Method for preparing graphene and graphene composite through reducing graphene oxide at room temperature

A technology for composite materials and graphene, which is applied in the field of preparing graphene and its composite materials by reducing graphene oxide at room temperature, which can solve the problems of difficult removal of impurities and slow reaction, and achieve the effects of low cost, reduced dosage, and avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Disperse 10mg of graphene oxide into 50ml of deionized water, and use ultrasonic dispersion to make it fully dispersed to obtain a graphene oxide dispersion with a concentration of 0.2mg / ml; 10mg of nano-silver and iron tetroxide loaded graphene oxide ternary The composite catalyst was dispersed in 50 ml of deionized water, and ultrasonic dispersion was used to make it fully dispersed to obtain a catalyst dispersion with a concentration of 0.2 mg / ml; then, the graphene oxide dispersion and the catalyst dispersion were uniformly mixed, and it was to be returned Stock solution

[0089] Add 50mg of metal sodium borohydride to the solution to be reduced, sonicate it to make it evenly dispersed, and obtain a concentration of the reducing agent dispersion of 0.5mg / ml, and then stir at room temperature for a reduction reaction for 0.5 hours; after the reduction reaction is over A permanent magnet is used to separate the catalyst from the product suspension, and the product suspen...

Embodiment 2

[0092] Disperse 1mg of graphene oxide and 1mg of nano-silver and ferroferric oxide supported graphene oxide ternary composite catalyst into 100ml of deionized water, and use ultrasonic dispersion to make it fully dispersed to obtain a concentration of 1mg / ml graphene oxide dispersion and Add 5mg of sodium borohydride to the solution to be reduced with a concentration of 1mg / ml graphene oxide dispersion, and ultrasonically disperse it sufficiently to obtain a concentration of the reducing agent dispersion of 0.05mg / ml. Stir at room temperature, the reduction reaction takes place for 0.5 hours; after the reduction reaction, the catalyst is separated from the product suspension with a permanent magnet, and the product suspension is subjected to dialysis treatment to obtain solid graphene

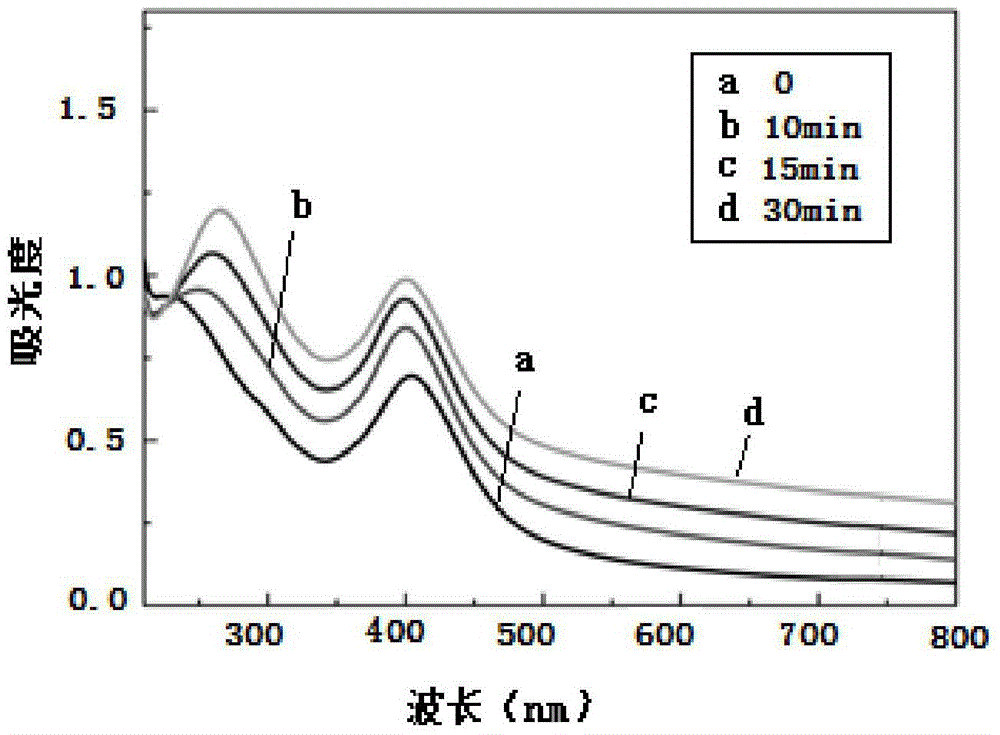

[0093] The characteristic absorption peak of the reaction system is red-shifted from 230 nm of graphene oxide to 272 nm of graphene, and the ultraviolet absorption spectrum is uniformly elevated in...

Embodiment 3、4、6 and 7

[0095] Except for the contents shown in Table 1, graphene was prepared in the same manner as in Example 1.

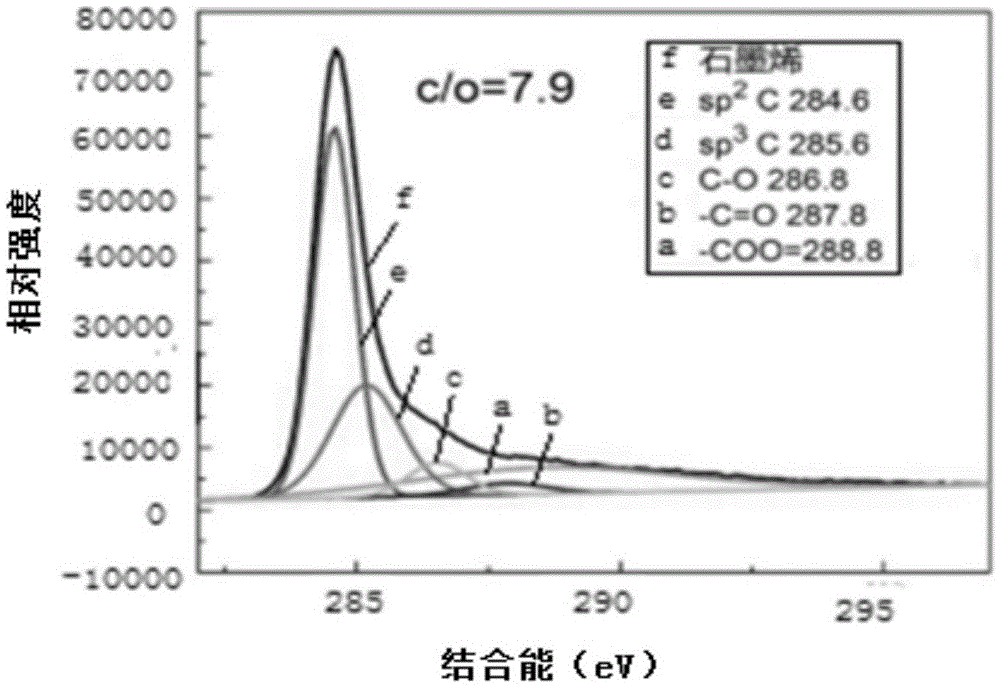

[0096] The characteristic absorption peak of the reaction system is red-shifted from 230 nm of graphene oxide to 272 nm of graphene, and the ultraviolet absorption spectrum is uniformly elevated in the visible region. The resulting graphene has a carbon atom to oxygen atom ratio greater than 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com