Photoetching method and device of roll to roll flexible substrate

A flexible substrate and roll flexible technology, which is applied in photolithography exposure devices, microlithography exposure equipment, optics, etc., can solve the problems of inability to realize the patterning process of TFT array substrates and high precision of patterning alignment, and achieve Save process equipment costs, improve yield and production tact, and improve the effect of production tact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Preferred embodiments of the present invention are described in detail as follows:

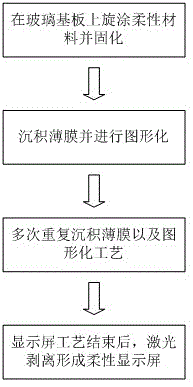

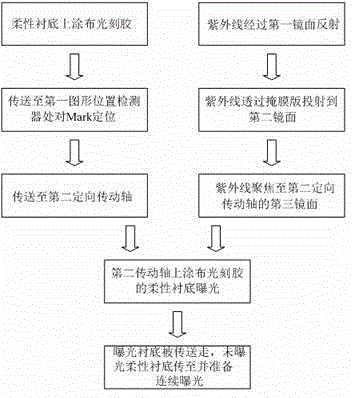

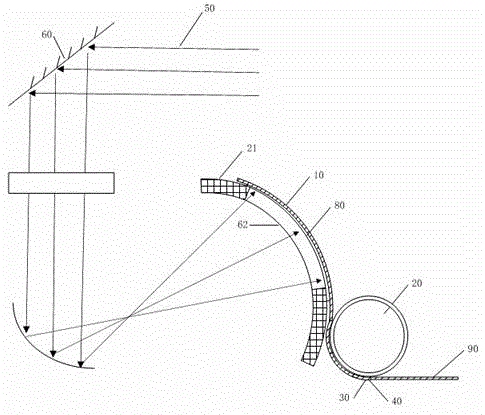

[0026] In this example, see figure 2 and image 3 , a roll-to-roll flexible substrate lithography device, mainly composed of an ultraviolet light source 50, a flexible substrate conveying system and a photoresist coating device, the photoresist coating device coats photoresist on the flexible substrate 10 80. The flexible substrate transfer system is mainly composed of the first directional transmission shaft 20, the second directional transmission shaft 21 and the corresponding transmission shaft drivers. After the photoresist 80 is coated on the flexible substrate 10, the photoresist 80 will be coated One side of the flexible substrate 10 is wound onto the surface of the first orientation transmission shaft 20, and the flexible substrate 10 part coated with photoresist 80 is transported to the substrate film pattern manufacturing position by driving the first orientation transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com