Disordered netty carbon nanotube based p-n junction diode and preparation method thereof

A carbon nanotube and carbon nanotube film technology, which is applied in the field of p-n junction diodes and their preparation, can solve problems such as complex processes, and achieve the effects of stable performance and excellent rectification characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

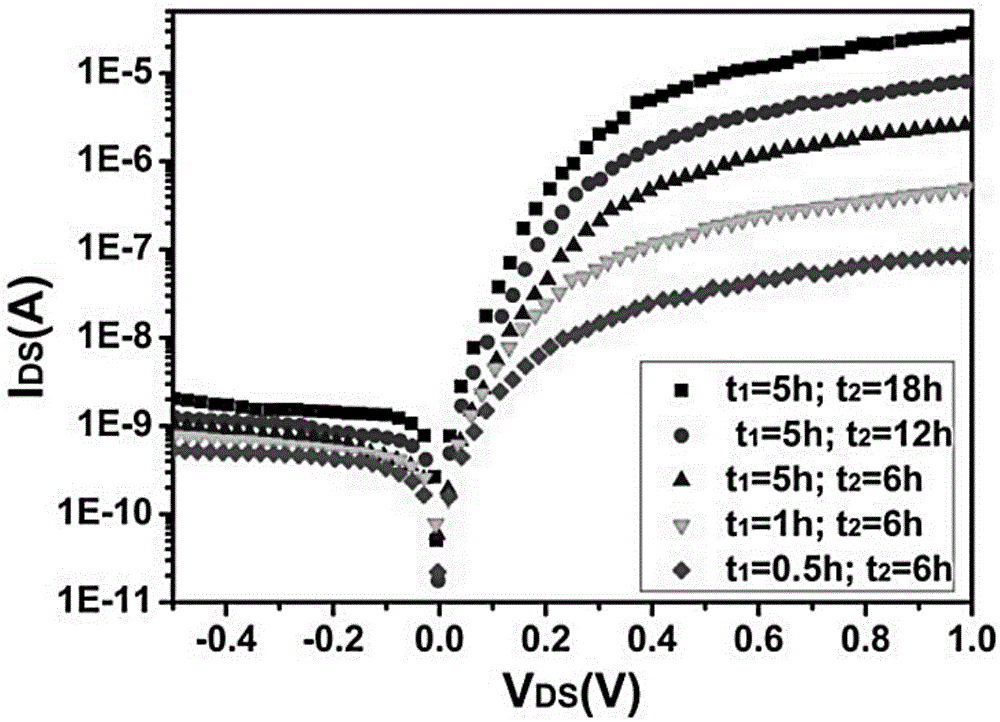

[0027] This embodiment includes the following steps:

[0028] The first step is to use electrostatic self-assembly technology to self-assemble a layer with a density of 1.5 μm on the surface of the silicon wafer -2 disordered carbon nanotube films.

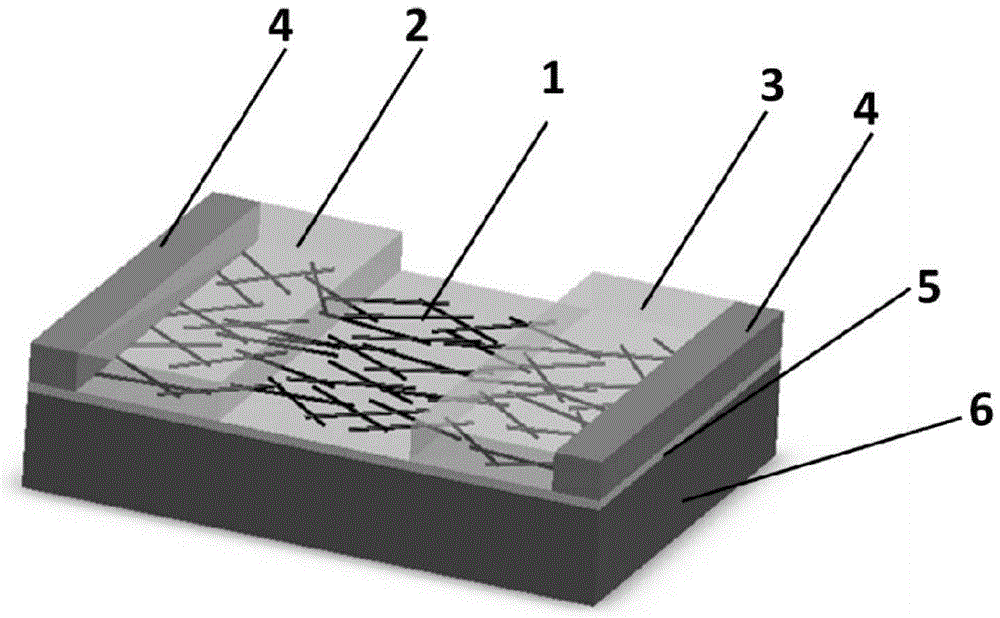

[0029] In the second step, Au symmetric electrodes (such as figure 1 ), the electrode width is 5 μm, and the distance between opposite electrodes is 6 μm.

[0030] In the third step, the excess carbon nanotubes beside the channel of the amorphous network carbon nanotubes are etched away by ion etching technology.

[0031] In the fourth step, the electron beam photoresist is coated on the substrate, and one end of the disordered network carbon nanotube is exposed by opening a window with a window size of 5 μm*3 μm by using the electron beam lithography technique. The exposed end of the disordered network carbon nanotube channel will be exposed to the air after being developed and fixed. The unexposed end will be protected by ph...

Embodiment 2

[0036] This embodiment includes the following steps:

[0037] The first step is to use electrostatic self-assembly technology to self-assemble a layer with a density of 1.5 μm on the surface of the silicon wafer -2 disordered carbon nanotube films.

[0038] In the second step, electron beam lithography and magnetron sputtering techniques are used to fabricate Au symmetrical electrodes at both ends of the carbon nanotubes, with an electrode width of 5 μm and a distance between opposite electrodes of 6 μm.

[0039] In the third step, the excess carbon nanotubes beside the channel of the disordered network carbon nanotubes are etched away by ion etching technology.

[0040] In the fourth step, the electron beam photoresist is coated on the substrate, and one end of the carbon nanotube is exposed to a window by using the electron beam lithography technology, and the window size is 5 μm*2 μm. The exposed portion (5 μm*2 μm) of the disordered network carbon nanotube channel will b...

Embodiment 3

[0044] This embodiment includes the following steps:

[0045] The first step is to use electrostatic self-assembly technology to self-assemble on the surface of silicon wafers with a density of 1.5 μm -2 disordered carbon nanotube films.

[0046] In the second step, electron beam lithography and magnetron sputtering techniques are used to fabricate Au symmetrical electrodes at both ends of the carbon nanotubes, with an electrode width of 5 μm and a distance between opposite electrodes of 6 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com