Humidity sensor based on stannic oxide/graphene-like molybdenum disulfide film

A technology of humidity sensor and molybdenum disulfide, which is applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of sensor inapplicability, high power consumption, hysteresis, etc., and achieve the effect of effective real-time monitoring and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

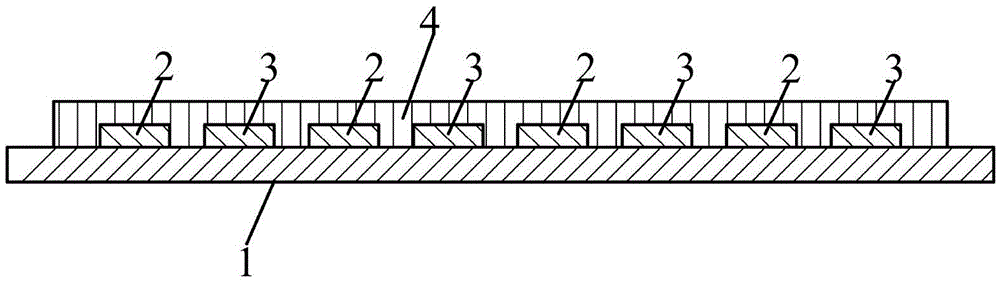

[0019] see figure 1 , the embodiment of the present invention is provided with a polyethylene terephthalate substrate 1, a first electrode 2 of a meander-shaped interdigital electrode, a second electrode 3 of a meander-shaped interdigitated electrode, a tin dioxide / graphene-like electrode Molybdenum sulfide film 4.

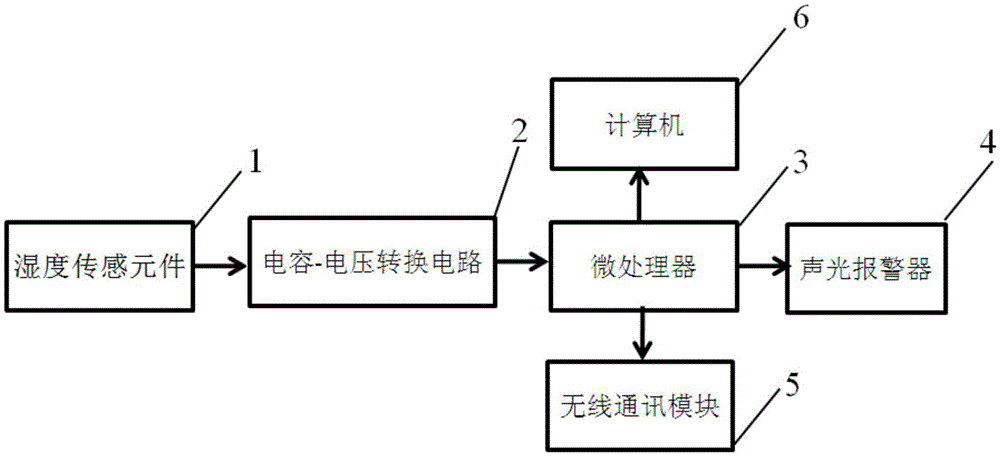

[0020] see figure 2 , the present invention is implemented and applied to the detection of environmental humidity, 1 is a humidity sensing element based on tin dioxide / graphene-like molybdenum disulfide film, 2 is a capacitance-voltage conversion circuit, 3 is a STM32F103 microprocessor, and 4 is acousto-optical Alarm, 5 is the SI4432 wireless communication module, 6 is the computer, the humidity detection of the environment is realized by detecting the capacitance change of the humidity sensing element 1, and it has the functions of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap