Treatment method of fracturing flow-back fluid

A technology of fracturing flowback fluid and treatment methods, which is applied in the fields of filtration treatment, water/sewage treatment, mining wastewater treatment, etc., and can solve problems such as waste of water resources, environmental problems, and complex processes, so as to reduce source waste and reduce costs , the effect of simple processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

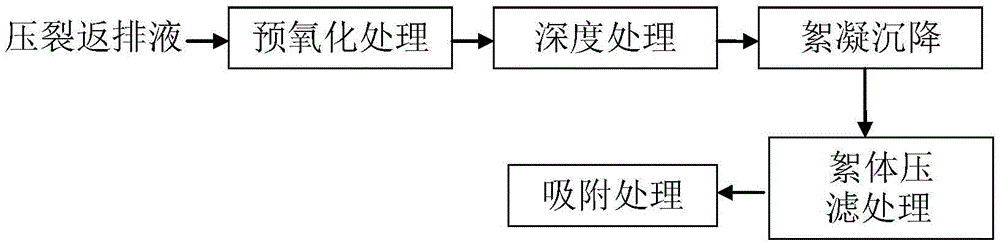

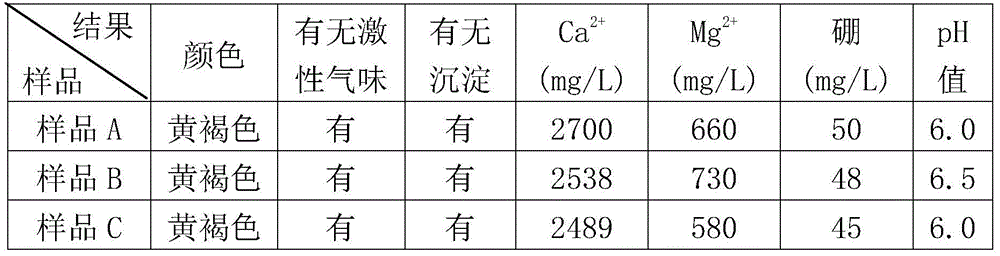

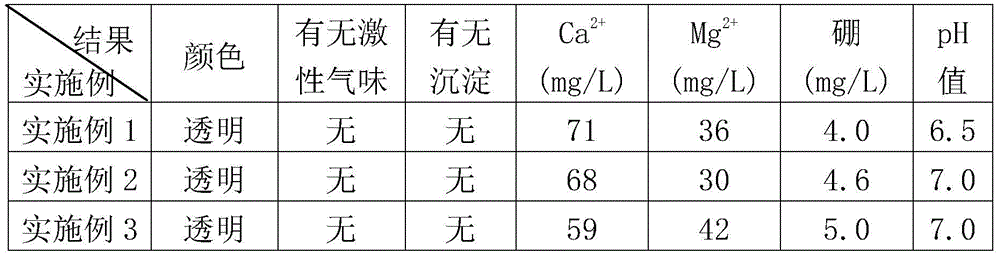

[0024] Take 100L fracturing flowback fluid sample A, and test its water quality. The test results are shown in Table 1. Sample A is processed as follows, wherein the flow chart of the processing process is as follows figure 1 Shown:

[0025] 1) Pre-oxidation treatment: Add 0.2ml of active oxidant hydrogen peroxide to each liter of fracturing flowback fluid, and stir for 3 hours. The active oxidant reduces the chemical oxygen demand of the fracturing flowback fluid and breaks the residual glue in it. The indicators of fracturing flowback fluid before pre-oxidation treatment are shown in Table 1;

[0026] 2) Advanced treatment: Add 3 g of sodium bicarbonate to each liter of fracturing flowback fluid after pre-oxidation treatment, then adjust its pH to 9 with sodium hydroxide, stir for 3 hours, and a white precipitate appears;

[0027] 3) Flocculation and sedimentation: Add 1.5g of polyaluminium chloride and 5mg of cationic polyacrylamide with a molecular weight of 8 million to...

Embodiment 2

[0033] Take 100L fracturing flowback fluid sample B, and test its water quality. The test results are shown in Table 1. Sample B is processed as follows, wherein the flow chart of the processing process is as follows figure 1 Shown:

[0034] 1) Pre-oxidation treatment: add 0.5ml of active oxidant hydrogen peroxide to each liter of fracturing flowback fluid, and stir for 4 hours. The active oxidant reduces the chemical oxygen demand of the fracturing flowback fluid and breaks the residual glue in it. The indicators of fracturing flowback fluid before pre-oxidation treatment are shown in Table 1;

[0035] 2) Advanced treatment: Add 10 g of sodium bicarbonate to each liter of fracturing flowback fluid after pre-oxidation treatment, then adjust its pH to 10 with sodium hydroxide, stir for 3 hours, and a white precipitate appears;

[0036] 3) Flocculation and sedimentation: Add 0.8g of polyaluminum chloride and 10mg of cationic polyacrylamide with a molecular weight of 8 million ...

Embodiment 3

[0042] Take 100L fracturing flowback fluid sample C, and test its water quality. The test results are shown in Table 1. Sample C is processed as follows, wherein the flow chart of the processing process is as follows figure 1 Shown:

[0043] 1) Pre-oxidation treatment: Add 0.8ml of active oxidant hydrogen peroxide to each liter of fracturing flowback fluid and stir for 3 hours. The active oxidant reduces the chemical oxygen demand of the fracturing flowback fluid and breaks the residual glue in it. The indicators of fracturing flowback fluid before pre-oxidation treatment are shown in Table 1;

[0044] 2) Advanced treatment: Add 15g of sodium bicarbonate to each liter of fracturing flowback fluid after pre-oxidation treatment, then adjust its pH to 9 with sodium hydroxide, stir for 4 hours, and a white precipitate appears;

[0045] 3) Flocculation and sedimentation: Add 0.8g of polyaluminum chloride and 17mg of cationic polyacrylamide with a molecular weight of 8 million to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com