Gas dilution and mixing system

A mixing system and gas mixing technology, applied in the directions of gas and gas/vapor mixing, mixers, mixing methods, etc., can solve problems such as inability to prepare, and achieve the effects of effective absorption, environmental protection, and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

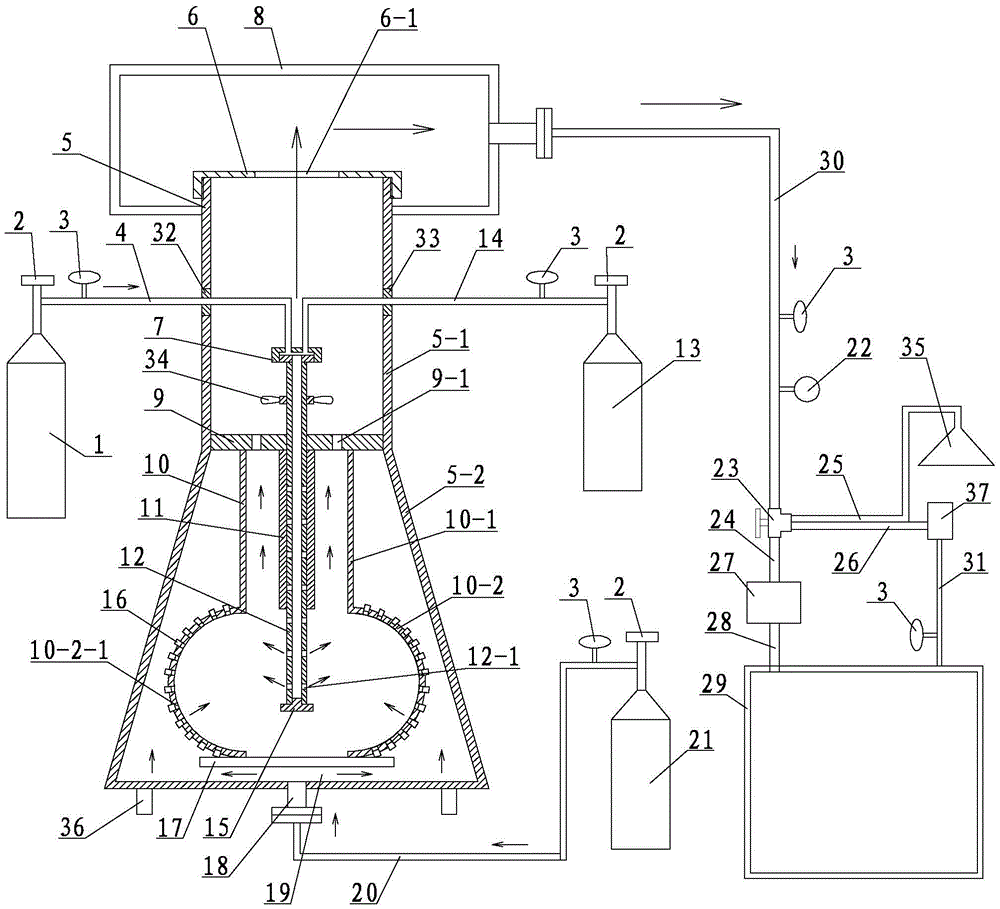

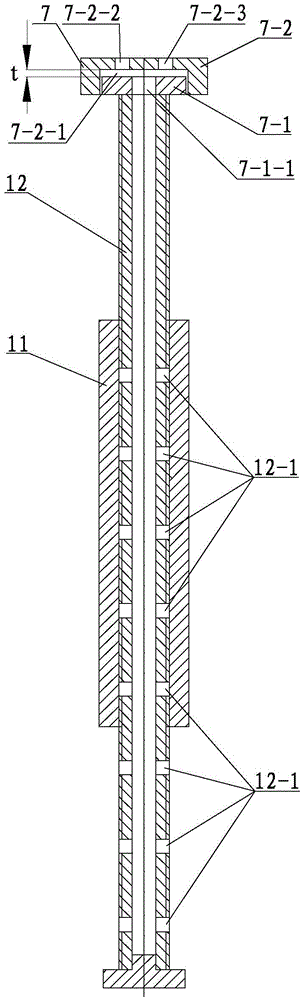

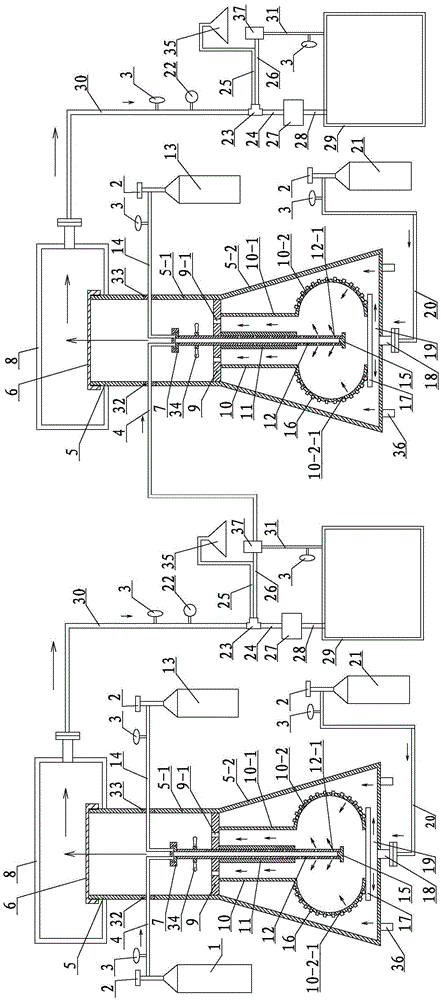

[0018] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, this embodiment includes the first dilution gas cylinder 1, the first dilution gas delivery pipe 4, the gas mixing box 5, the box cap 6, the connector 7, the gas temporary storage box 8, the fixed plate 9, the gas mixing bottle 10. Sleeve 11, threaded pipe 12, bolt plug 15, deflector 17, intake pipe 18, second dilution gas delivery pipe 20, second dilution gas cylinder 21, composite concentration detector 22, three-way valve 23 , storage pipeline 24, gas absorption pipe 25, user connection 26, gas compression drying device 27, storage connection 28, storage 29, connecting pipe 30, delivery pipe 31, gas adsorption device 35, several gas pressure reducers 2, several A flow meter 3 and several plugs 16, the gas mixing box 5 is composed of a circular box 5-1 and a cone box 5-2, the circular box 5-1 and the cone box 5-2 are set up and down, and the fixed plate 9 is horizontally set on...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the inner wall of the gas mixing box 5, the inner and outer walls of the gas mixing bottle 10, the inner and outer walls of the sleeve 11, and the inner and outer walls of the threaded pipe 12 in this embodiment are all coated with a coating. The coating is alumina, titania or zirconia. This design makes the above-mentioned components have anti-corrosion and anti-oxidation functions. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination figure 1 The present embodiment will be described. The gas mixing box 5 of the present embodiment is a two-lobed fastening type. This design can manually adjust the length of the lower end surface of the threaded pipe 12 protruding from the sleeve 11, and control the blocking quantity of the plug 16 on the air inlet hole 10-2-1. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com