Transition metal oxide p-n hetero-junction and preparation method thereof

A transition metal and heterojunction technology, applied in metal material coating process, semiconductor/solid-state device manufacturing, ion implantation plating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

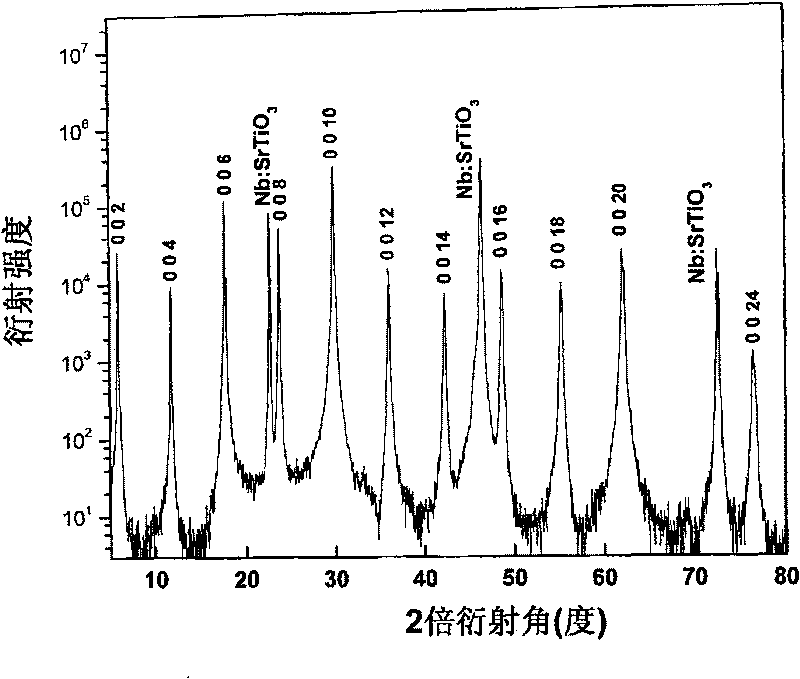

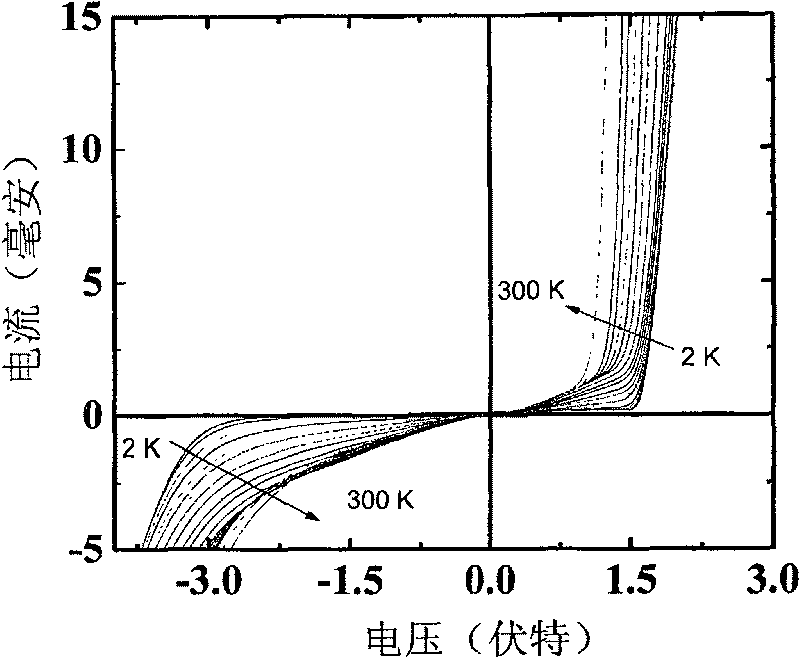

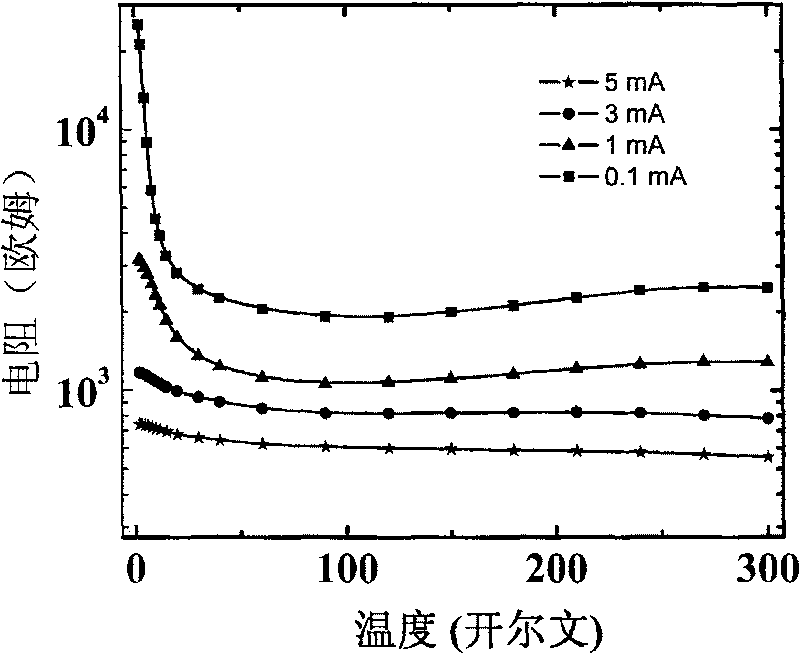

[0028] Example 1: Bi 2 Sr 2 co 2 o 8 (100nm) / Sr 0.093 Nb 0.007 TiO 3 Fabrication of p-n heterojunctions.

[0029] 1. Bi-rich bismuth strontium cobalt oxide (Bi 21 Sr 2 co 2 o 8 ) Sintering of ceramic targets;

[0030] a. Bi with a purity of 99.95% 2 o 3 , SrCO 3 and Co 3 o 4 Powder by Bi 21 Sr 2 co 2 o 8 Chemical proportion weighing;

[0031] b. Mix the above powders evenly and grind them in a ball mill for 5 hours;

[0032] c. Put the ground powder in an alumina crucible, and then put it into a high-temperature furnace for sintering. The sintering temperature is 700°C and the time is 3 hours;

[0033] d, the sintered powder is taken out, placed in a ball mill and ground for 3 hours, then pressed into a small round cake with a diameter of 25 cm with a tablet press, and the weight of the small round cake is 12 grams. Finally, the small round cake is sintered in a high-temperature furnace at a temperature of 880° C. for 10 hours.

[0034] 2. The Bi-rich b...

Embodiment 2

[0041] Example 2: Bi 2 Sr 2 co 2 o 8 (20nm) / Sr 0.09 Nb 0.01 TiO 3 Fabrication of p-n heterojunctions.

[0042] 1. Repeat steps 1-2 in Example 1;

