Vegetable oil polyhydric alcohol as well as preparation method and application of vegetable oil polyhydric alcohol

A technology of vegetable oil polyol and epoxidized vegetable oil, applied in the preparation of organic compounds, ether preparation, carboxylate preparation and other directions, can solve the problems of low product quality, prone to cross-linking side reactions, and complicated post-processing, etc. Low viscosity, novel structure, and the effect of controlling side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

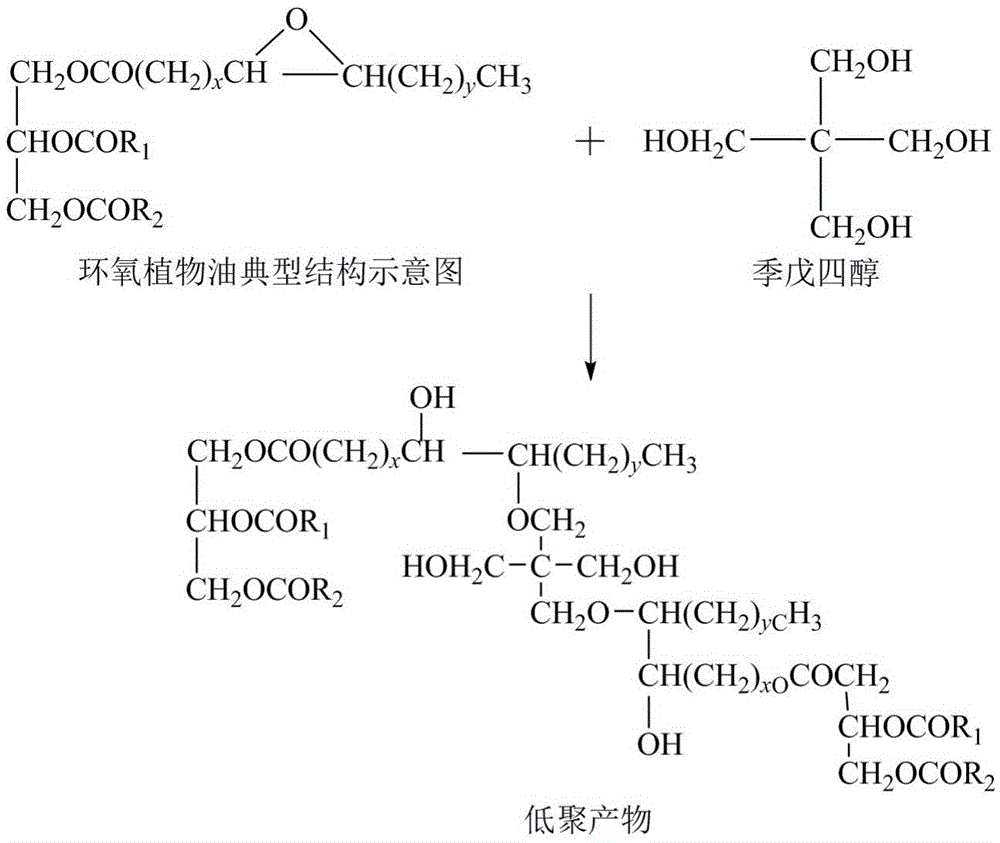

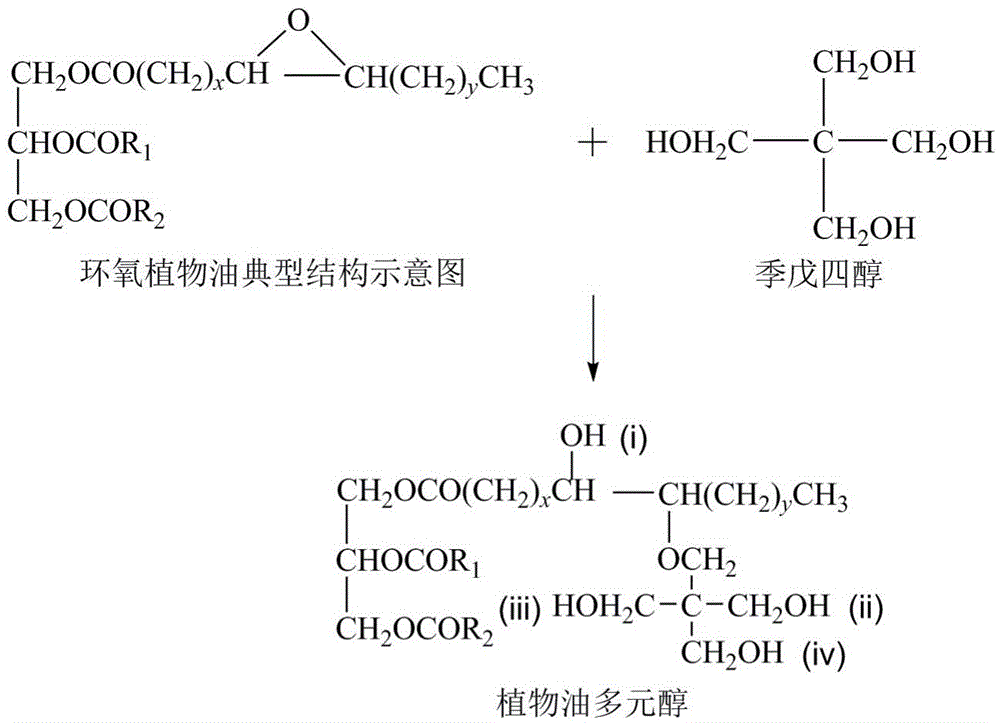

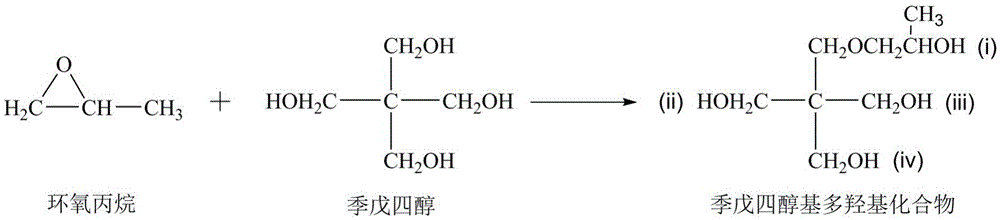

Method used

Image

Examples

Embodiment 1

[0041] Mix 100g epoxidized soybean oil, 75g polyol (the product of the reaction between pentaerythritol and equimolar propylene oxide), and 0.03g sodium methoxide, place it in a conventional kettle-type reactor, feed nitrogen protection, mechanically stir, and heat up to 130°C, stop the reaction after 3 hours of reaction to obtain soybean oil polyol with a hydroxyl value of 561 mgKOH / g and a viscosity of 2950 mPa·s.

Embodiment 2

[0043] Get 100g epoxidized rapeseed oil as component A, and get 0.02g sodium n-butoxide and dissolve it in 55g polyol (the product of the reaction of ethylene glycol with twice the mole of propylene oxide) as component B. Components and B components are pumped into the microchannel modular reaction device at the same time, and the reaction is carried out in the sandwichreactorHC at normal pressure and 130°C. The injection rates of A and B components are 3.0mL / min and 1.6mL / min respectively, keeping The reaction residence time was 8 minutes, and the reaction product was collected to obtain the rapeseed oil polyol with a hydroxyl value of 380 mgKOH / g and a viscosity of 3050 mPa·s.

Embodiment 3

[0045] Get 100g epoxy tung oil as component A, and get 0.02g sodium tert-butoxide and dissolve it in 67g polyol (product of 1,2-propanediol and equimolar propylene oxide reaction) to be component B, mix A, Component B is pumped into the microchannel modular reaction device at the same time, and the reaction is carried out in the Hastelloy microchannel reactor at normal pressure and 140 ° C. The injection rates of A and B components are 1.2 mL / min and 0.8 mL / min, respectively. mL / min, keep the reaction residence time 10min, collect the reaction product to obtain tung oil polyol, its hydroxyl value is 485mgKOH / g, and its viscosity is 2850mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com