Preparation method of micropore-developed activated carbon

An activated carbon, a developed technology, is applied in the field of preparation of microporous activated carbon, which can solve the problems of diversified pore size distribution and small micropore ratio, and achieve the effects of excellent performance, strong adsorption and good removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

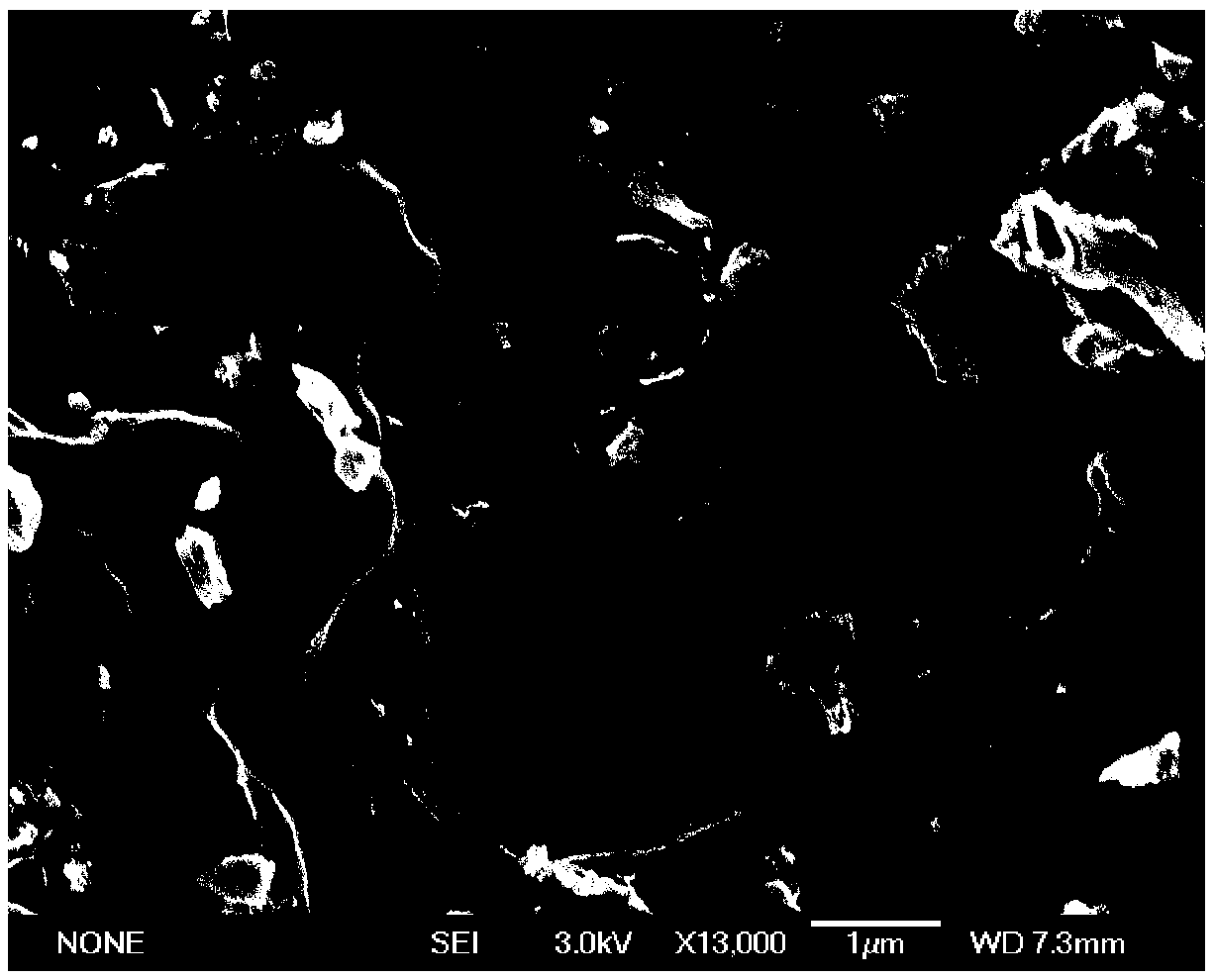

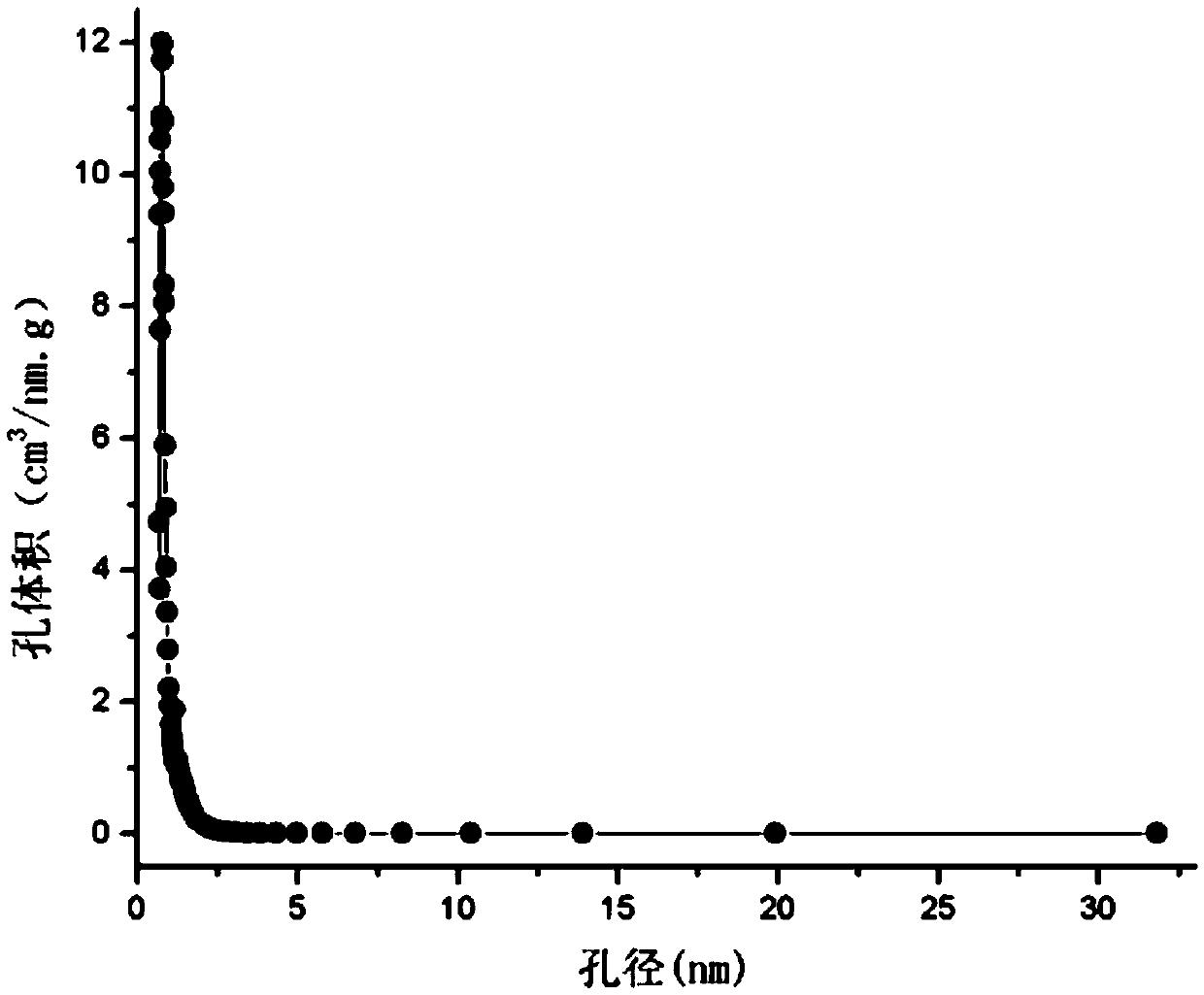

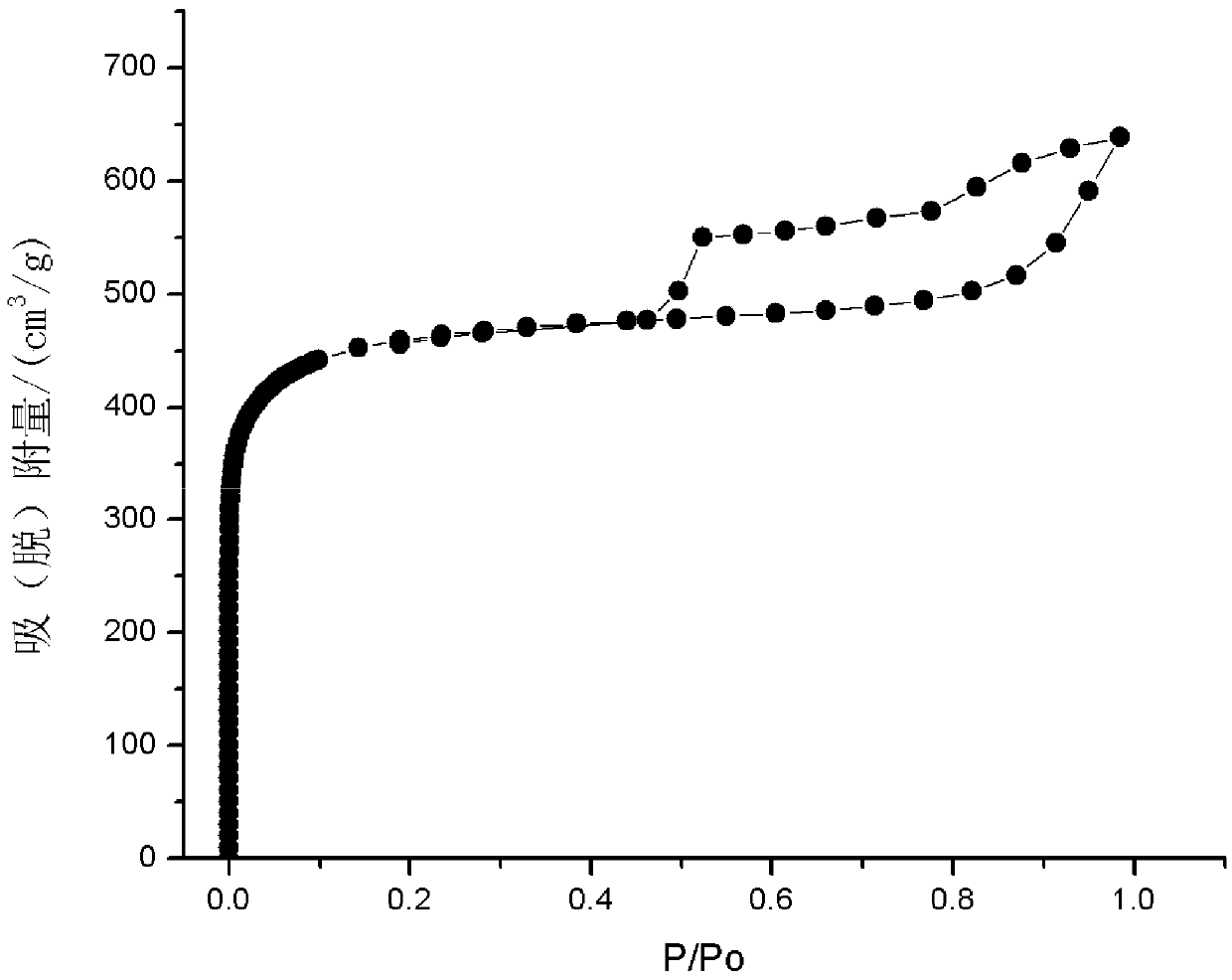

Image

Examples

Embodiment 1

[0028] A preparation method of activated carbon with developed micropores includes the following steps:

[0029] (1) The Enteromorpha powder is dried and crushed and passed through a 40-mesh sieve. The Enteromorpha powder is heated in a crucible with a lid in a carbonization furnace, and the heating rate is controlled at 5°C / min. After the temperature is raised, the material is maintained at 700°C and heated for 10 minutes. After being discharged from the furnace, the Enteromorpha carbonized material is obtained.

[0030] (2) Add potassium tartrate to the carbonized material of Enteromorpha in a mass ratio of 3:1, mix well, add deionized water, stir well; dry in a 110 ℃ oven to obtain the mixture .

