Cold zinc-sprayed anticorrosion coating doped with modified graphene

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of discount in the performance of coatings, unsatisfactory effects, and inability to disperse coatings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

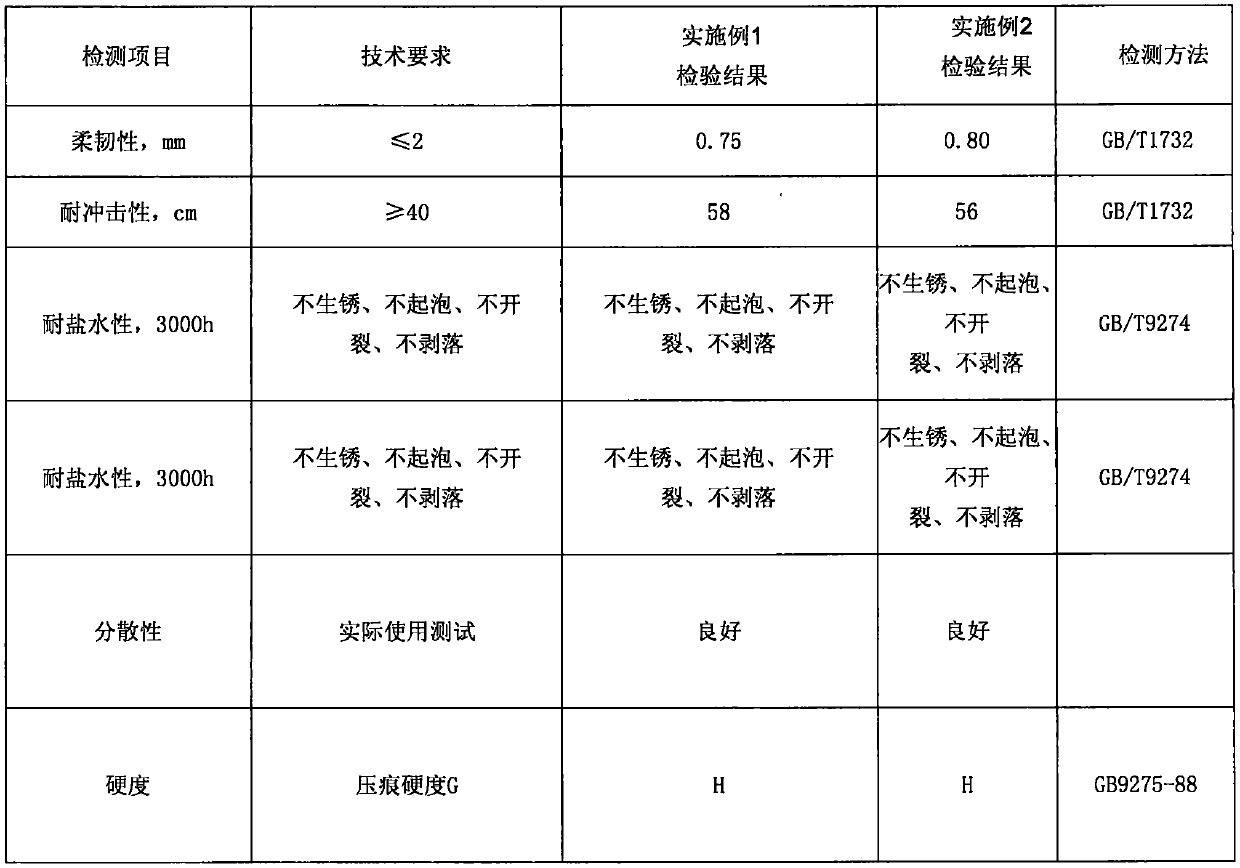

Embodiment 1

[0013] The preparation method of the cold-sprayed zinc anticorrosion coating mixed with modified graphene of the present invention comprises the following steps: first, the product proportion is drawn up as, and the weight parts of its composition raw materials are: modified graphene 80, polypropylene vinyl acetate 15 , epoxy resin 38, zinc powder 210, talcum powder 40, defoamer 20, leveling agent 8, curing agent 8, filler 70, and component B includes polyborosiloxane 40, aluminum powder 70, citric acid Triethyl ester 16, the modified graphene is to exchange the vinylbenzyl group in imidazole to the edge of graphene by ion exchange, and then polymerize with methyl methacrylate to obtain graphene polymethyl methacrylate Ester composite material, i.e. modified graphene; Specifically, the preferred filler in this embodiment is selected from a silica solution, and the silica solution is selected from a nanoscale silica solution with a three-dimensional network structure; The parti...

Embodiment 2

[0015] The preparation method of the cold-sprayed zinc anticorrosion coating mixed with modified graphene of the present invention comprises the following steps: first, the product proportion is drawn up, and the parts by weight of its composition raw materials are: modified graphene 50, polypropylene vinyl acetate 10 , epoxy resin 20, zinc powder 70, talcum powder 17, defoamer 10, leveling agent 5, curing agent 5, filler 30-70, and component B includes polyborosiloxane 30, aluminum powder 60, Triethyl citrate 14; the modified graphene is to exchange the vinylbenzyl group in imidazole to the edge of graphene by ion exchange, and then polymerize with methyl methacrylate to obtain graphene polymethyl Methyl acrylate composite material, that is, modified graphene; specifically, the preferred filler in this embodiment is selected from a silica solution, and the silica solution is selected from nanoscale silica with a three-dimensional network structure solution; the particle diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com