High-adsorption-performance micro-crystal bamboo charcoal perlite pottery product and preparation method thereof

A technology of microcrystalline bamboo charcoal and perlite, which is applied in the field of ceramic products, can solve the problems of insufficient function of bamboo charcoal, low flexural strength, low adsorption rate, etc., and achieve high technological content and economic value, high flexural strength, and adsorption strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

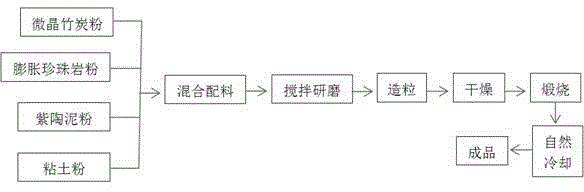

[0030] refer to figure 1 , the preparation method of the microcrystalline bamboo charcoal perlite ceramsite with high adsorption performance of the present invention is:

[0031] (1) Preparation of microcrystalline bamboo charcoal powder: Bamboo wood is carbonized at 400-450°C, activated at 850°C, and finally crystallized at 1200°C in three steps, fired and crushed, with an average particle size of 30 μm, and used for later use;

[0032] (2) Weigh 10 microcrystalline bamboo charcoal powder, 45 expanded perlite powder, 10 clay clay powder and 35 clay clay according to the weight ratio of materials; among them: the average particle size of expanded perlite powder is 30 μm, and the average particle size of purple clay clay powder is 30 μm. The particle size is 10μm,

[0033] (3) Stir and mix the above-mentioned raw materials in proportion, and grind them into mud;

[0034] (4) Put the mixture in step (2) into the granulator for granulation;

[0035] (5) Air-dry naturally, or d...

Embodiment 2

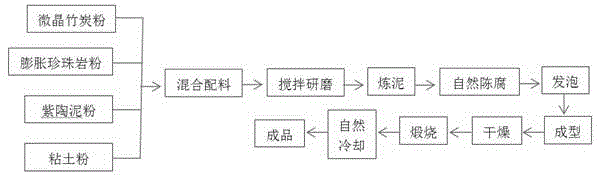

[0039] refer to figure 2 , the preparation method of the microcrystalline bamboo charcoal perlite honeycomb pottery with high adsorption performance of the present invention is:

[0040] (1) Preparation of microcrystalline bamboo charcoal powder: Bamboo is carbonized at 400-450°C, activated at 850°C, and finally crystallized at 1200°C, fired in three steps, crushed, with an average particle size of 70 μm, and set aside;

[0041] (2) Weigh microcrystalline bamboo charcoal powder 20, expanded perlite powder 35, purple clay powder 10, and clay 35 according to the weight ratio of the materials used; among them: the average particle size of expanded perlite powder is 70 μm, and the average particle size of purple clay powder is The particle size is 30μm,

[0042] (3) Stir and mix the above-mentioned raw materials in proportion, and grind them into mud;

[0043] (4) Put the mixture in step (2) into a vacuum mud refiner to refine the mud, leave it for 24 hours to age naturally and...

Embodiment 3

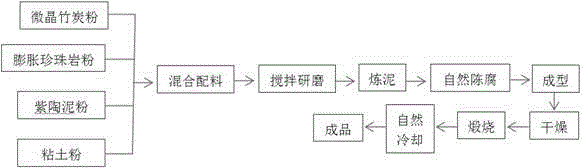

[0048] refer to image 3 , the preparation method of the microcrystalline bamboo charcoal perlite plate pottery with high adsorption performance of the present invention is:

[0049] (1) Preparation of microcrystalline bamboo charcoal powder: Bamboo wood is carbonized at 400-450°C, activated at 850°C, and finally crystallized at 1200°C in three steps, fired and crushed, with an average particle size of 100 μm, and set aside;

[0050] (2) Weigh 30 microcrystalline bamboo charcoal powder, 25 expanded perlite powder, 10 clay clay powder, and 35 clay clay according to the weight ratio of the materials used; among them: the average particle size of expanded perlite powder is 100 μm, and the average particle size of purple clay clay powder is 100 μm. The particle size is 50μm;

[0051] (3) Stir and mix the above-mentioned raw materials in proportion, and grind them into mud;

[0052] (4) Put the mixture in step (2) into a vacuum mud refiner to refine the mud, leave it to age natur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com