High-calcium-aluminum slag ball and preparing method thereof

A technology of aluminum slag balls and high calcium, applied in the direction of improving process efficiency, etc., can solve the problems of unfavorable impurities adsorption, removal, unsatisfactory effect, hidden danger of accidents, etc., to achieve convenient dosing process, increase production rate, and improve fluidity Effect

Inactive Publication Date: 2016-05-04

BEIJING ANTAI YONGSHENG METAL MATERIAL CO LTD

View PDF4 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the common deoxidizing substances are aluminum, calcium, magnesium, silicon, manganese, etc.; if calcium deoxidation is used, the cost will be too high, if magnesium deoxidation is used, accident hazards will easily occur, and silicon, manganese and other substances are used for deoxidation. The effect is not ideal. However, simply using pure aluminum for deoxidation is not conducive to the adsorption and removal of impurities in molten steel.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

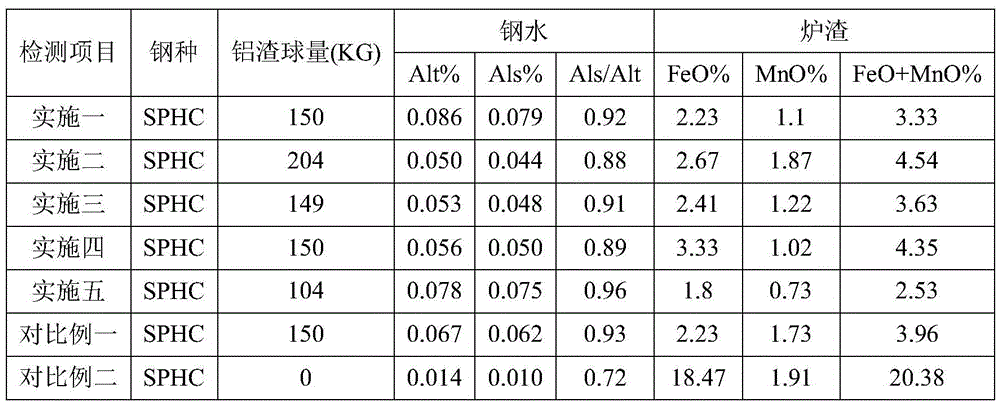

Embodiment 1

[0027] Al Al 2 o 3 SiO 2 CaF 2 CaO h 2 o 50 9.0 4.2 7 22 0.4

Embodiment 2

[0029] Al Al 2 o 3 SiO 2 CaF 2 CaO h 2 o 50 9.9 5.0 7.5 20 0.2

Embodiment 3

[0031] Al al 2 o 3 SiO 2 CaF 2 CaO h 2 o 48 9.5 4.7 10 24 0.5

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a high-calcium-aluminum slag ball. The high-calcium-aluminum slag ball comprises metallic aluminum (Al), aluminum oxide (Al2O3), silicon dioxide (SiO2), calcium fluoride (CaF2), calcium oxide (CaO), water (H2O) and other inevitable impurities. The component of the slag ball comprises, by weight, 48 parts to 52 parts of the metallic aluminum, 9 parts to 9.9 parts of aluminum oxide, 4 parts to 5 parts of silicon dioxide, 5 parts to 10 parts of calcium fluoride, 20 parts to 24.9 parts of calcium oxide and 0.2 part to 0.5 part of water. When low-carbon steel is smelted, in the steel tapping process, a certain number of high-calcium-aluminum slag balls are added, and therefore, the soluble aluminum proportion in molten steel can be greatly improved, and the contents of ferric oxide and manganese oxide are reduced, and cleanness of the molten steel is improved; and by means of the high-calcium-aluminum slag balls, the deoxidization effect is good, steel slag fluidity is improved, the slag remanufacturing requirement of the refining process is met, and meanwhile, the production cost can be reduced.

Description

technical field [0001] The invention relates to the technical field of pre-treatment alloying of molten steel refining, and more specifically relates to a high-calcium-aluminum slag ball capable of alloying molten steel and improving the properties of steel slag during refining treatment and a preparation method thereof. Background technique [0002] Improving the purity of steel is conducive to improving steel quality, improving steel performance and prolonging the service life of steel. It is an important development direction of steel products in the "Twelfth Five-Year Plan". The research and development of high-efficiency, low-cost, and stable production of high-clean steel production technology will be the focus of steelmaking technology development in the future. Refining is an important means to improve the purity of molten steel. In order to make the molten steel clean, it is necessary to deeply remove impurities from the molten steel. The premise of the removal of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C21C7/06C21C7/076

CPCC21C7/06C21C7/076Y02P10/20

Inventor 程俊岭王煜

Owner BEIJING ANTAI YONGSHENG METAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com