Preparation method and use of morphology-variable inorganic-organic composite inverse opal structure photonic crystal

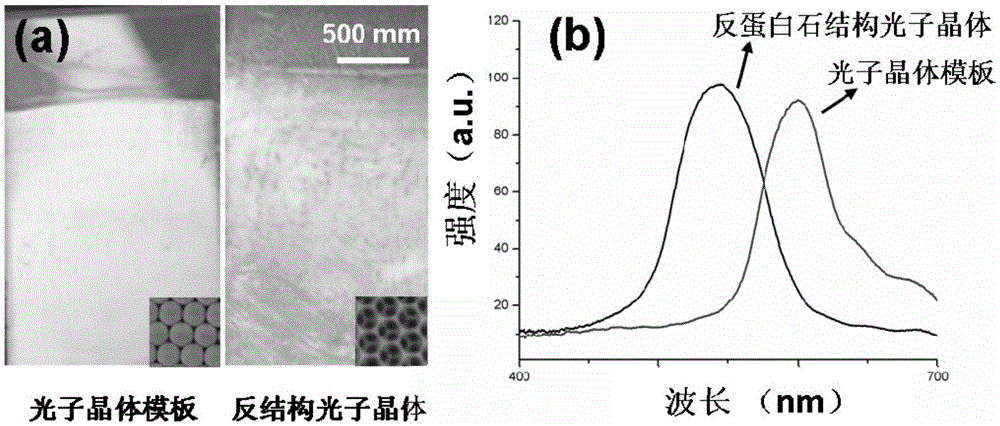

An inverse opal structure and photonic crystal technology, applied in crystal growth, chemical instruments and methods, single crystal growth, etc., can solve problems such as long preparation period, limited material application fields, and structural evolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

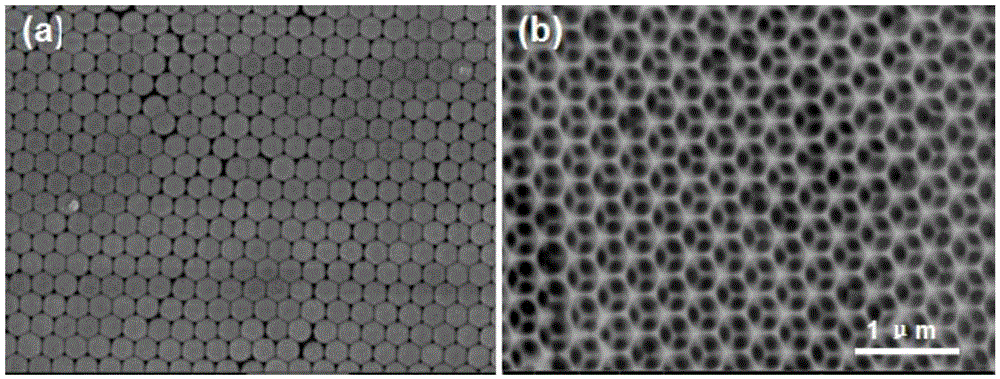

[0051] 1) Disperse monodisperse styrene-methyl methacrylate-acrylic acid polymer microspheres with a particle size of 265nm in water to form a 10wt% emulsion, control the temperature at 20°C, and use a vertical deposition method at a relative humidity of 10% Let the polymer microspheres self-assemble into a film on the substrate, the assembly time is 48h, as a photonic crystal template;

[0052] 2) Use plasma to carry out hydrophilic treatment on the photonic crystal template for 1 min;

[0053] 3) Dissolve lead nitrate in deionized water to prepare a concentration of 200mmol / L. After the dissolution is complete, add an appropriate amount of the solution dropwise on the surface-treated photonic crystal, and place it at room temperature of 20°C until the solvent evaporates and the metal salt crystallizes.

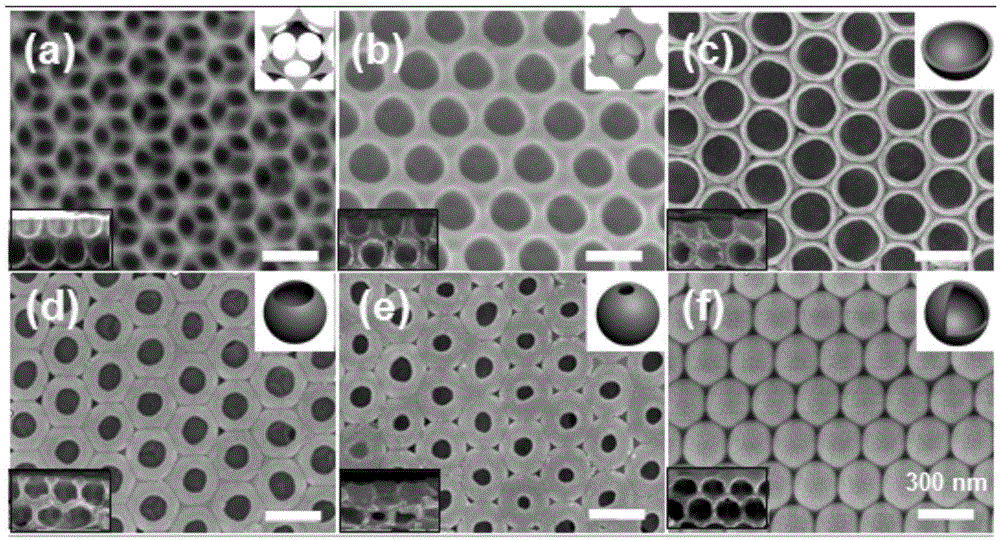

[0054] 4) Put the filled photonic crystal template into toluene to remove the template, while removing the template, the polymer microspheres interact with the metal salt to...

Embodiment 2

[0056] 1) Disperse monodisperse styrene-methyl methacrylate-acrylic acid polymer microspheres with a particle size of 180nm in water to form a 30wt% emulsion, control the temperature at 60°C, and the relative humidity at 60%, using a vertical deposition method Let the polymer microspheres self-assemble into a film on the substrate, the assembly time is 24h, as a photonic crystal template;

[0057] 2) Use plasma to treat the photonic crystal template for hydrophilization for 10 minutes;

[0058] 3) Metal salt CuSO 4 or ZnSO 4 Dissolve in deionized water to prepare a concentration of 80mmol / L. After the dissolution is complete, add an appropriate amount of the solution dropwise on the surface-treated photonic crystal, and place it at room temperature of 20°C until the solvent evaporates and the metal salt crystallizes.

[0059] 4) Put the filled photonic crystal template into tetrahydrofuran to remove the template, and at the same time, the polymer microspheres interact with t...

Embodiment 3

[0061] 1) Disperse monodisperse styrene-methyl methacrylate-acrylic acid polymer microspheres with a particle size of 265nm in water to form a 20wt% emulsion, control the temperature at 60°C, and the relative humidity at 80%, using a vertical deposition method Let the polymer microspheres self-assemble into a film on the substrate, the assembly time is 26h, as a photonic crystal template;

[0062] 2) Use plasma to carry out hydrophilic treatment on the photonic crystal template for 2 minutes;

[0063] 3) Metal salt Pb(NO 3 ) 2 Dissolve in deionized water to prepare a concentration of 250mmol / L. After the dissolution is complete, add an appropriate amount of the solution dropwise on the surface-treated photonic crystal, and place it at room temperature of 20°C until the solvent evaporates and the metal salt crystallizes.

[0064] 4) Put the filled photonic crystal template into dioxane to remove the template, and at the same time the template is removed, the polymer microsphe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com