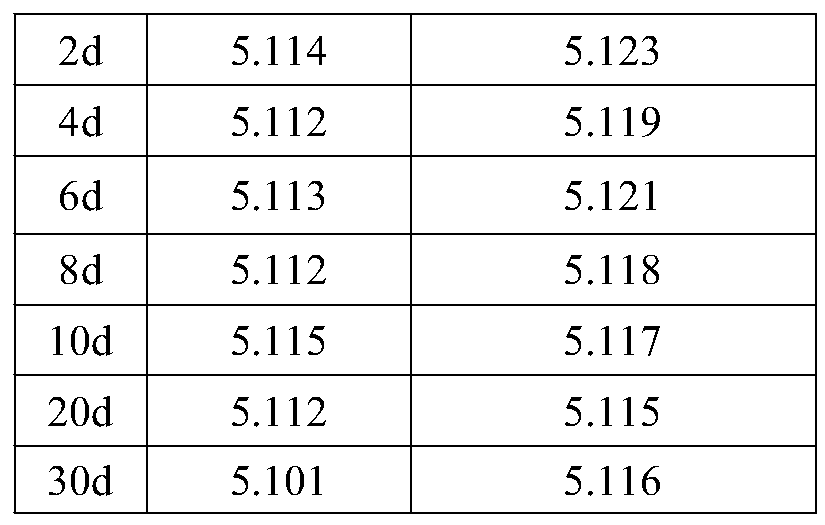

A technology of freezing conditioning and processing methods, applied in the direction of freezing/cooling preservation of meat/fish, food science, etc., can solve the problems of large yellow croaker's flavor components loss, uneven taste distribution, and reduced umami taste, so as to improve the seasoning effect , Guarantee the quality, improve the effect of umami taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The processing method of present embodiment freeze conditioning culture large yellow croaker, comprises the following steps:

[0023] (1) Raw material pretreatment: remove the scales, viscera and gills of the large yellow croaker, and clean the blood and impurities;

[0024] (2) Cleaning: the large yellow croaker obtained by processing in step (1) is cleaned with a concentration of 35g / L of sodium chloride solution;

[0025] (3) Drain: Drain at room temperature or blow dry the water on the surface of the fish with cold wind;

[0026] (4) Seasoning: dip the drained large yellow croaker into the seasoning solution for seasoning. The seasoning solution can be added with cooking wine, sucrose, salt, pepper, pepper and other formulas according to the needs of the product. The specific formula is configured according to the processing requirements;

[0027] (5) Packing: Put the large yellow croaker that is seasoned and not drained in step (4) into a vacuum packaging machine ...

Embodiment 2

[0046] The processing method of present embodiment freeze conditioning culture large yellow croaker, comprises the following steps:

[0047] (1) Raw material pretreatment: remove the scales, viscera and gills of the large yellow croaker, and clean the blood and impurities;

[0048] (2) Cleaning: the large yellow croaker obtained by processing in step (1) is cleaned with a concentration of 32g / L of sodium chloride solution;

[0049] (3) Drain: Drain at room temperature or blow dry the water on the surface of the fish with cold wind;

[0050] (4) Seasoning: dip the drained large yellow croaker into the seasoning solution for seasoning. The seasoning solution can be added with cooking wine, sucrose, salt, pepper, pepper and other formulas according to the needs of the product. The specific formula is configured according to the processing requirements;

[0051] (5) Packing: Put the large yellow croaker that is seasoned and not drained in step (4) into a vacuum packaging machine ...

Embodiment 3

[0058] The processing method of present embodiment freeze conditioning culture large yellow croaker, comprises the following steps:

[0059] (1) Raw material pretreatment: remove the scales, viscera and gills of the large yellow croaker, and clean the blood and impurities;

[0060] (2) Cleaning: the large yellow croaker obtained by processing in step (1) is cleaned with a concentration of 38g / L of sodium chloride solution;

[0061] (3) Drain: Drain at room temperature or blow dry the water on the surface of the fish with cold wind;

[0062] (4) Seasoning: dip the drained large yellow croaker into the seasoning solution for seasoning. The seasoning solution can be added with cooking wine, sucrose, salt, pepper, pepper and other formulas according to the needs of the product. The specific formula is configured according to the processing requirements;

[0063] (5) Packing: Put the large yellow croaker that is seasoned and not drained in step (4) into a vacuum packaging machine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com