Low temperature dyeing process of wool fabric

A low-temperature dyeing and fabric technology, applied in the field of low-temperature dyeing technology, can solve the problems of cumbersome process steps, low wool pretreatment rate, and long time consumption, and achieve smooth hand feeling and bright color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

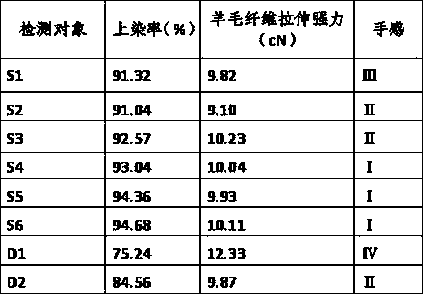

Examples

Embodiment 1

[0027] The low-temperature dyeing process of the woolen fabric of embodiment 1 (abbreviated as S1, the following embodiments are the same) comprises the following steps:

[0028] S1: Prepare the dye mixing solution, which contains reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator, ionic liquid and water. The weight ratio of wool fabric to reactive dyes is 1:0.02; soluble chlorine The rare earth element in the rare earth chloride is at least one selected from light rare earth and medium rare earth, the weight ratio of the wool fabric to the rare earth chloride is 1:0.001, the pH value of the dye mixing solution is 4.5, and the wool fabric and the ionic liquid The weight ratio is 1:0.15; the pH regulator is citric acid; the soluble rare earth chloride is lanthanum chloride; the weight ratio of wool fabric to sodium sulfate is 1:0.004; the ionic liquid is 1-butyl-3-methanol Kiimidazolium chloride sub-liquid;

[0029] S2: Immerse the wool fabric in the dye ...

Embodiment 2

[0034] The difference between embodiment 2 and embodiment 1 is:

[0035] S1: Prepare the dye mixing solution, which contains reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator, ionic liquid and water, and the weight ratio of wool fabric to reactive dyes is 1:0.045; The rare earth element in the soluble rare earth chloride is at least one selected from light rare earth and medium rare earth, the weight ratio of wool fabric to rare earth chloride is 1:0.005, the pH value of the dye mixing solution is 5.5, and the wool fabric and ion The weight ratio of the liquid is 1:0.35; the pH regulator is acetic acid-sodium acetate buffer pair; the soluble rare earth chloride is a mixture of neodymium chloride and gadolinium chloride chloride, and praseodymium chloride accounts for the weight of the soluble rare earth chloride The percentage is 50%; the weight ratio of wool fabric to sodium sulfate is 1:0.005; the dye mixture solution also includes a leveling agent, whic...

Embodiment 3

[0041] The difference between embodiment 3 and embodiment 1 is:

[0042] S1: Prepare the dye mixing solution, which contains reactive dyes, sodium sulfate, soluble rare earth chloride, pH regulator, ionic liquid and water, and the weight ratio of wool fabric to reactive dyes is 1:0.032; The rare earth element in the soluble rare earth chloride is at least one selected from light rare earth and medium rare earth, the weight ratio of the wool fabric to the rare earth chloride is 1:0.003, the pH value of the dye mixing solution is 5, the wool fabric and ion The weight ratio of the liquid is 1:0.25; the pH adjusting agent is a citric acid-sodium citrate buffer pair; the soluble rare earth chloride is a mixture of praseodymium chloride and samarium chloride, and the praseodymium chloride accounts for the weight of the soluble rare earth chloride The percentage is 20%; the weight ratio of wool fabric to sodium sulfate is 1:0.02; the weight ratio of wool fabric to leveling agent is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com