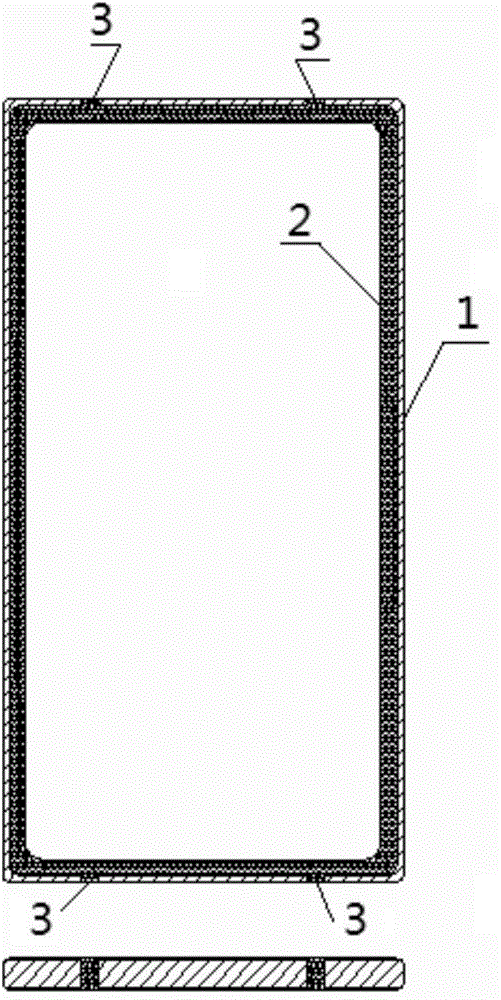

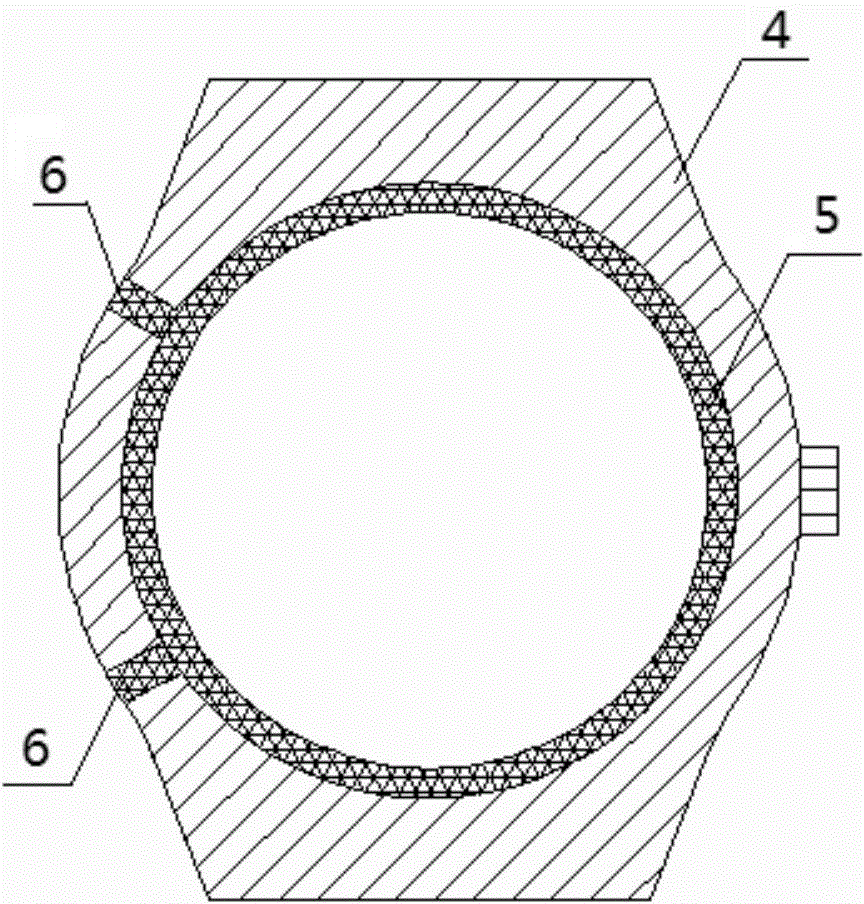

Metal base subjected to surface treatment, metal-resin compound, preparation methods and uses of metal-resin compound and metal base subjected to surface treatment, electronic product housing and preparation method of electronic product housing

A metal substrate and surface treatment technology, applied in the direction of metal layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problem of low bonding strength between the metal substrate and the resin layer, and achieve high bonding strength, The effect of high structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0110] (1) A commercially available 5052 aluminum alloy plate with a thickness of 1 mm was cut into rectangular pieces of 15 mm×80 mm. Put the rectangular piece into the polishing machine for polishing. Then, it was washed with absolute ethanol, then immersed in an aqueous solution of sodium hydroxide with a concentration of 2% by weight, taken out after 2 minutes, and rinsed with deionized water to obtain a pretreated aluminum alloy sheet.

[0111] (2) putting the aluminum alloy sheet that step (1) obtains as anode into a micro-arc oxidation tank with a concentration of 20% by weight sodium silicate aqueous solution as an electrolyte, and using a graphite carbon plate as a cathode, under a voltage of 100V , electrolyzed at 20°C for 30 minutes for micro-arc oxidation. The aluminum alloy sheet subjected to micro-arc oxidation is taken out and dried to obtain an aluminum alloy sheet with a micro-arc oxidation film layer on the surface. The cross-section of the aluminum alloy s...

Embodiment 2

[0117] The same method as in Example 1 is used to carry out surface treatment on the aluminum alloy sheet and prepare a metal-resin composite body. The difference is that in step (2), the electrolyte used is a sodium phosphate aqueous solution with a concentration of 20% by weight, and the voltage is 80V, the temperature of the electrolyte is 20°C.

[0118] Observe the cross-section of the aluminum alloy sheet obtained in step (2) with a microscope, and determine that the average thickness of the micro-arc oxidation film layer is 15 μm. Adopt the cross-section of the aluminum alloy plate that microscope observation step (3) obtains, find: in the micro-arc oxidation film layer, be distributed with the corrosion hole that aperture is in the scope of 50-200nm, the depth of this corrosion hole and the thickness of micro-arc oxidation film layer The ratio is in the range of 0.3-1:1, and the ratio of the depth of the corrosion hole to the thickness of the micro-arc oxidation film la...

Embodiment 3

[0121] The aluminum alloy sheet was surface treated and a metal-resin composite was prepared using the same method as in Example 1, except that in step (3), the etching solution was an aqueous solution of NaOH (pH=13).

[0122] Adopt the cross-section of the aluminum alloy plate that microscope observation step (3) obtains, find: in the micro-arc oxidation film layer, be distributed with the corrosion hole that aperture is in the range of 10-200nm, the depth of this corrosion hole and the thickness of micro-arc oxidation film layer The ratio is in the range of 0.1-1:1, and the ratio of the depth of the corrosion hole to the thickness of the micro-arc oxidation film layer is 1:1 in more than 50% of the corrosion holes.

[0123] The average shear strengths of the prepared metal-resin composites are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com