High-performance catalyst for preparation of benzene by cyclotrimerization of acetylene as well as preparation method and application thereof

A catalyst and cyclotrimerization technology, which is applied in the direction of catalysts, molecular sieve catalysts, carbon compound catalysts, etc., can solve problems such as difficult industrial applications, and achieve the effects of mild reaction conditions, simple operation, and great application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

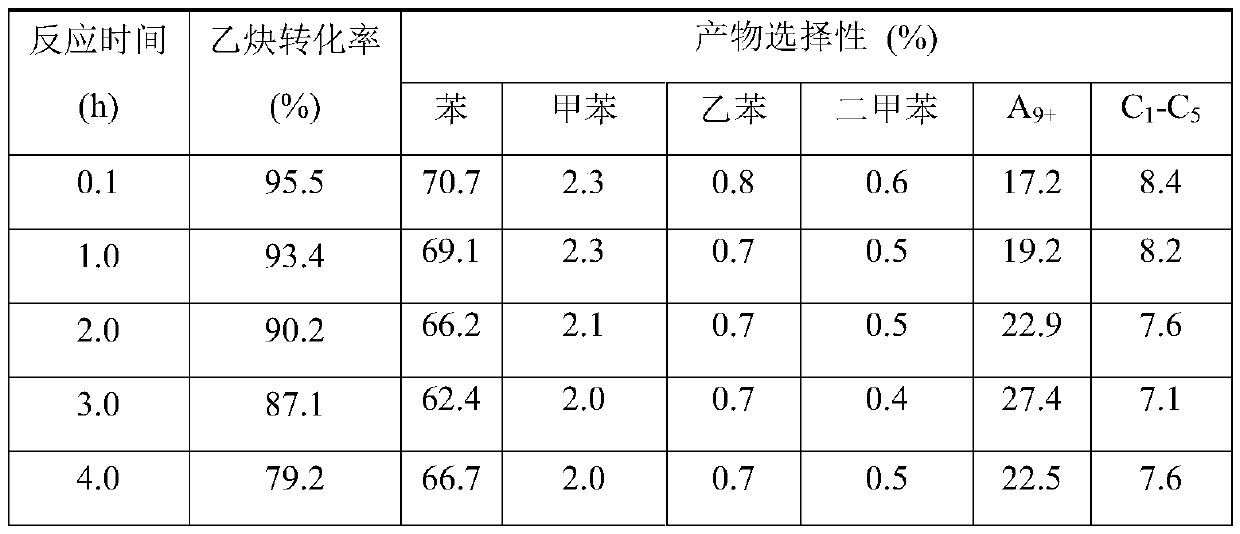

Embodiment 1

[0022] Pd / Ru / Rh / SiO 2 Catalyst preparation

[0023] The macroporous silica gel was calcined in an air atmosphere at 500°C for 6 hours and then reduced to room temperature. Weighed 50g of the calcined macroporous silica gel carrier and added the same volume to PdCl 2 In aqueous solution, PdCl 2 The loading amount is recorded as 0.5% of the macroporous silica gel by the mass of Pd, and immersed for 6h at room temperature. After the resulting mixture is dried at 110°C, it is heated at 10°C / min to 500°C in an air atmosphere and calcined for 3h to obtain Pd / SiO supported by macroporous silica gel. 2 Catalyst, denoted as Pd(0.5) / SiO 2 .

[0024] Then, add the same volume of the catalyst to RuCl 3 And RhCl 3 In mixed water solution, RuCl 3 And RhCl 3 The loading amount is recorded as 0.2% and 1.3% of the macroporous silica gel based on the mass of Ru and Rh, and immersed for 10 hours at room temperature. The resulting mixture was dried at 110°C, and then heated at 10°C / min to 550°C in an ...

