A kind of imidazole copper catalyst, preparation method and application

A catalyst, imidazole copper technology, applied in the field of preparation of imidazole copper catalyst, can solve the problem of low activity, achieve the effect of simple preparation method, good catalytic activity, and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

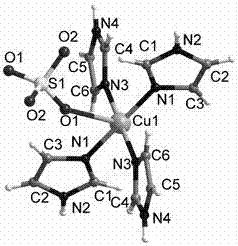

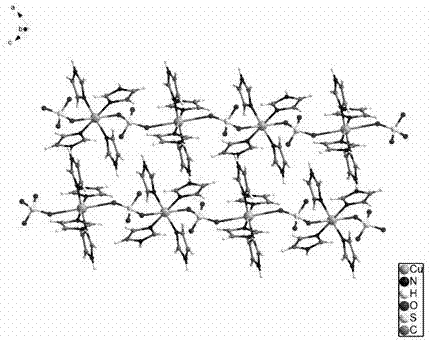

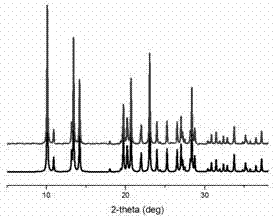

Image

Examples

specific example 1

[0030] Specific example 1: Compound Cu(Im) 4 SO 4 Preparation: In a clean beaker, add carbonyldiimidazole (2.2 mmol), copper sulfate (1 mmol), methanol (400 mmol) and water (100 mmol) successively, heat and stir at 55 degrees Celsius for 2 h, cool, filter, The filtrate was slowly evaporated at room temperature, and block single crystals were obtained after 5-7 days. The yield is about 74%.

specific example 2

[0031] Specific example 2: Compound Cu(Im) 4 SO 4 Preparation: In a clean beaker, add carbonyldiimidazole (2.2 mmol), copper sulfate (1.3 mmol), methanol (400 mmol) and water (100 mmol) successively, heat and stir at 55 degrees Celsius for 2 h, cool and filter, The filtrate was slowly evaporated at room temperature, and block single crystals were obtained after 5-7 days. The yield is about 70%.

specific example 3

[0032] Specific example 3: Compound Cu(Im) 4 SO 4 Preparation: In a clean beaker, add carbonyldiimidazole (2.2 mmol), copper sulfate (1 mmol), methanol (500 mmol) and water (100 mmol) successively, heat and stir at 55 degrees Celsius for 2 h, cool and filter, The filtrate was slowly evaporated at room temperature, and block single crystals were obtained after 5-7 days. The yield is about 71%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com