Nickel/zirconia catalyst and its preparation method and method for preparing synthesis gas

A catalyst and nickel salt technology, applied in the field of autothermal reforming of methane to prepare synthesis gas, can solve the problems of high cost, uneven dispersion of nickel components, complicated preparation process of nickel-based catalyst, etc., and achieve reduced preparation cost and excellent catalytic performance. , good catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

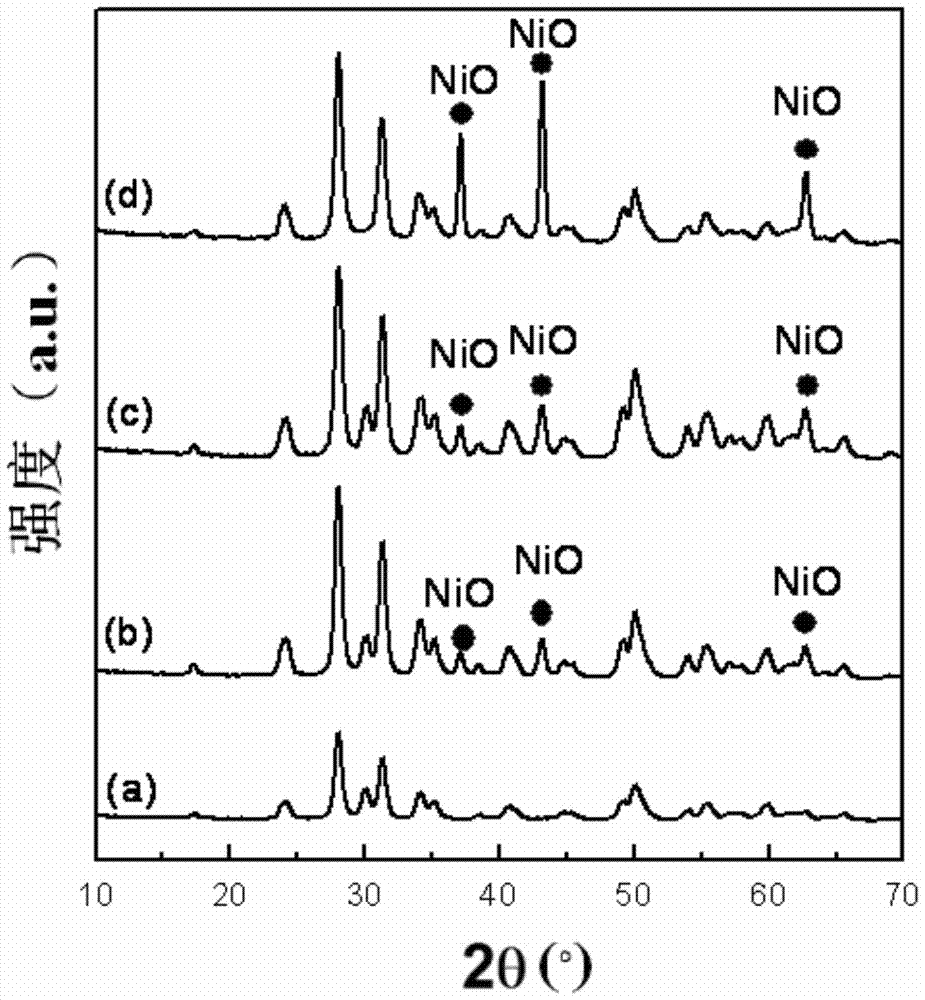

Image

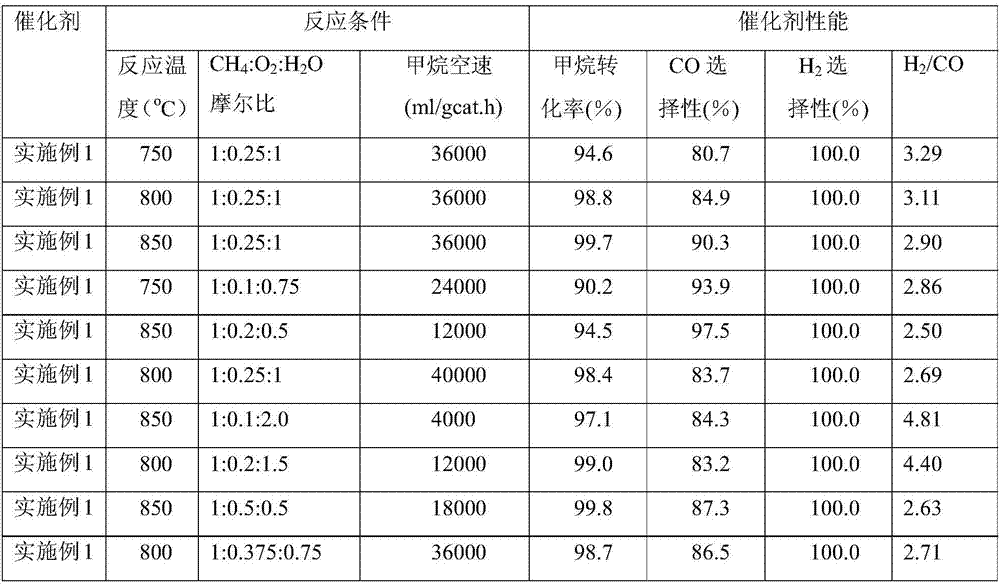

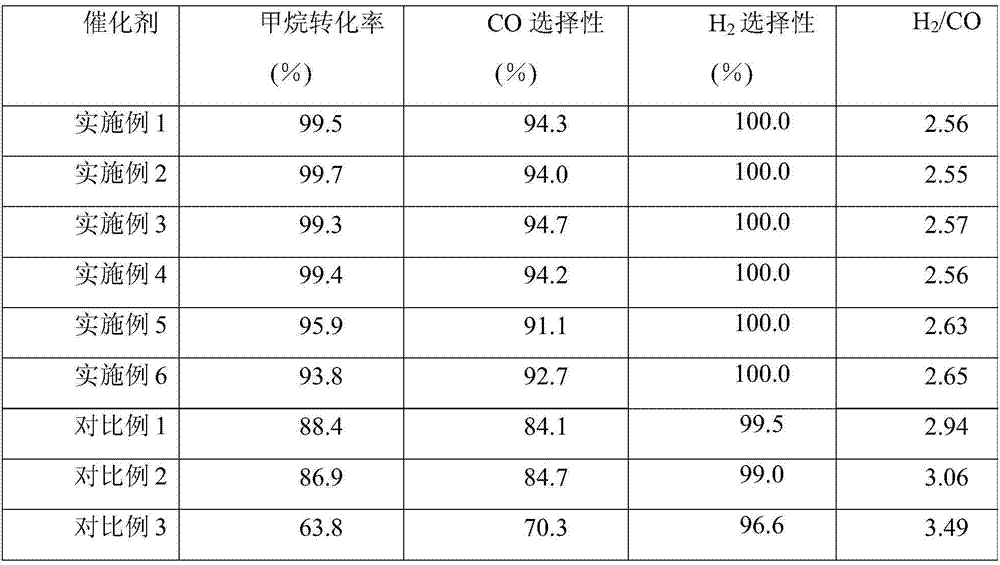

Examples

preparation example Construction

[0023] In a first aspect, the present invention provides a Ni / ZrO 2 The preparation method of catalyst, this method comprises the following steps:

[0024](1) prepare zirconium salt microemulsion, nickel salt microemulsion and alkaline microemulsion respectively;

[0025] (2) In the presence of ultrasonic waves, zirconium salt microemulsion, nickel salt microemulsion and alkaline microemulsion are mixed;

[0026] (3) The system obtained by mixing step (2) is subjected to solid-liquid separation to obtain a solid product, and the solid product is cleaned, dried and roasted to obtain Ni / ZrO 2 catalyst.

[0027] Ni / ZrO of the present invention 2 In the preparation method of catalyst, in step (1), the method for preparing zirconium salt microemulsion, nickel salt microemulsion and alkaline microemulsion is not particularly limited, as long as zirconium salt microemulsion, nickel salt microemulsion and alkali can be prepared The method of preparing zirconium salt microemulsion,...

Embodiment 1

[0051] This embodiment is used to illustrate Ni / ZrO of the present invention 2 Catalyst and method for its preparation.