[0043] 2. Doping niobium into 1% doped strontium niobate titanate (Sr 0.093 Nb 0.01 TiO 3 ) substrate (place of origin: Hefei Kejing Material Technology Co., Ltd.) is ultrasonically cleaned with acetone, alcohol, and deionized water with a purity of 99.99%, and then placed on the heater in the reaction chamber;

[0044] 3. Repeat steps 4-5 in Example 1;

[0045] 4. Remove the base baffle and start formal deposition. The deposition time is 1 minute. The laser frequency during deposition is 4Hz, and the energy density is 1.5×10 4 J / m 2 ;

[0046] 5. Repeat step 7 in Example 1;

[0047] 6. After the substrate temperature drops to 30°C, take the sample out of the pulsed laser deposition reaction chamber. In this way, a p-type conductive bismuth strontium cobalt oxide (Bi 2 Sr 2 co 2 o 8 ) film and 1% Nb-doped n-type ...

Embodiment 3

[0048] Example 3: Bi 2 Sr 2 co 2 o 8 (200nm) / Sr 009 Nb 0.007 TiO 3 Fabrication of p-n heterojunctions.

[0049] 1. Repeat steps 1-5 in Example 1;

[0050] 2. Remove the substrate baffle and start formal deposition. The deposition time is 10 minutes. The laser frequency during deposition is 4Hz, and the energy density is 1.5×10 4 J / m 2 ;

[0051] 3. Repeat step 7 in Example 1;

[0052] 4. After the substrate temperature drops to 30°C, take the sample out of the pulsed laser deposition reaction chamber. In this way, a p-type conductive bismuth strontium cobalt oxide (Bi 2 Sr 2 co 2 o 8 ) film and 0.7% Nb-doped n-type conductive doped strontium niobate titanate (Sr 0.093 Nb 0.007 TiO 3 ) substrate composed of Bi 2 Sr 2 co 2 o 8 (200nm) / Sr 0.09 Nb 0.007 TiO 3 p-n heterojunction, so far the whole preparation process is over.

[0053] Sintered Bi-rich bismuth strontium cobalt oxide Bi as described in the above examples 2+x Sr 2 co 2 o 8 For ceramic targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com