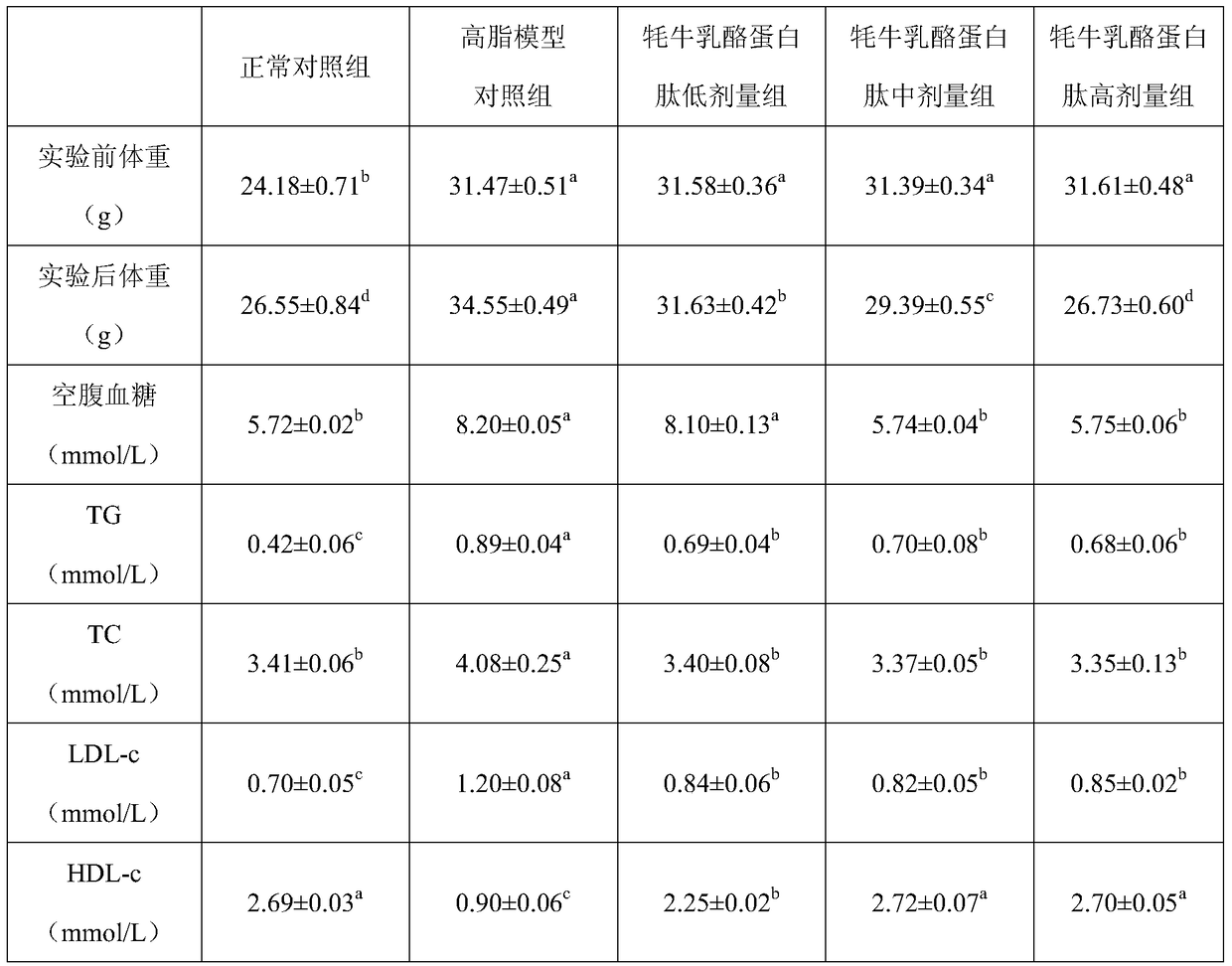

Casein hypoglycemic and lipid-lowering peptide based on yak milk koji and its preparation method and application