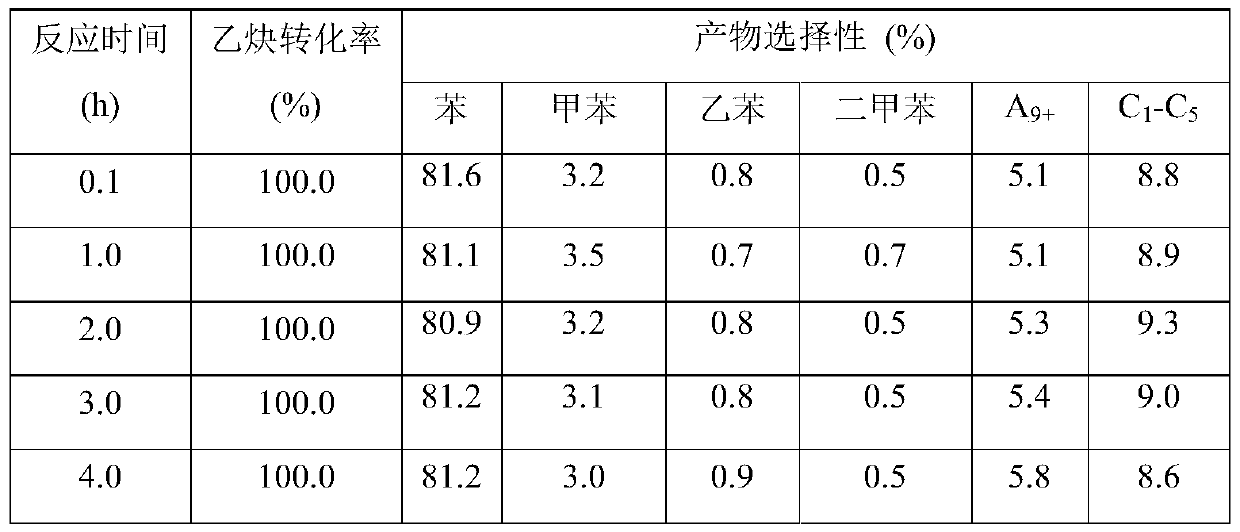

Embodiment 2

[0026] Preparation of Pd / Ru / Rh / MCM-41 catalyst

[0027] The MCM-41 was calcined at 500°C in an air atmosphere for 6 hours and then lowered to room temperature. Weighed 50g of the calcined MCM-41 carrier, and impregnated it with PdCl in an equal volume. 2 Aqueous solution, PdCl 2 The load is recorded as 0.5% of MCM-41 by the mass of Pd, and it is immersed in an aqueous solution for 6 hours at room temperature. The resulting mixture was dried at 110°C, and then heated at 10°C / min to 550°C in an air atmosphere and calcined for 3 hours to obtain the MCM-41 supported Pd / MCM-41 catalyst, denoted as Pd(0.5) / MCM-41 .

[0028] Impregnate the sample in an equal volume and add RuCl 3 And RhCl 3 In the mixed aqueous solution, RuCl 3 And RhCl 3 The loading amount is recorded as 0.2% and 1.3% of MCM-41 in terms of Ru and Rh masses. After being configured as an aqueous solution, it is immersed at room temperature for 10 hours. After the resulting mixture was dried at 110°C, it was heated at 10°C...

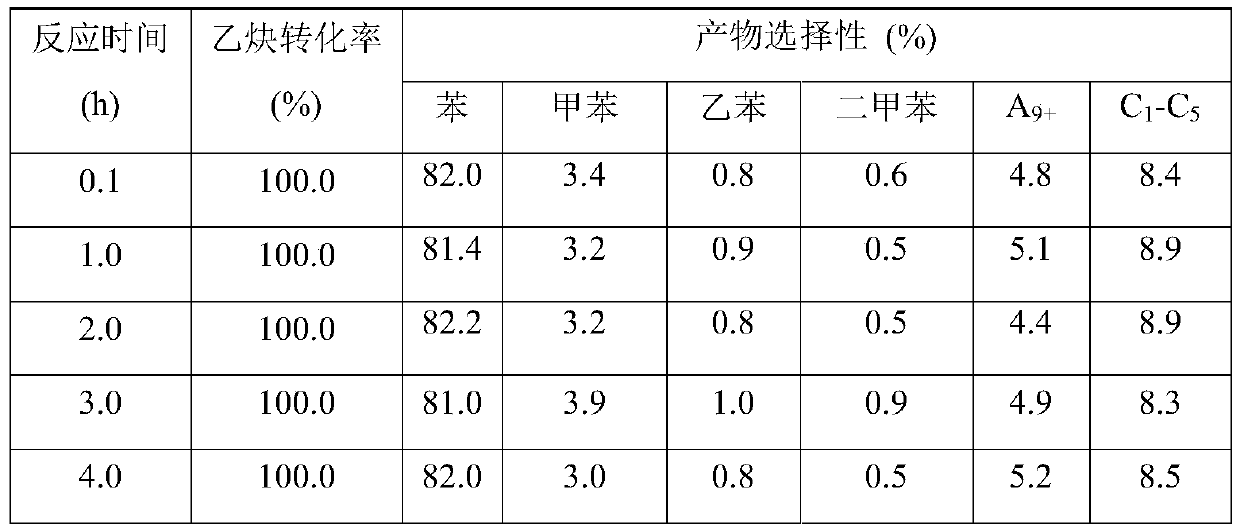

Embodiment 3

[0030] Preparation of Pd / Ru / Rh / SBA-15 catalyst

[0031] The SBA-15 was calcined in an air atmosphere at 500°C for 6 hours and then lowered to room temperature. Weighed 50g of the calcined SBA-15 carrier, and impregnated it with PdCl in an equal volume. 2 Aqueous solution, PdCl 2 The load is recorded as 0.5% of SBA-15 by the mass of Pd, and it is immersed in an aqueous solution for 12 hours at room temperature. The resulting mixture was dried at 110°C, and then heated at 10°C / min to 550°C in an air atmosphere and calcined for 3 hours to obtain the SBA-15 supported Pd / SBA-15 catalyst, which was recorded as Pd(0.5) / SBA-15 .

[0032] Impregnate the sample in an equal volume and add RuCl 3 And RhCl 3 In the mixed aqueous solution, RuCl 3 And RhCl 3 The loading amount is 0.5% and 1% of SBA-15 in terms of Ru and Rh mass. After being prepared as an aqueous solution, it is immersed at room temperature for 6 hours. After the resulting mixture was dried at 110°C, it was heated at 10°C / min to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com