Liquid optically clear adhesive for full lamination

An optical adhesive, liquid technology, applied in the direction of adhesive, adhesive type, adhesive additive, etc., can solve the problem of optical properties such as refractive index not meeting the requirements, and achieve excellent yellowing resistance, low curing shrinkage, The effect of reducing the loss of transmitted light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

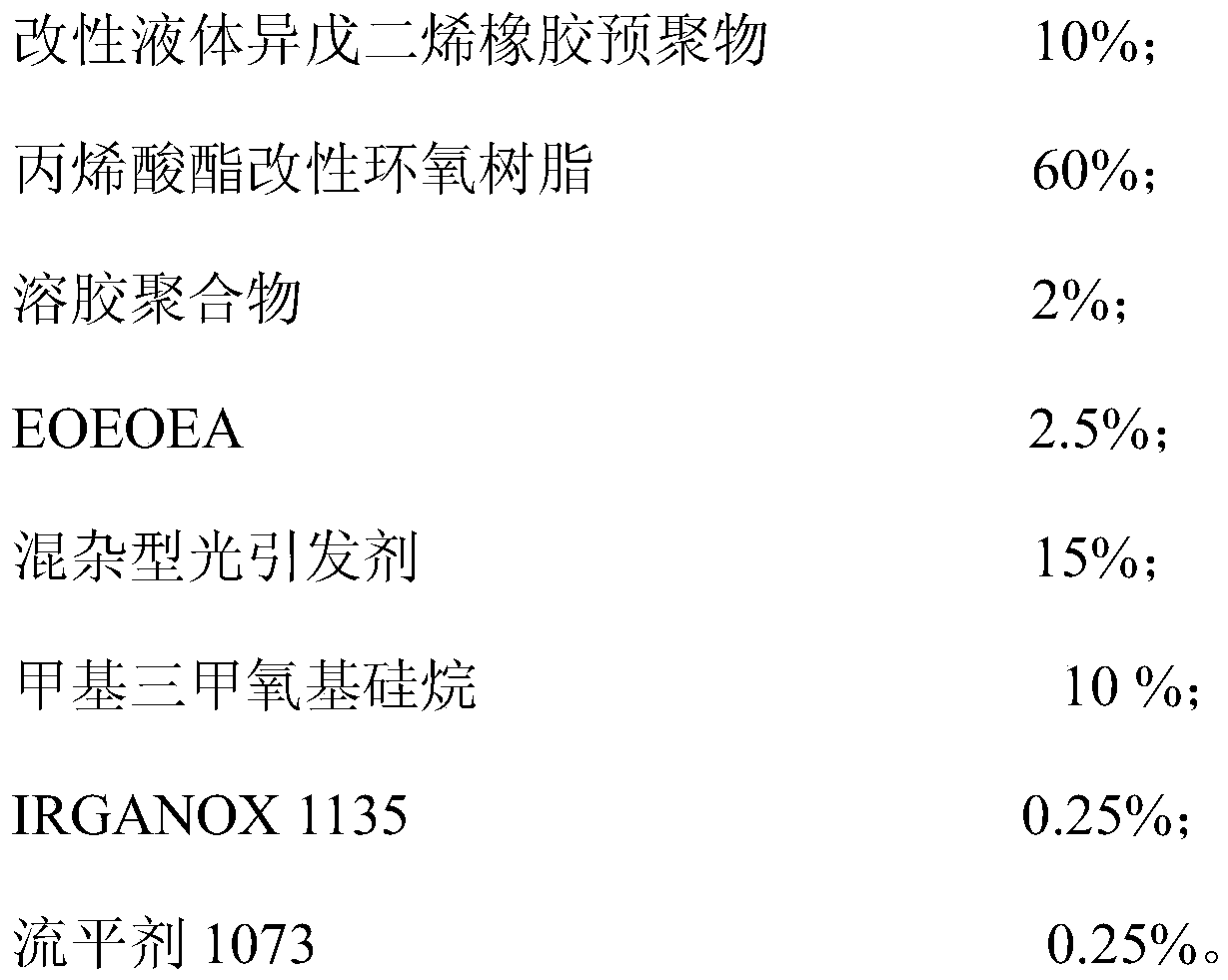

[0039] Liquid optical glue for full lamination, calculated by weight percentage, its components are:

[0040]

[0041] Among them, the hybrid photoinitiator is free radical photoinitiator 1173 and cationic initiator alkyliodonium salt, and the mass ratio is 20:1.

[0042] The preparation method of liquid optical adhesive for full lamination comprises the following steps:

[0043] (1) Material dissolution: Weigh the modified liquid isoprene rubber prepolymer, acrylate modified epoxy resin, sol polymer, and EOEOEA monomers according to the above ratio and add them to the reaction kettle. Stir for 1 hour;

[0044] (2) Add hybrid photoinitiator, methyltrimethoxysilane, IRGANOX1135 and leveling agent 1073 to the mixture obtained in step (1) according to the percentage and stir for 2 hours until the mixture is uniform.

[0045] (3) Vacuum defoaming, filtering and discharging the mixture obtained in step (2) to obtain a liquid optical adhesive product for full lamination with a ...

