Waterborne bi-component bright white finish and application thereof

A two-component, white topcoat technology, applied in the field of bright white topcoat, to achieve the effect of long pot life, high hardness and easy emulsification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

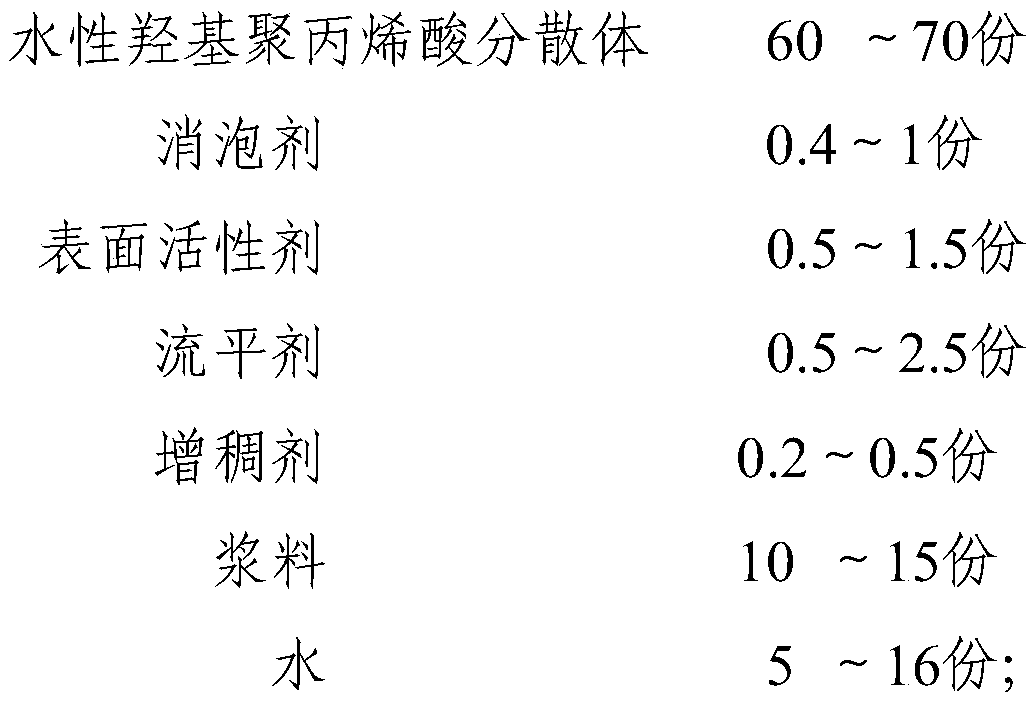

[0039] This embodiment provides a water-based two-component bright white topcoat, its composition and specific preparation process are as follows:

[0040] A component:

[0041] First add 6.5kg of water-based hydroxyl polyacrylic acid dispersion 2470, 0.5kg of water, 0.02kg of pH regulator AMP95 into the dispersion container, adjust the pH to 8-8.5, 0.3kg of dipropylene glycol butyl ether DPNB, 0.2kg of dipropylene glycol methyl ether DPM, 0.05 Add kg defoamer BYK024, 0.1kg surfactant F204E, 0.2kg acrylate leveling agent PW336 into the dispersion container in turn, stir well and add 1.2kg titanium white paste (70%), 0.05kg thickener RM2050D to disperse for 15 minutes , Stir 1kg of water evenly.

[0042] B component:

[0043] Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

[0044] During construction, the ratio of component A and component B is 100:14 and mixed evenly.

Embodiment 2

[0046] The present embodiment provides a kind of water-based two-component bright white finish paint, and the preparation process is the same as in Example 1, and the difference is that the composition of the water-based two-component bright white finish paint of the present embodiment is as follows:

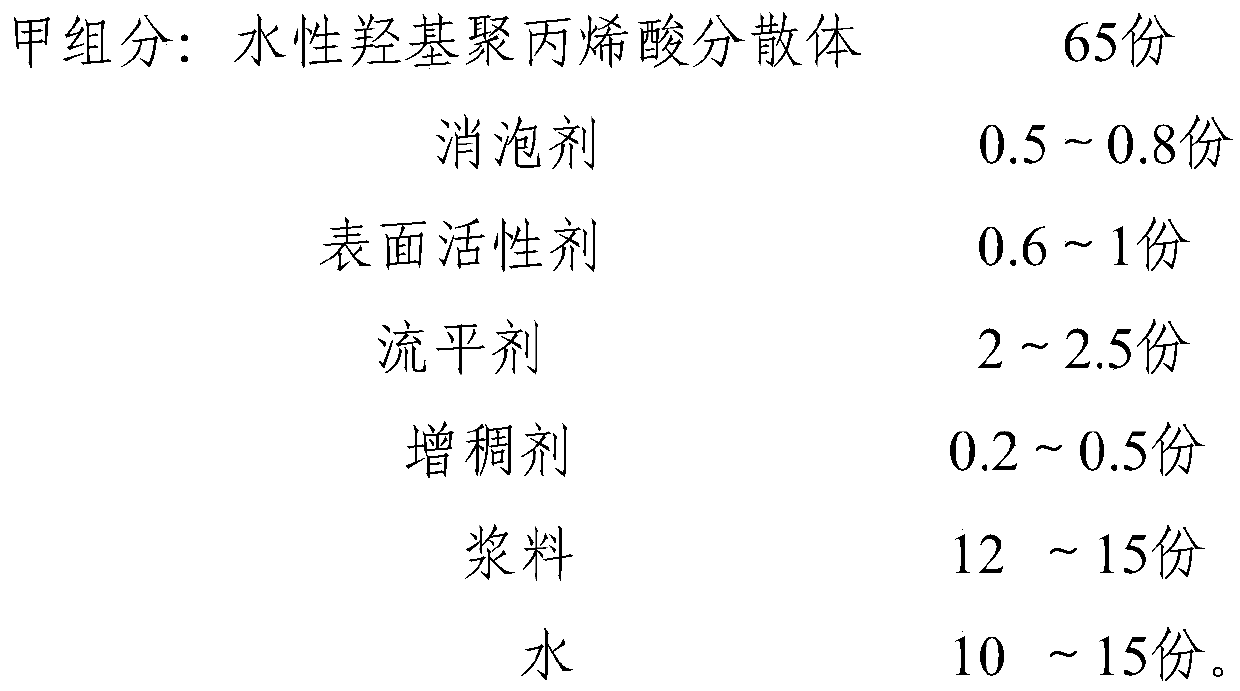

[0047] A component:

[0048]

[0049]

[0050] Component B: Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

[0051] During construction, mix evenly according to the weight ratio of component A and component B at 100:20.

Embodiment 3

[0053]This embodiment provides a kind of water-based two-component bright white finish paint, and the preparation process is the same as in Example 1, and the difference is that the composition of the water-based two-component bright white finish paint of the present embodiment is as follows (water is divided into two parts and used):

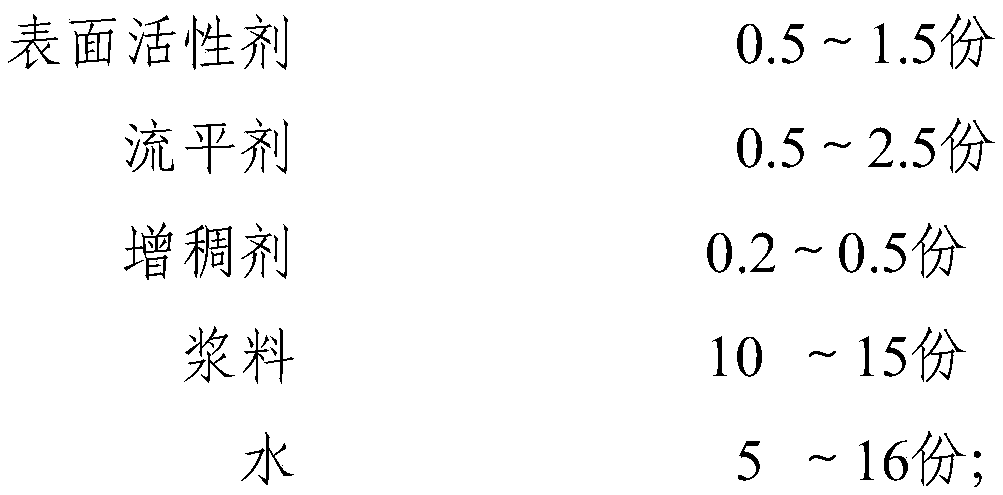

[0054] A component:

[0055]

[0056]

[0057] Component B: Hydrophilic aliphatic polyisocyanate based on hexamethylene diisocyanate (HDI).

[0058] During construction, mix evenly according to the weight ratio of component A and component B at 100:15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com