[0052] 80g of cetyltrimethylammonium bromide, 640g of n-hexane and 200g of n-butanol were mixed to prepare 672ml of microemulsion mixture and evenly divided into three parts. Add 70ml of 1.8mol / L zirconium oxychloride aqueous solution to the first microemulsion mixture to form 294ml zirconium salt microemulsion; add 60ml of 0.5mol / L nickel nitrate aqueous solution to the second microemulsion mixture , Form 284ml nickel salt microemulsion; Add the 1.0mol / L ammonia solution of 180ml in the 3rd part microemulsion mixed solution, form 404ml ammonia water microemulsion.

[0053]With the assistance of ultrasonic waves with a power of 200W, the temperature of the system was maintained at 50°C, and under the condition of continuous stirring at 600rpm, 294ml of zirconium salt microemulsion and 284ml of nickel salt microemulsion were simultaneously added dropwise to...

Embodiment 2

[0056] This embodiment is used to illustrate Ni / ZrO of the present invention 2 Catalyst and method for its preparation.

[0057] 80g of octadecyltrimethylammonium bromide, 320g of cyclohexane and 320g of n-hexanol were mixed to prepare 510ml of microemulsion mixture and evenly divided into three parts. Add the 0.6mol / L zirconium nitrate aqueous solution of 94ml in the first part of microemulsion mixed solution, form 264ml zirconium salt microemulsion; Add the 0.2mol / L nickel chloride aqueous solution of 113ml in the second part of microemulsion mixed solution, Form 283ml of nickel salt microemulsion; Add 53ml of 2.0mol / L ammonia solution to the third part of microemulsion mixture to form 223ml of ammonia water microemulsion.

[0058] With the assistance of ultrasonic waves with a power of 150W, the temperature of the system was maintained at 80°C, and under the condition of continuous stirring at 700rpm, 264ml of zirconium salt microemulsion and 283ml of nickel salt microemul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com