Inorganic conditioner using production wastewater in starch industry and preparation method of conditioner

A technology of inorganic conditioner and soil conditioner, which is applied in the direction of plant growth regulators, botany equipment and methods, chemicals for biological control, etc., can solve the problems of low preparation cost and single function of conditioner, and achieve The preparation cost is low, the application effect is good, and the effect of promoting rooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

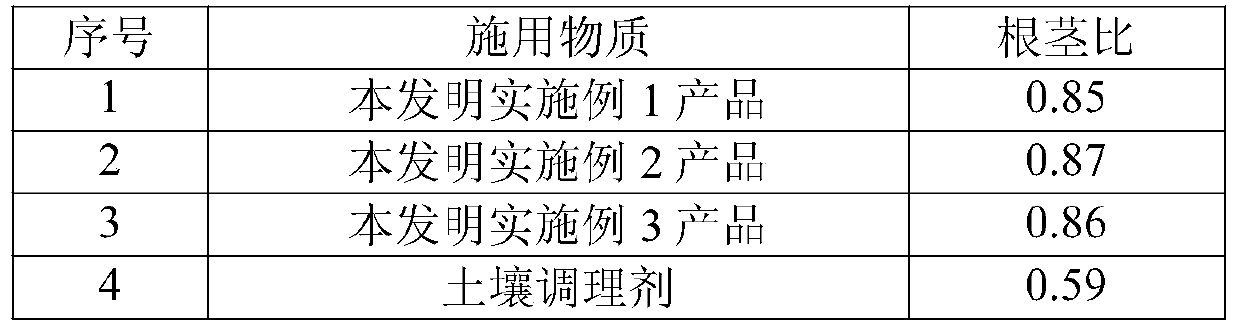

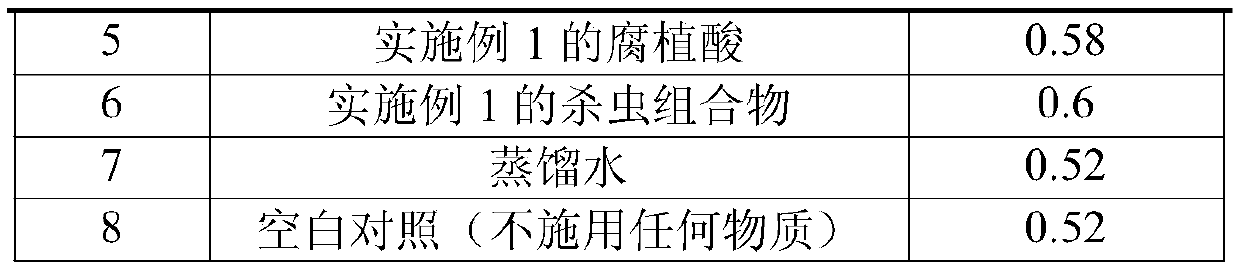

Examples

Embodiment 1

[0047]The invention discloses an inorganic conditioner for waste water produced by starch industry, which comprises the following raw materials in parts by weight: 70 parts of soil conditioner, 50 parts of humic acid, 15 parts of distilled water and 0.6 part of insecticidal composition.

[0048] The soil conditioner comprises: 25 parts of bentonite, 25 parts of kaolin, 10 parts of diatomite and 10 parts of gypsum.

[0049] The preparation method of the inorganic conditioning agent utilizing starch industry to produce waste water, comprises the following steps:

[0050] S1: Set aside to clarify the wastewater from the starch industry to obtain a supernatant, then heat the supernatant to 92°C for evaporation and concentration until the pH value is 3, stop heating, let it stand for activation at room temperature for 10 hours, and then add Adjust the pH value to 5.6 with ammonium carbonate to obtain humic acid liquid, dry the humic acid liquid at 90°C until the water content is 8%...

Embodiment 2

[0054] The invention discloses an inorganic conditioner for waste water produced by starch industry, which comprises the following raw materials in parts by weight: 80 parts of soil conditioner, 60 parts of humic acid, 20 parts of distilled water, and 0.8 part of an insecticidal composition.

[0055] The soil conditioner comprises: 25 parts of bentonite, 25 parts of kaolin, 15 parts of diatomite and 15 parts of gypsum.

[0056] The preparation method of the inorganic conditioning agent utilizing starch industry to produce waste water, comprises the following steps:

[0057] S1: Set aside to clarify the starch industry wastewater to obtain a supernatant, then heat the supernatant to 94°C for evaporation and concentration, concentrate to a pH value of 2, stop heating, stand at room temperature for 8 hours, and then add Adjust the pH value to 5.8 with ammonium carbonate to obtain humic acid liquid, dry the humic acid liquid at 100°C until the water content is 6%, crush it and pas...

Embodiment 3

[0061] The invention discloses an inorganic conditioner for waste water produced by starch industry, which comprises the following raw materials in parts by weight: 75 parts of soil conditioner, 55 parts of humic acid, 18 parts of distilled water and 0.7 part of insecticidal composition.

[0062] The soil conditioner comprises: 25 parts of bentonite, 25 parts of kaolin, 13 parts of diatomite and 12 parts of gypsum.

[0063] The preparation method of the inorganic conditioning agent utilizing starch industry to produce waste water, comprises the following steps:

[0064] S1: Set aside to clarify the starch industry wastewater to obtain a supernatant, then heat the supernatant to 93°C for evaporation and concentration until the pH value is 2.6, stop heating, stand at room temperature for 9 hours, and then add Adjust the pH value to 5.6 with ammonium carbonate to obtain a humic acid solution, dry the humic acid solution at 95°C until the water content is 5%, crush it and pass it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com