Power compensation type workover rig power transmission system

A technology of power transmission system and power compensation, applied in mechanical equipment, spring mechanism, fluid pressure actuating device, etc., can solve problems such as poor matching and inability to provide constant pressure, so as to improve energy storage density and shorten charging energy. effect of time, volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

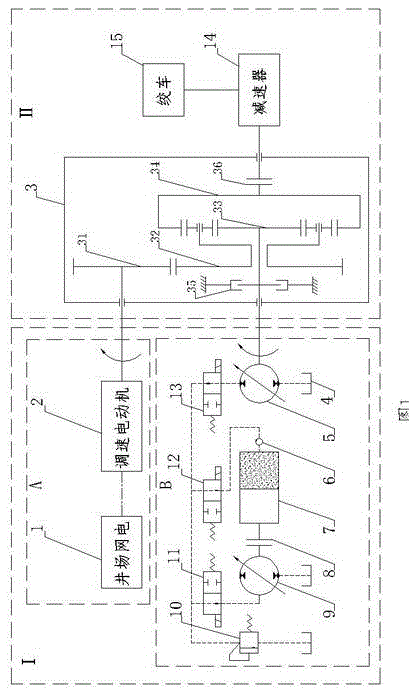

[0024] see figure 1 , in the power system A, the well site network power 1 drives the speed-adjusting motor 2 through a circuit connection, and inputs the power; It is connected with the speed reducer 14, and the sun gear 33 is connected with the variable pump-motor 5 through the locker 35, so as to realize the charging of the energy storage system B or the joint energy supply of the overall power system I; in the energy storage system B, the variable pump- The motor 5 is connected to the variable pump-motor 9 through the first electromagnetic switch valve 11 and the third electromagnetic switch valve 13, and the variable pump-motor 9 is connected to the flywheel hydraulic accumulator 7 through the clutch 8 to realize the mechanical path connection. The other end of the accumulator 7 is connected to the variable pump-motor 5 through the high-speed rotary joint 6, the second electromagnetic switch valve 12, and the third electromagnetic sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com