[0031] (3) Put the processed mixture in step (2) into the tubular resistor, under the protection of nitrogen, heat up to 800℃, activate for 1h, stop heating, cool to room temperature, and take it out; wash with 4% dilute hydrochloric acid, Wash with deionized water to a pH of 6.5-7.0, ...

Embodiment 2

[0034] A preparation method of activated carbon with developed micropores includes the following steps:

[0035] (1) Enteromorpha powder is obtained by drying Enteromorpha powder and pulverizing it through a 40-mesh sieve. The Enteromorpha powder is heated in a crucible with a lid in a carbonization furnace, and the heating rate is controlled at 5°C / min. After the temperature is raised, the material is maintained at 700°C and heated for 10 minutes. After being discharged from the furnace, the Enteromorpha carbonized material is obtained.

[0036] (2) Add potassium tartrate to the carbonized material of Enteromorpha enterocarp at a mass ratio of 2:1, mix well, add deionized water, and stir evenly; dry in a 110 ℃ oven to obtain the mixture .

[0037] (3) Put the processed mixture in step (2) into a tubular resistor, under the protection of nitrogen, heat up to 700°C, activate for 0.5h, stop heating, cool to room temperature, and take it out; wash with 4% dilute hydrochloric acid, Aft...

Embodiment 3

[0039] A preparation method of activated carbon with developed micropores includes the following steps:

[0040] (1) Enteromorpha powder is obtained by drying Enteromorpha powder and pulverizing it through a 40-mesh sieve. The Enteromorpha powder is heated in a crucible with a lid in a carbonization furnace, and the heating rate is controlled at 5°C / min. After the temperature is raised, the material is maintained at 700°C and heated for 10 minutes. After being discharged from the furnace, the Enteromorpha carbonized material is obtained.

[0041] (2) Potassium tartrate was added to the carbonized material of Enteromorpha according to the mass ratio of potassium tartrate to the carbonized material of Enteromorpha japonica, mixed evenly, added deionized water, and stirred evenly; dried in a 110 ℃ oven to obtain the mixture .

[0042] (3) Put the processed mixture in step (2) into the tubular resistor, under the protection of nitrogen, heat up to 900℃, activate for 1 hour, stop heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com