Embodiment 2

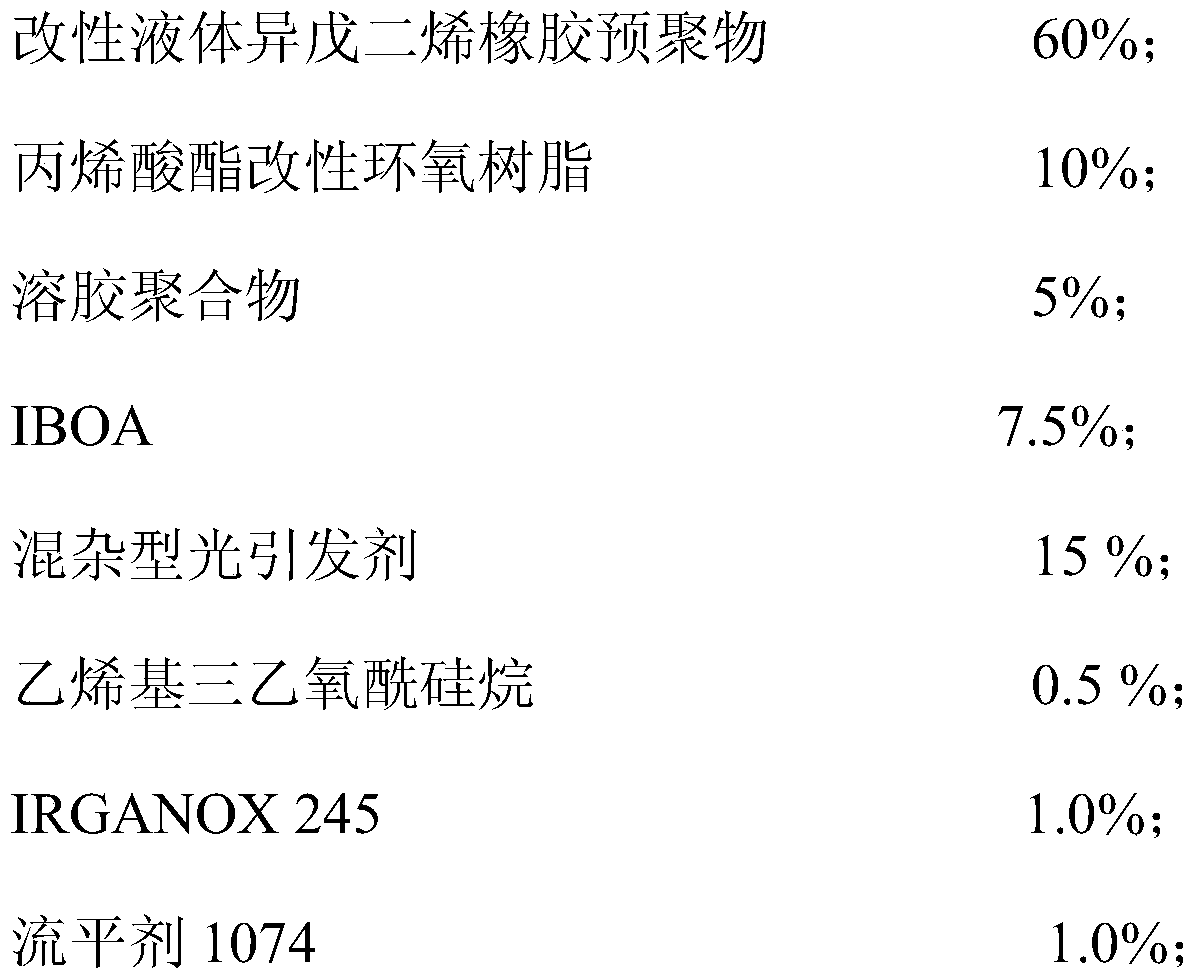

[0048] Liquid optical glue for full lamination, calculated by weight percentage, its components are:

[0049]

[0050] Among them, the hybrid photoinitiator is the free radical photoinitiator 184 and the cationic initiator cumene ferrocene hexafluorophosphate, the mass ratio of which is 5:1.

[0051] The preparation method of liquid optical adhesive for full lamination comprises the following steps:

[0052] (1) Material dissolution: Weigh the monomers of modified liquid isoprene rubber prepolymer, acrylate modified epoxy resin, sol polymer, and IBOA according to the above ratio and add them to the reaction kettle. Stir for 2 hours.

[0053] (2) Add the hybrid photoinitiator, vinyltriethoxysilane, IRGANOX245 and leveling agent 1074 to the mixture obtained in step (1) according to the percentage and stir for 3 hours until the mixture is uniform.

[0054] (3) Vacuum defoaming, filtering and discharging the mixture obtained in step (2) to obtain a liquid optical adhesive pro...

Embodiment 3

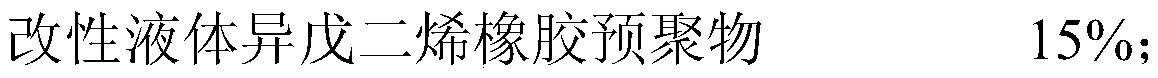

[0057] Liquid optical glue for full lamination, calculated by weight percentage, its components are:

[0058]

[0059]

[0060] Wherein, the hybrid photoinitiator is free radical photoinitiator 184: cationic initiator alkyliodonium salt, the mass ratio of which is 10:1.

[0061] The preparation method of liquid optical adhesive for full lamination comprises the following steps:

[0062] (1) Material dissolution: Weigh the modified liquid isoprene rubber prepolymer, acrylate modified epoxy resin, sol polymer, and EOEOEA monomers according to the above ratio and add them to the reaction kettle. Stir for 2 hours.

[0063] (2) According to the percentage, add hybrid photoinitiator, r-mercaptopropyltrimethoxysilane, IRGANOX565 and leveling agent 1073 to the mixture obtained in step (1) and stir for 2 hours until the mixture is uniform.

[0064] (3) Vacuum defoaming, filtering and discharging the mixture obtained in step (2) to obtain a liquid optical adhesive product for fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cure shrinkage | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| cure shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com