A technology for lowering blood sugar and lipids, curd cheese, applied in the direction of application, protein-containing food ingredients, peptides, etc., can solve the problems of reducing biological activity, loss of protein and polypeptide functional components, and burnt odor, etc., to improve gastrointestinal Stability, increase in hydrolysis degree, effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1) Weigh 10 g of yak milk koji crushed to 60 mesh, add 200 mL of water at 40°C and soak for 3 hours to obtain the yak milk koji aqueous solution; treat the yak milk koji aqueous solution for 20 minutes under the conditions of a pressure of 300 MPa and a temperature of 50°C , adjust its pH to 5, and stir for 30 minutes; then, under the condition of a rotating speed of 4000r / min, centrifuge for 20 minutes, collect the supernatant and filter, collect the filtrate, and obtain a yak milk kojira casein solution;

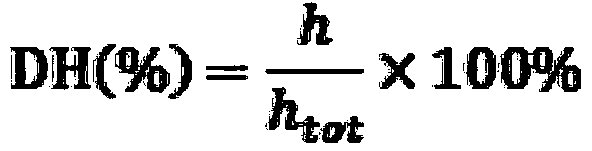

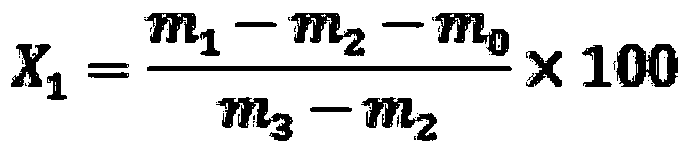

[0027] 2) Adjust the pH of the yak milk kojira casein solution to 2.0, add 50KU of pepsin, and carry out the enzymolysis reaction in a water bath at 40°C for 1 hour; adjust the pH of the enzymolysis reaction system to 7.0, add 50KU of trypsin, and continue the hydrolysis After 2 hours, the temperature of the reaction system was raised to 85°C, kept for 10 minutes, and the reaction was terminated by inactivating the enzyme to obtain a hydrolyzate of yak milk kojira ca...

Embodiment 2

[0046] 1) Weigh 10 g of yak milk koji crushed to 60 mesh, add 200 mL of water at 40°C and soak for 3 hours to obtain the yak milk koji aqueous solution; treat the yak milk koji aqueous solution for 20 minutes at a pressure of 350 MPa and a temperature of 50°C , adjust its pH to 5.5, and stir for 30 minutes; then, under the condition of a rotating speed of 4000r / min, centrifuge for 20 minutes, collect the supernatant and filter, collect the filtrate, and obtain a yak milk kojira casein solution;

[0047] 2) Adjust the pH of the yak milk koji casein solution to 3.0, add 80KU of pepsin, and carry out the enzymolysis reaction in a water bath at 45°C for 1 hour; adjust the pH of the enzymolysis reaction system to 6.0, add 60KU of trypsin, and continue the hydrolysis After 1.5 hours, the temperature of the reaction system was raised to 85°C, kept for 10 minutes, and the reaction was terminated by inactivating the enzyme to obtain a hydrolyzate of yak milk kojira casein. The degree of...

Embodiment 3

[0051] 1) Weigh 10 g of yak milk koji crushed to 60 mesh, add 200 mL of water at 45°C and soak for 1.5 hours to obtain the yak milk koji aqueous solution; process the yak milk koji aqueous solution at an ultrasonic power of 1500W and a temperature of 40°C After 20 minutes, adjust the pH to 6.5, and stir for 50 minutes; then, centrifuge for 20 minutes at a speed of 4000 r / min, collect the supernatant, filter, and collect the filtrate to obtain a yak milk kojira casein solution;

[0052] 2) Adjust the pH of the yak milk koji casein solution to 2.5, add 100KU of pepsin, and carry out the enzymolysis reaction in a water bath at 40°C for 0.5h; adjust the pH of the enzymolysis reaction system to 7.0, add 80KU of trypsin, and continue After hydrolysis for 1 hour, the temperature of the reaction system was raised to 85° C., kept for 10 minutes, and the enzyme was inactivated to terminate the reaction to obtain a hydrolyzate of yak milk kojira casein. The degree of hydrolysis of the enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com