Glass solidification stabilization method for treating aluminum electrolysis waste slot lining based on F-Si chemical bond

A technology of vitrification and waste tank lining, applied in the direction of solid waste removal, etc., can solve the problems of difficult solidification conversion, environmental risks of incineration residues, high fluoride content, etc., and achieve strong stability, easy storage and transfer, and small volume Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

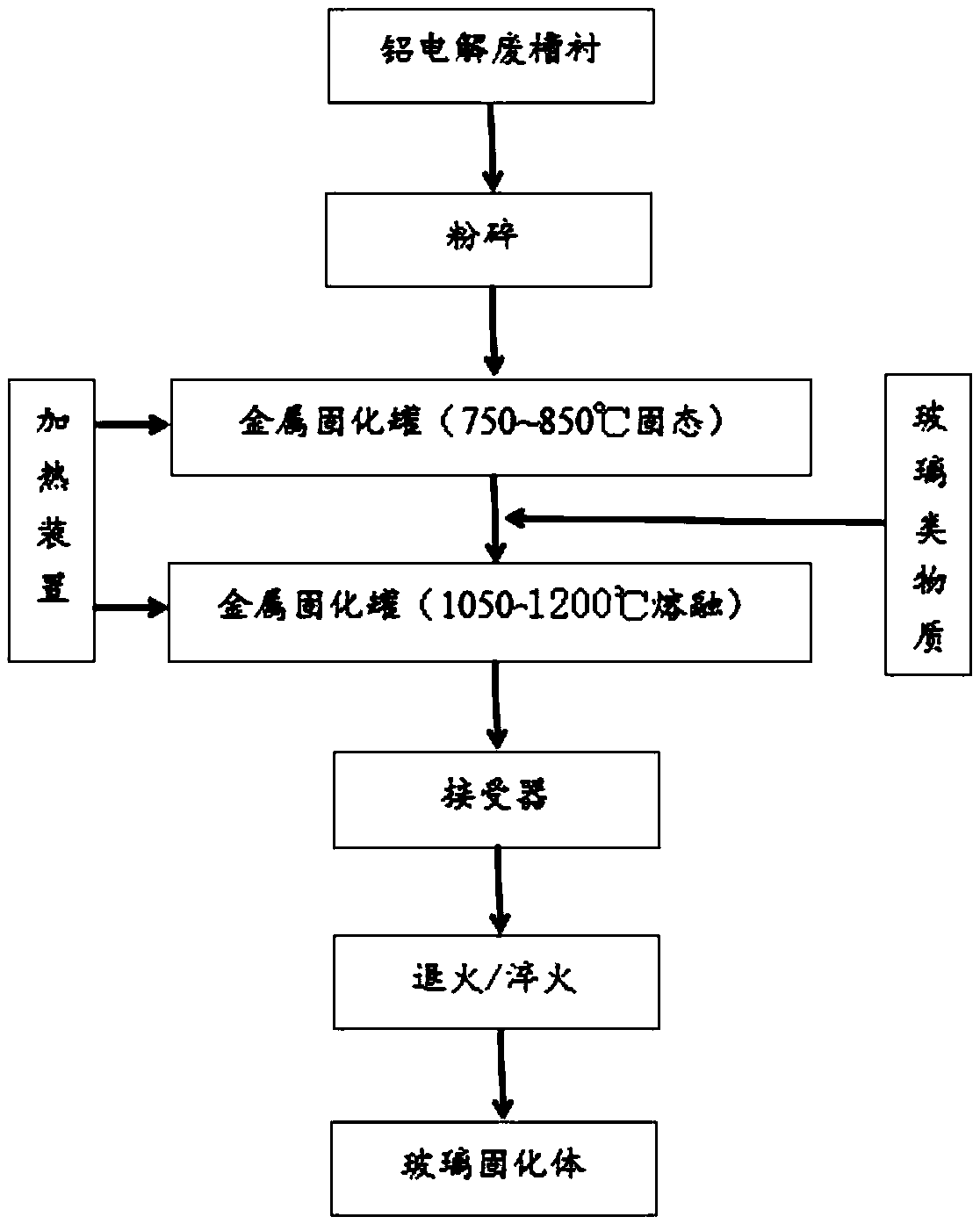

[0014] The method for stabilizing vitrification based on F-Si chemical bond treatment of aluminum electrolysis waste tank lining of the present invention, its preferred embodiment is:

[0015] Include steps:

[0016] A. Crushing the waste tank lining into particles with a particle size of less than 15mm;

[0017] B. Put the crushed waste tank lining into a metal curing tank equipped with a thermal induction device, carry out medium-temperature calcination through the heating device, and seal the generated dust in the curing tank, control the temperature at 750-850°C, and keep warm for 2 ~3.5 hours to realize the combustion capacity of carbonaceous components in the waste tank lining and the harmless pyrolysis of cyanide;

[0018] C. After medium-temperature calcination, add glass-like substances 0.8 to 2.0 times the weight of the waste tank lining into the metal curing tank as a curing agent;

[0019] D. Continue calcination, raise the temperature to 1050-1200°C, and keep th...

Embodiment 1

[0031] Firstly, the waste tank lining is broken into particles with a particle size of less than 10mm, weighed 1500g, puts it into a metal curing tank equipped with a thermal induction device, conducts closed heating and calcination by a heating device, and controls the temperature at 830°C for 3 hours. After medium-temperature calcination, add 2,500 g of waste cullet into the curing tank as a curing agent, continue calcination and raise the temperature to 1150° C., keep the temperature for 3.5 hours, and the mixture in the curing tank is in a molten state. Then, under controlled conditions, the molten glassy mixture flows from the metal solidification tank into a receiving container with a certain shape, and after rapid cooling through a quenching procedure, a vitrified solidified body containing waste tank lining fluoride is obtained.

[0032] According to the hazardous waste identification standard and leaching toxicity standard (GB5085.3-2007), the final vitrified solidifie...

Embodiment 2

[0034] First, the waste tank lining is broken into particles with a particle size of less than 5mm, weighed 1000g and placed in a metal curing tank equipped with a thermal induction device, and is closed and heated by a heating device for calcination. The temperature is controlled at 800°C and kept for 2.5 hours. After medium-temperature calcination, add 1,500 g of waste cullet into the curing tank as a curing agent, continue the calcination and raise the temperature to 1100°C, keep the temperature for 3 hours, and the mixture in the curing tank is in a molten state. Then, under controlled conditions, the molten glassy mixture flows from the metal solidification tank into a receiving container with a certain shape, and after rapid cooling through a quenching procedure, a vitrified solidified body containing waste tank lining fluoride is obtained.

[0035] According to the hazardous waste identification standard and leaching toxicity standard (GB5085.3-2007), the final glass sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com